Industrial Recoiler

Price:

Get Latest Price

In Stock

Product Specifications

| Primary Color | Green |

| Type | Coil Recoiler |

| Capacity | 2.5-3.0 tonnes |

| Brake Type | Electromagnetic/Pneumatic |

| Jaws | 3-4 self-centering |

| Drive System | AC fixed/variable speed |

| Material | Fabricated steel |

| Usage | Metal coil unwinding and feeding in industrial processes |

| Features | Sturdy built, User-friendly, Low maintenance, Simple operation, Versatile usage |

Product Overview

Key Features

We are supported by technically profound engineers who enable us to manufacture and supply Industrial Recoiler. Offered in non-motorized version with drag brake, it is appreciated by clients for simpler operations and suitability to serve needs of different industry segments. In order to meet the specific demands of clients, it is made available with electromagnetic or pneumatic brakes. To assure its compliance with international quality standards, Industrial Recoiler is passed through stringent check on several predefined parameters.

Features:

- Sturdy built

- Technically advanced

- User-friendly

- Low maintenance

Other details:

Technical specifications:

- Sturdy fabricated structure

- Three or four self centering coil-location jaws, with mechanical gear reducer for models 2.5 tonnes / 3.0 tonnes

- The spindle & coil holding heads housed in mechanical & ground housing & rotate on dust proofed sealed bearing element

- All motorized de-coilers are chain driven soft start & stop through mechanical torque limiter & friction drag brake

- Drive System: A.C. fixed speed and A.C. variable speed (optional)

- In twin spindle de-coiler, two mandrels are housed on a turret and turret is supported on anti friction bearings for reducing friction while indexing.

- Turret is locked by spring loaded plunger 7 released by foot pedal (This is for quick coil changeover & saving coil loading time)

- Control panel with suitable loop control system to maintain loop of coil for the machine via antenna type loop sensors/limit arm through limit switches / photo sensors

Available options:

- Electro Magnetic or Pneumatic Brake

- Coil hold-down (hydraulic or pneumatic) for springy materials

- Hydraulic Jaws Expansion

- De-coilers with Shafting & Key to load bobbin

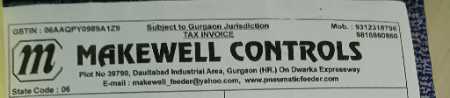

Company Details

Business Type

Manufacturer, Service Provider, Supplier

Employee Count

10

Establishment

2000

Working Days

Monday To Saturday

GST NO

06AAQPY0989A1Z9

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 06AAQPY0989A1Z9

Gurugram, Haryana

Managing Director

Mr J.s S Yadav

Members since

4 Years

Address

Plot No. 39790, Daultabad Industrial Area, Gurugram, Haryana, 122001, India

Report incorrect details