Product Overview

Key Features

Trusted for the quality of our products, our organization is actively manufacturing and supplying Twin Motorized Decoiler. Our professionals make use of fine quality materials and latest machinery to obtain the final output in close proximity with the quality standards set by the industry. As required by clients, it is offered with an option of non-motorized version, electromagnetic or pneumatic brakes along with hydraulic jaws expansion. Twin Motorized Decoiler is reckoned in the market for the following features: Robust construction Consistent performance Easy to maintain Simple to operate Other details:We are engaged in manufacturing and exporting of a wide range of user friendly De-Coilers that has user friendly design and is available in cost effective prices. These de-coilers are available with spindle & coil holding heads housed in mechanical & ground housing & rotates on dust proofed sealed bearing element. Moreover, their control panel has suitable loop control system to maintain loop of coil for the machine via antenna type loop sensors or limit arm through limit switches or photo sensors. The product includes: Rigid fabricated structure Three or four self centering coil-location jaws, with mechanical gear reducer for models 2.5 tonnes / 3.0 tonnes The spindle & coil holding heads housed in mechanical & ground housing & rotates on dust proofed sealed bearing element All motorized de-coilers are chain driven soft start & stop through mechanical torque limiter & friction drag brake Drive System: A.C. fixed speed or A.C. variable speed (optional) In twin spindle de-coiler, two mandrels are housed on a turret and turret is supported on anti-friction bearings for reducing friction while indexing. Turret is locked by spring loaded plunger & released by foot pedal. (this is for quick coil changeover & saving coil loading time Option : All units are available is non motorized version with drag brake Electro magnetic or pneumatic brake Coil hold-down (hydraulic or pneumatic) for springy material Hydraulic jaws expansion De-coilers with shafting & key to load bobbin

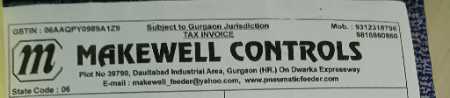

Technologically advanced Mechanical Gripper Feeders, Pneumatic Feeders, De-Coilers, Straightener cum De-coilers, Strip Straighteners, etc. made available under one roof....Automation has revolutionized all those areas in which it has been introduced, and there is scarcely an aspect of modern life that has been unaffected by it. At Makewell Controls, our people are devoted to power press automation and in the process, improve our clients' competitive ability. It is owing to our commitment towards client satisfaction that we continue to set new standards in the automation technology. Our company is a leading manufacturer and supplier of Mechanical Gripper Feeders, Pneumatic Feeders, Re-Coilers, Straightener cum De-coiler