Producer Gas Plants - Plc Controlled Automation System, Efficient Chemical & Gas Processing Solutions | Long Functional Life, Low Energy Consumption

Price:

Get Latest Price

In Stock

Product Specifications

| Dominant Color | Green |

| Gasifier Type | Fixed bed |

| Capacity | Variable |

| Fuel Type | Coal |

| Automation | PLC based |

| Safety | Foolproof |

| Usage | Chemical processing, gas storage, and further industrial operations |

| Features | Gas production, Energy efficient, Long lifespan, PLC controlled, Safe operation |

Product Overview

Key Features

We are efficiently manufacturing and supplying excellent functioning Producer Gas Plants. The offered gas plants are successfully designed under the supervision of our skilled

professionals by utilizing superior quality components as per current market standards.

These gas plants are developed for processing and storing chemicals and gases

for further operations. The offered gas plants are properly tested as

per set industry standards by our quality analysts. Furthermore, our

customers can easily avail these Producer Gas Plants from us at affordable price range.

Features:

- PLC based instrumentation system

- Long functional life

- Low energy consumption

Specifications:

The control of the plant is most operation friendly and will be made safe and foolproof against hazards and human error through proper automation and PLC based instrumentation system. The control philosophy of Producer Gas Plant supplied is delineated below:

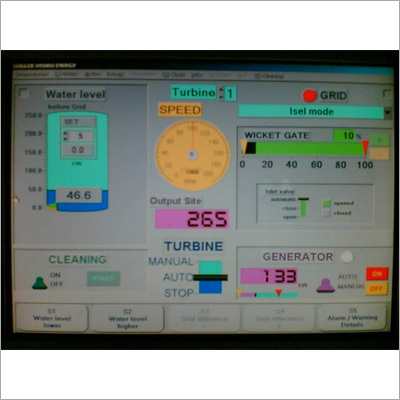

AUTOMATION AND CONTROLS

Gas producer , though a simple process, a small problem results in a long chronicle issue. That to with booster a special care is to be taken to avoid any abnormality. Our automation and control system is based on PLC with SCADA along with drives and Valves. The system has been designed to take care of the followings:

- Gas pressure control through VVF Drive.

- Steam air mix temperature control

- Air Pressure monitoring

- Vapour Drum Level monitoring and control

- Bottom seal water level monitoring and control

- Emergency over head water tank level monitoring and control

- Power pack oil level monitoring and alarm

- Power pack oil temperature monitoring and alarm

- Grate water level monitoring and control

- Zero pressure point monitoring of gas ( Gas header to Booster)

- Automatic shutdown process

- Closure of air blower valve and tripping the blower

- Opening of natural draft port

- Opening of chimney

- Flaring of gas through auto ignition system

- Auto blocking of gas by opening the water seal

- Auto blocking the poke hole air circulation

- Auto blocking the grate rotation

- Auto start up after shutdown lift off.

- Opening of air blower valve and start up the blower

- Closure of natural draft port

- Closure of chimney

- Shutdown of auto ignition system

- Releasing of gas by opening the water seal

- Releasing of poke hole air circulation

- Releasing of grate rotation

Above procedures are being done as per the sequence designed by us. Sequences and controls are critical to avoid any abnormalities.

- Air Flow Monitoring

- Gas outlet temperature monitoring.

- Gas out let Pressure monitoring

- Scrubber water flow monitoring

- Air blower, feed water pump, Phenol water pump running hours monitoring and maintenance schedule.

All the above automations will be through PLC and computer based.

Details of Automation

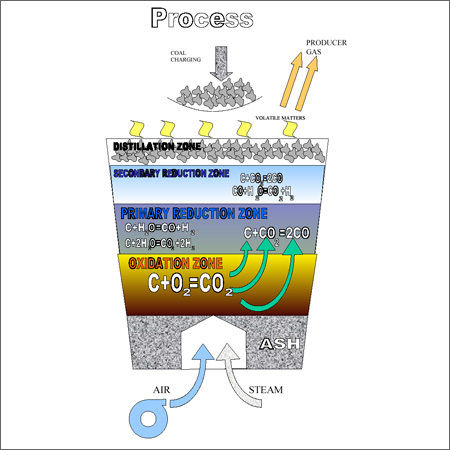

i) Control of coal feed as per demand

The gas will come out through two L.T.C pipes of each gasifier at a temperature of 120A A C to 140A A C. As Coal bed in the Extended Shaft comes down, the temperature of L.T.C pipes tends to come up. A temperature switch is Set at a temperature of 140A A C. As L.T.C temperature touches 14A A C, the switch actuates three pneumatic power cylinders at sector gate and two Bell Cones which open sequentially 1st the sector gate for about 30 Secs. (or as adjusted) and then the 1st Bell Cone after the sector gate is closed and lastly the second Bell Cone after 1st Bell Cone is closed. Thus coal is fed into the gasifier. If after 5 minutes of coal charging, the temperature does not come down below the set value, the coal feeding will be repeated.

ii) Control of Producer Gas output as per heat demand

A differential Pressure Transmitter will be fitted at the outlet gas header after the washing chamber and before the suction of the Gas Booster, which will control the gas pressure right from Booster suction down to the gasifier by controlling the air flow to the gasifier. Air is the primary variable for increasing or decreasing the gas output. As the consumption of gas increases, the gas header pressure decreases. With decrease of header pressure from the set value, the opening of controller in the air header after the air blower increases and in tune increases the air output. More air increases the reaction rate and gas output and thus system pressure is maintained with more gas flow to the consumption points. The reverse sequences of operation follow with decrease in gas consumption. Thus with decrease of consumption, there is no necessity of bleeding the generated gas through the chimney valve, but the gas generation automatically decreases to maintain the pressure and at the same time saves the fuel and energy costs.

iii) Control of B.S.T by Controlled Steam addition for

optimization of gasification.

Similar to addition of air, which controls the gas output, regulated addition of steam is most important for optimization of steam carbon reactions for optimum formation of CO and H2, correct bed temperature and prevention of clinker formation. For D/E grade coal, a BST of 62A A C to 65A A C is ideal. By setting the BST at desired level through a temperature switch fixed at a suitable point on the saturated air line after steam addition, the controller on the steam line will automatically open or close with increase or decrease of air flow to maintain the BST at a temperature as desired. All these are controlled through PLC. However, if there is tendency of clinker formation, a little more steam is added over the optimum quantity by increasing the BST through PLC but keeping the air flow same which on the other hand determines the gas output and header pressure.

iv) Control of Feed water input and maintaining the level of

Vapour Drum

The soft water will be supplied from the soft water plant which will be stored in a soft water tank and the level of the tank will be maintained by a mechanical float valve. From this tank, water will be continuously pumped to an overhead tank of 6KL capacity and is of spill-return type. From this tank water will flow to the vapour drum of each gasifier through a control valve, which will automatically maintain the level of vapour drum at about 70%. There will be thermo-siphoned natural circulation of water through the jacket cooler and the control valve will automatically make up the depletion of level by steam generation.

v) Temperature and Pressure control

This has been explained in para No. (i) and (ii) above

vi) Automatic Ash Discharge

Rotation of Ash Bowl and slightly eccentrically positioned rotating grate helps removal of ash from the system. As reaction proceeds, coal bed moves down, oxidized and ash granules from the burnt coal gradually comes out to the ash pan after getting crushed by the eccentric rotation of the grate against the gasifier shell. While coming out through the water seal of the ash pan, it is cut by the ash plough placed at a suitable angle and automatically diverted out from the pan over to the moving belt conveyor. The rotating grate and bowl helps homogeneous settling of the coal bed for perfect and uniform draught condition, breaking of clinkers and easy movement of ash to the ash pan. The speed is intermittent for cutting out the ash by ash plough and generally takes place at an interval of about 2 hrs. which can be adjusted as per requirement in case of higher ash level. At this speed the grate and bowl make a complete round in about 40 to 45 minutes. Both these motions are created by hydraulic power pack. Over and above these automatic motions, a quick rotation can be manually done if the ash level comes up beyond normal height due to clinker formation and loss of flow ability. Level of ash can be known by poking rod at the time of poking. Ash bed must cover the grate rings and stool to save them from oxidation heat and buckling. Air and steam mixture flowing in through grate rings cools the ash and in turn gets preheated. Ash, automatically removed by rotating grate and bowl and the fixed plough, falls on a moving belt conveyor which carries it for loading a tractor-trailor through an over head chute.

vii) The water level controls at different point like Emergency tank, Bottom seal, and the vapour drum will be maintained automically using level transmitters and switches.

- Various annunciation and the safety parameters are monitored vide PLC and respective controls are taken through the same.

Company Details

Focusing on a customer-centric approach, ENGINEERING SERVICES has a pan-India presence and caters to a huge consumer base throughout the country. Get Industrial Gas Plants from ENGINEERING SERVICES at Trade India quality-assured services.

Business Type

Manufacturer, Service Provider, Supplier

Employee Count

40

Establishment

1984

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Howrah, West Bengal

Accepts only Domestic inquiries

Proprietor

Mr. Himachal Samanta

Address

13/12/1, Kankra Para Lane, Howrah, West Bengal, 711104, India

gas plants in Howrah

Report incorrect details