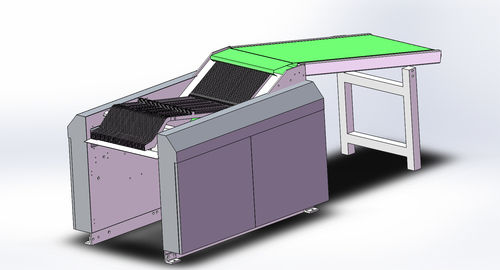

Stacking Machine - Stainless Steel, 39" Wide X 48" High, 120" Length | Heavy-duty Design, Independent Heater Units, Adjustable Band Edge Screens, Efficient Heat Transfer System

Price:

Get Latest Price

In Stock

Product Specifications

| Plant Width | 800mm, 1000mm, 1200mm |

| Wire Band Width | 812mm, 1016mm, 1220mm |

| Heater Unit Outside | 2850mm, 3050mm, 3370mm |

| Outside Width | 2215mm, 2415mm, 2615mm |

| Oven Height | 1926mm |

| Heater Unit Height | 2800mm |

| Material | Mild steel, stainless steel |

| Features | Efficient stacking, Heavy-duty design, Precise control, Durable materials, Easy operation, High capacity, Consistent results, Reduced waste |

Product Overview

Key Features

Stacking Machine

| ||||||||||||||||||||||||||||||

| | ||||||||||||||||||||||||||||||

| Specifications | ||||||||||||||||||||||||||||||

| Plant width inches (mm) A Wire band width inches (mm) B Heater unit outside inches (mm) C Outside width inches (mm) D Oven height inches (mm) E Heater unit height inches (mm) 32" (800) 32" (812) 112" (2850) 87" (2215) 76" (1926) 110" (2800) 39" (1000) 40" (1016) 120" (3050) 95" (2415) 76" (1926) 110" (2800) 48" (1200) 48" (1220) 128" (1370) 103" (2615) 76" (1926) 110" (2800) | ||||||||||||||||||||||||||||||

| Features | ||||||||||||||||||||||||||||||

| Oven length divided into suitable zones of varying lengths. Separate Heater Unit for each zone Heavy-duty structure made from thick, bent sheets of mild steel Heater Units with burner tubes, inlet ducts etc. in stainless steel. Units fitted with top and bottom distribution and turbulence ducts Side baking chambers fitted with cross turbulence tubes which are closer to wire band for faster and efficient heat transfer Wire band supported on chilled and hardened top surface. C. I. skids for longer life Band edge screens are adjustable from outside to control the colour of the end rows of biscuits Expansion joints between baking chamber in stainless steel Feed End fitted with mechanical tensioning system for tensioning of wire band. Drums of 40" dia.made from thick mild steel plates, stress-relieved and provided with camber for better tracking Delivery End with integrated Stripper Conveyor and Rejected Biscuit Conveyor Wire band driven by Delivery End Drum through geared motor Extraction fan at Delivery End of Oven Band Cleaning Unit provided with separate top and bottom brushes and flapper unit Outer Sheets of Oven are of lift-off type Electric panel as per IP 55 specifications with all electrical switch gear & digital baking clock Insulation of L. R. B. slabs in 225 mm thickness on all sides having density of 100 kg per cubic meter | ||||||||||||||||||||||||||||||

| Options | ||||||||||||||||||||||||||||||

| Outer Sheets made from mild steel (powder coated) or stainless steel For Ovens with baking chambers greater than 220 feet length, both the drums can be of 44" dia Oil / gas fired versions available | ||||||||||||||||||||||||||||||

Company Details

Focusing on a customer-centric approach, PREMIUM ENGINEERS has a pan-India presence and caters to a huge consumer base throughout the country. Buy Biscuit Making Machinery in bulk from PREMIUM ENGINEERS at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

25

Establishment

2005

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Ambala, Haryana

Proprietor

Mr. Pawan Bimbra

Address

No-379, Modern Automobiles, Model Town, Dist., Ambala, Haryana, 134003, India

biscuit stacking machine in Ambala

Report incorrect details