Pvc Pipe Threading Machine - Automatic Design For Bsp, Npt, And Acme Threads | Robust Hss Tangential Cutters, Precise Threading Performance

Price:

Get Latest Price

In Stock

Product Specifications

| Features | Precise Threading, Durable Design, Easy Operation, High Efficiency, Long Lifespan, Versatile Use, Reliable Performance, Cost-Effective |

Product Overview

Key Features

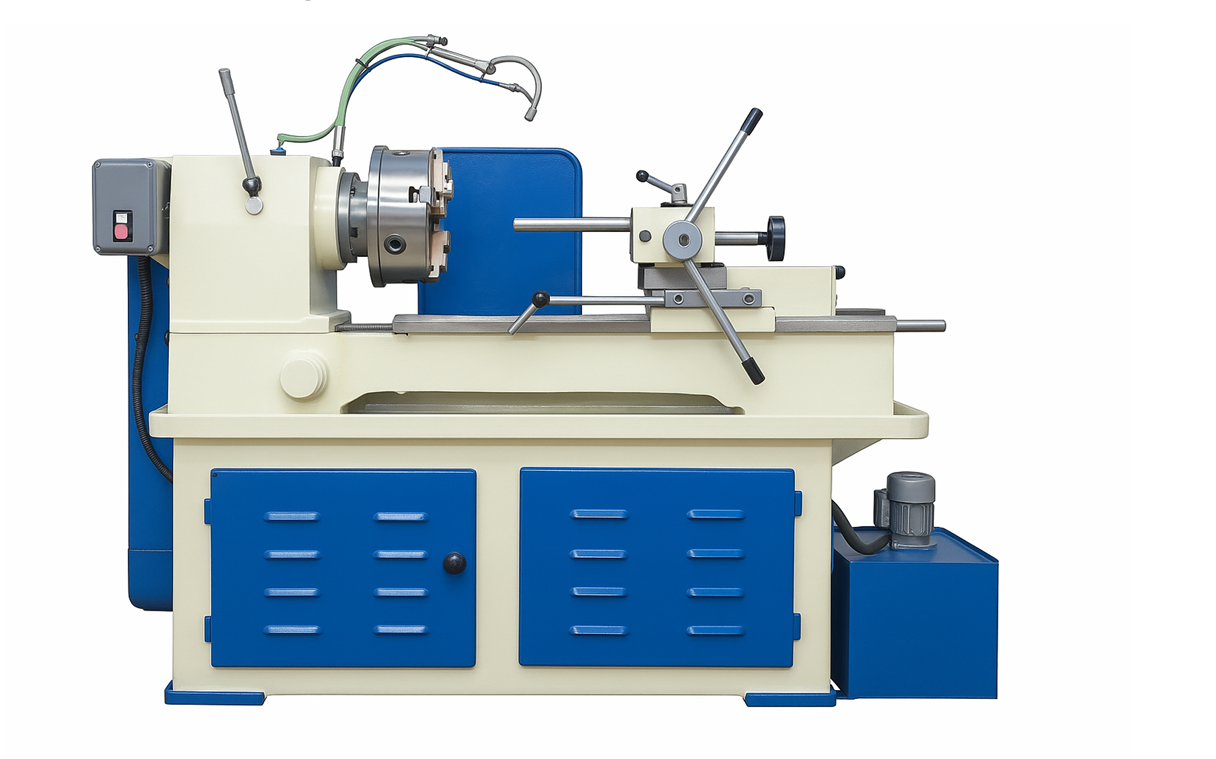

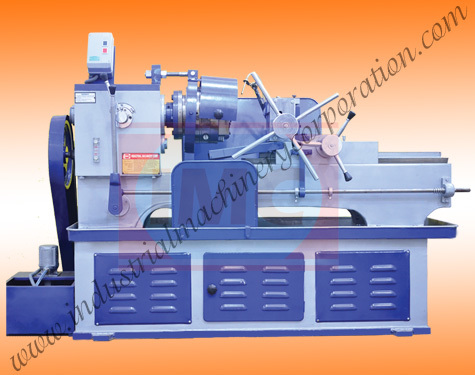

PVC Pipe Threading Machine

We are reckoned in this domain as an eminent manufacturer and exporter of PVC Pipe Threading Machine. Machines offered by us are engineered by our adroit professional using superlative quality raw materials and latest equipments at our state-of-art production unit. PVC Pipe Threading Machine offered by us is widely used in industries for cutting external thread on PVC pipes. This range of threading machine is widely popular for its attributes such as robust construction, precise performance and long service life.

| Quick Buyer Details | |

| Business Type: | Exporter , Manufacturer , Supplier |

| Place of Origin: | Ludhiana, Punjab, India |

| Brand Name: | IMC |

| Year of Establishment: | |

| Production Type: | Automatic |

| Type: | Thread Cutting Machinery |

| Export Markets: | Australia/NZ Indian Subcontinent Caribbean East/Middle Africa North Africa South/West Africa East Europe East Asia Central America North Europe Middle East South America South/West Europe South East Asia North America |

| Certification: | ISO 9001:2008, Verified by TradeIndia | Trust Stamp |

| Turnaround Time: | 24-48 hours |

| Application: | Cut Matric, BSP, BSPT, NPT, UNF,UNC, BSW, Acme Threads B.S.F etc. |

| Technical Specifications: | Base Head Stock Saddle Bed or Pillar Type Clamping Vice Die Head |

| Range of IMC Threading Machine: | 1/4" to 1" do/- 3/8" to 1.1/2" do/- 1/2" to 2.1/2" do/- |

| Packaging Detail: | |

| Delivery Detail: | |

| Primary Competitive Advantages: | Impeccable quality Competitive prices Prompt delivery schedule Complete client satisfaction |

Further Details:

PVC Pipe Threading Machine is used for Cutting External Thread on PVC Pipes by Chasing method. HSS Tangential Chasers are used as cutters. Pipe remains stationery and Die Head rotates. Matric, BSP, BSPT, NPT, UNF,UNC, BSW, Acme Threads B.S.F etc. threads can be cut on this machine depending upon the type of Chasers. The machine mainly consists the following:-

Base

Head Stock

Saddle

Bed or Pillar Type Clamping Vice

Die Head.

PVC PIPE THREADING MACHINES are designed to give maximum efficiency and reliable performance under the most severe conditions of service with minimum maintenance cost. All the necessary requirements are combined in this model to from the basic fundamentals of correct threading. All the gears are made of case hardened steel with extra large face with and tooth thickness and cut on hobbing machine for noiseless operation even at high speed. Naturally the are built with high standards of workmanship, material and quality so closely associated with COMPANY TRADITION.

DESIGN & WORKMANSHIP: The Industrial Machinery Corporation thread cutting machines are designed to produce quality threads within the to lerance for which they were intended.

HEAD STOCK: A heavy duty geared Head Box is of best quality casting providing support to the spindle bearings. The box is of gear type, lubricated, fitted with three extra heavy duty bearings.

THE BED: The bed is pillar type having two pillars made of best quality steel nicely finished & duly hard chrome plated in the most modern hard chrome plating unit.

THE SADDLE: The Saddle is fitted on two pillars very precisely. It runs on pillars very smoothly and accurately to the Head Stock alignment.

The APRON: The apron gives movement to the saddle with head transfer along with pillars through steel rack and pinion arrangements. It's all gears are made of best quality steel.

VICE JAWS: The vice jaws made from the best quality alloy steel are fitted on the saddle well aligned with the head stock center fitted in a heavy duty box type vice. The jaws are heat treated. The movements of jaws are controlled by a screw on the saddle.

Range of IMC Threading Machines and Die Heads.

1/4" to 1" do/-

3/8" to 1.1/2" do/-

1/2" to 2.1/2" do/-

Specifications:

| Model | 1/4" to 1" | 3/8" to 1.1/2" | 1/2" to 2.1/2" |

| Saddle Movement | 10" | 10" - 12" | 12" - 16" |

| Spindle Speed Range | 60-90 | 60-90 | 60-90-120 |

| Number of Spindle Speed | 2 | 2 | 2 or 3 |

| Threading Capacity | 1/4" to 1" | 3/8" to 1.1/2" | 1/2" to 2.1/2" |

| Production per Hour | 60-80 | 60-80 | 70-90 |

| H.P. Required | 3 H.P. | 3 H.P. | 7.5 H.P. |

| Lead Screw | Provided | Provided | Provided |

| Weight (KG) Aprox. | 500 | 550 | 990 |

Company Details

Business Type

Exporter, Manufacturer, Supplier, Trading Company

Employee Count

50

Establishment

2002

Working Days

Monday To Sunday

GST NO

03BXNPS2799K1ZN

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 03BXNPS2799K1ZN

Ludhiana, Punjab

Proprietor

Mr. Davinder Singh

Members since

14 Years

Address

Plot No. - 273 Alamgir Village Malerkotla Road, Ludhiana, Punjab, 141116, India

pipe threading machine in Ludhiana

Report incorrect details