Automatic Strips Auto-butt Welding Machine

Price: 10000 USD

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Type | Automatic |

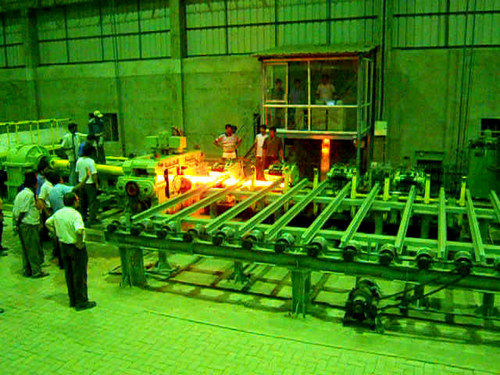

| Usage | Used to butt weld strips head and tail together in ERW pipe mill line, cold roll forming mill line in continue production. |

| FOB Port | FOB CHINA SEAPORT |

| Payment Terms | Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T) |

| Delivery Time | 30 Days |

Product Overview

Key Features

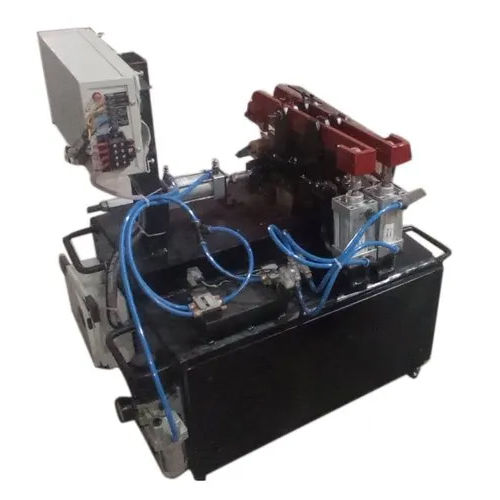

Metal Strip Material Automatic Shear Welder

It can be used for steel welding pipe production, continuous stamping production and other production. It can be finished the welding work of strip material(including stainless steel, carbon steel, galvanized strip, copper, aluminum).

1.Adopt advanced shear process without burr.

2.It is easy to work for hydraulic pressure as power.

3.Clamping plank and keeping the level, all these controlled by foot switch

4.Use tungsten TIG welding; The welding seam is small without polishing. And it is high strength.

5.Automatic for welding.

Parameters

1.Strip thickness 0.7~4.0mm

2.Strip width 40~360mm

3.Welding torch speed 0~50mm/min

4.Welding current 16~400A

5. 3P 440V

6.Argon working pressure 0.2~10Mpa

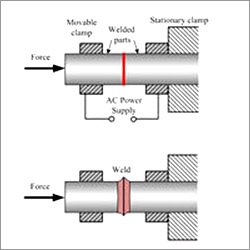

Structure and operation

1. Adopt oblique shear; Two down knives should be fixed on the down knife base. The base connected the frame by screws. The up knife should be installed on the moved frame. There is oil tank to move for up knife support frame.

2.Tighten; The position should be on the frame. Make two strips to keep the level and press; Tighten the position to make right and left parts; It can be controlled the air cylinder by foot switch.

3.To butt joint of right and left two pieces of strip, clamping the middle of copper electrode plates by clamping device ;The welding torch should be fixed on the moved slider, It can be drive by screw shaft.

4.The screw shaft drive by motor; The motor can be adjusted speed by the inverter output frequency, then adjust the speed of welding torch.

5.The whole welding is controlled by a proximity switch; The welding torch moved ;The argon arc welding machine is controlled by electric cabinet, and it is automatically welding.

6.The indicator is light for right and left , it shows pressing tightly. on the contrary, it sends the materials.

7.It can be controlled by foot switch for right and left tight; The device will be move for foot action.

8.The shear foot switch is in the middle; The up knife will cut down for pressing the switch; Then the up knife will be back for loosening the switch.

9.Close switch control the arc strike, arc failure and return of welding torch. Adjust the sensor on the welding torch moving sheet, make the distance 1-3mm to cause sensing signal; The arc strike and the arc failure time had adjusted before delivery. Adjust method: arc strike at edge 1-2.5mm;arc failure at edge 0.5-4mm.

10.Motorized button: there are front and back buttons; it can be adjusted the welding torch position by hand. Position by the indicator.

Company Details

Focusing on a customer-centric approach, TAIYUAN ROLLED MILL TRADE CO. LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Welding Machine in bulk from TAIYUAN ROLLED MILL TRADE CO. LTD. at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

6

Establishment

2007

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Taiyuan, Shanxi

Accepts only Foreign inquiries

General Manager

Mr. Sun Yuqing

Address

186th Floor, Unit 1, 199# Building 1 Xiangtangbei Street, Xinghualing District, Taiyuan, Shanxi, 030009, China

butt welding machine in Taiyuan

Report incorrect details