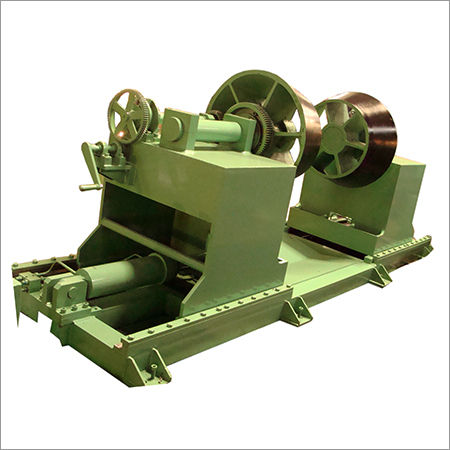

Large Width Decoiler - Heavy Duty Structure, 2.5 To 3.0 Tonne Capacity | Energy Efficient, Easy To Operate, Low Maintenance

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Stainless Steel |

| Dimensions | Variable |

| Capacity | Customizable |

| Pressure | Variable |

| Temperature | Variable |

| Columns | Multiple |

| Trays | Multiple |

| Features | High Efficiency, Long Lifespan, Easy Operation, Durable Design, Corrosion Resistant, Cost Effective, Precise Distillation |

Product Overview

Key Features

Strengthened by world-class infrastructural facility, we are manufacturing and supplying Large Width Decoiler. Designed by experienced engineers, it is integrated with advanced features that make it ideal to uncoil metal wires and strips for longer working hours. It is not only available in standard version, but also fabricated with several particular specifications needed by clients to achieve their complete satisfaction. Prior to its delivery, Large Width Decoiler is subjected to stringent quality checks to ascertain its flawlessness.

Features:

- Low maintenance

- Energy efficient

- Easy to operate

- Hassle-free functioning

Other details:

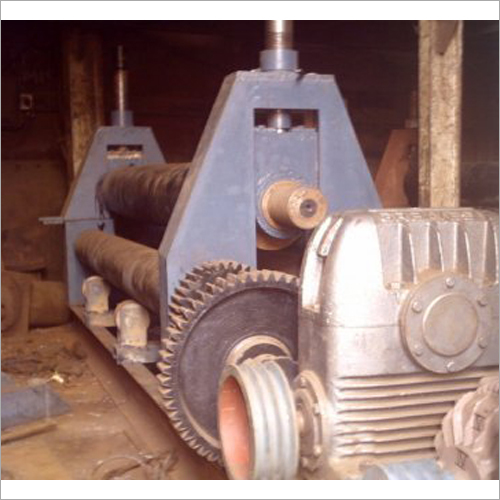

- The Spindle & Coil holding heads housed in mechanical & ground housing & rotate 4s on dust proofed sealed bearing element.

- All motorized decoilers are chain driven soft start & stop through mechanical torque limiter & friction drag brake.

- Drive System: A.C. Fixed Speed/A.C. Variable Speed (optional)

- Control panel with Suitable loop control system to maintain loop of coil for the machine via Antenna Type loop sensors or limit arm through limit switches or photo sensors

- In Twin Spindle Decoiler, two mandrels are housed on a Turret and Turret is supported on anti friction bearings for reducing friction while indexing. Turret is locked by spring loaded plunger 7 released by foot pedal. (This is for quick coil-changeover & saving coil loading time.

Option :

- All units are available is non motorized version with drag brake.

- Electro Magnetic or Pneumatic Brake.

- Coil hold-down (hydraulic or pneumatic) for springy materials.

- Hydraulic Jaws Expansion

- Decoilers with Shafting & Key to load bobbin.

- Other Special features on demand.

Company Details

Business Type

Manufacturer, Service Provider, Supplier

Employee Count

10

Establishment

2000

Working Days

Monday To Saturday

GST NO

06AAQPY0989A1Z9

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 06AAQPY0989A1Z9

Gurugram, Haryana

Managing Director

Mr J.s S Yadav

Members since

4 Years

Address

Plot No. 39790, Daultabad Industrial Area, Gurugram, Haryana, 122001, India

Report incorrect details