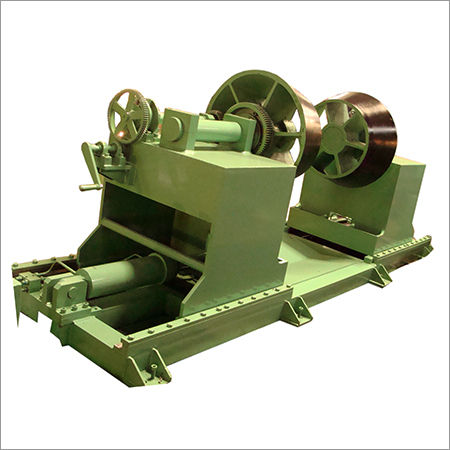

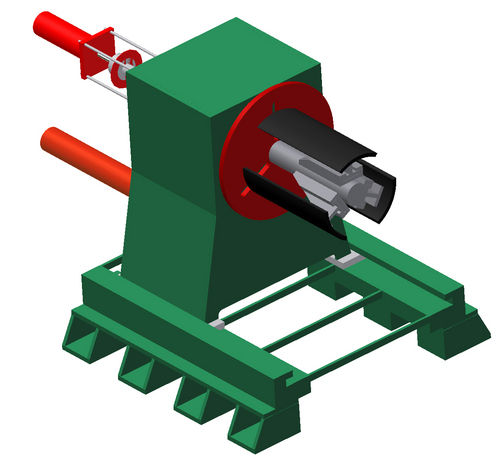

Vertical Decoiler - High Tensile Strength, Rigid Non-corrosive Metal Body | Minimal Maintenance, Easy Operation, Motorized Soft Start & Stop System, Optional Hydraulic Jaws Expansion

Price:

Get Latest Price

In Stock

Product Specifications

| Drive System | Ac Motor |

| Material | Steel |

| Color | Green |

| Jaws | 3 Or 4 |

| Bearings | Anti-Friction |

| Brake | Drag Brake |

| Features | Rigid Construction, Minimal Maintenance, High Tensile, User Friendly, Non-Corrosive, Easy Operation, Timely Delivery, Negligible Maintenance |

Product Overview

Key Features

Having attained a reputable name in the industry, we are committed to manufacture and supply Vertical Decoiler. Although the offered machine is technically advanced, it is designed in a way that makes it easy to use. All components that are integrated into the machine are sourced only after thorough checking. Owing to our vast distribution network, we assure timely delivery of Vertical Decoiler at clients destined location.

Features:

- Minimal maintenance

- Rigid construction

- Non-corrosive

- High tensile strength

Other details:

These are offered with following features:

- The spindle & coil holding heads housed in mechanical & ground housing and it rotates on dust proofed sealed bearing element

- All motorized de-coilers are chain driven soft start & stop through mechanical torque limiter & friction drag brake

- Drive System: A.C. fixed speed and variable speed (optional)

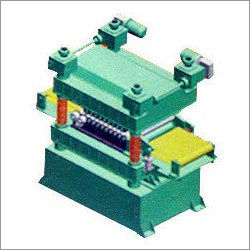

- Control panel with suitable loop control system to maintain loop of coil for the machine via antenna type loop sensors, limit arm through limit switches and photo sensors

Available options:

- All units are available is non motorized version with drag brake

- Electro magnetic or pneumatic brake

- Coil hold-down (hydraulic or pneumatic) for springy material

- Hydraulic jaws expansion

- De-coilers with shafting & key to load bobbin.

Company Details

Business Type

Manufacturer, Service Provider, Supplier

Employee Count

10

Establishment

2000

Working Days

Monday To Saturday

GST NO

06AAQPY0989A1Z9

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 06AAQPY0989A1Z9

Gurugram, Haryana

Managing Director

Mr J.s S Yadav

Members since

4 Years

Address

Plot No. 39790, Daultabad Industrial Area, Gurugram, Haryana, 122001, India

Report incorrect details