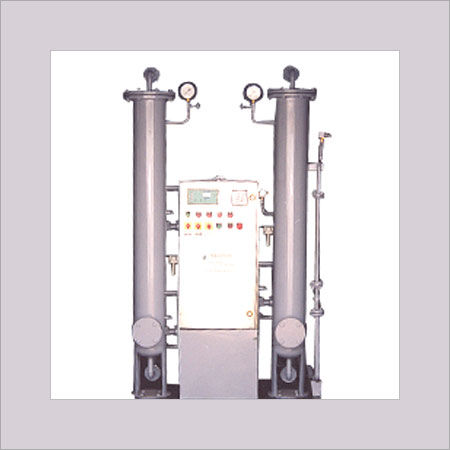

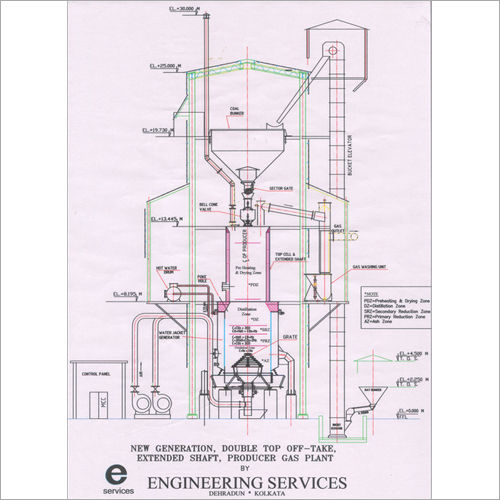

Extended Shaft Gasifier

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Steel |

| Dimensions | Variable |

| Gas Output | Variable |

| Air Input | Adjustable |

| Efficiency | High |

| Construction | Robust |

| Safety Features | Multiple |

| Features | Easy Operation Less Consumption Corrosion Proof Gas Control Emergency Shut Off Quick Resumption Flexibility Efficient Gasification |

Product Overview

Key Features

Normal

0

false

false

false

EN-US

X-NONE

X-NONE

LatentStyleCount="267">

/* Style Definitions */

table.MsoNormalTable

{mso-style-name:"Table Normal";

mso-tstyle-rowband-size:0;

mso-tstyle-colband-size:0;

mso-style-noshow:yes;

mso-style-priority:99;

mso-style-qformat:yes;

mso-style-parent:"";

mso-padding-alt:0in 5.4pt 0in 5.4pt;

mso-para-margin-top:0in;

mso-para-margin-right:0in;

mso-para-margin-bottom:10.0pt;

mso-para-margin-left:0in;

line-height:115%;

mso-pagination:widow-orphan;

font-size:11.0pt;

font-family:"Calibri""sans-serif";

mso-ascii-font-family:Calibri;

mso-ascii-theme-font:minor-latin;

mso-hansi-font-family:Calibri;

mso-hansi-theme-font:minor-latin;}

With the help of our expert

team we are manufacturing and supplying superior quality range of Extended Shaft

Gasifier. The offered shaft gasifiers are assembled by utilizing

finest quality components under the stern guidance of our skilled professionals

as well equipped production unit. This shaft gasifier is demanded for proper

gasification in obtaining numerous categories of gases. Prior to delivery this

gasifier is tested by our quality controllers as per standard parameters. The

offered Extended

Shaft Gasifier can be easily availed at economical price range.

Features:

Easy to

operateLess energy

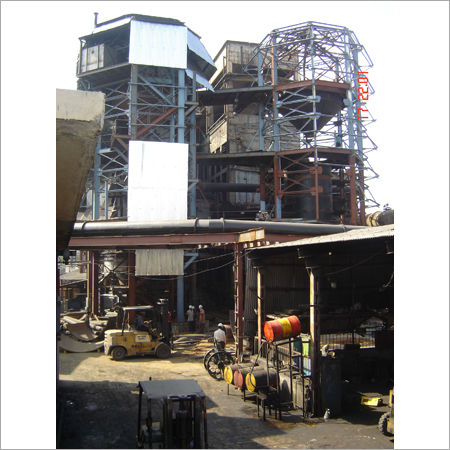

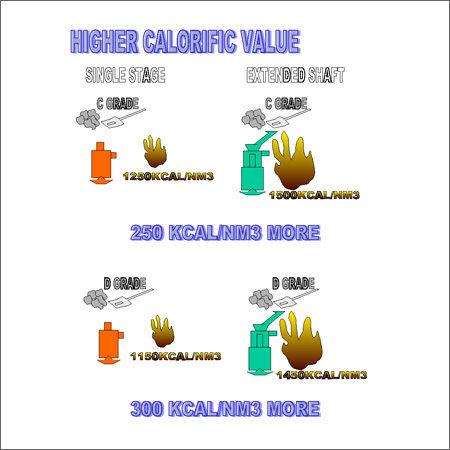

consumptionCorrosion proof structureSpecifications: This development was first started in a chemical plant at Dehradun which was producing very high quality of tooth paste grade precipitated CaCO3 from the Calcination of Dehradun Lime stone in a shaft kiln fired by producer gas from single stage gasifiers. The quality of Indian coal with higher and higher ash content started giving troubles and both quality and production of gas deteriorated. The authorities of the chemical plant who were originally owners of coal mines at Ranigung area of W.B. and had vast knowledge of coal characteristics and its gasification kinetics started modification of the gas producers with extended shaft in order to increase time of retention of feed coal for preheating and low temperature distillation at the upper extended portion. This bidder of the proposal for change over of heating system the present owner of Aca A Engineering Services was instrumental in the above modification from the inception stage and tuned his activities in corresponding changes in the design of bottom shaft extension of water jacket vessel modification of grate stool grate ring etc. to take care of additional burden of deep coal bed more and consistent saturated air addition and distribution etc. till the development was Perfected. 4.1 IMPORTANT AND UNIQUE FEATURES AND FLEXIBILITIES OF OPERATION OF NEW GENERATION TECHNOLOGY OF EXTENDED SHAFT GASIFIER Flexibility in varying the generation of producer gas(PG) from the reactors to suit Reheating Furnace heat input requirements from time to time. The production of gas is controlled by variation in air input which can be instantly controlled by pressure controller as per heat demand. There is no necessity of bleeding the gas during normal operation with reduction in heat demand. Shut off possibility of the Reactor in case of any emergency shut down of the Kiln. In case of any emergency and short shut down the gasifier is kept under natural draft that is a very controlled amount of air is allowed to pass through the gasifier by natural convection and the bleeder is kept open. The product line is kept isolated from gasifier by water seal. The air-blower remains stopped during this period. From this condition the normal production can be quickly resumed by starting the air-blower and shutting off the bleeder. The B.S.T controller will automatically operate. The producer gas is taken into line by breaking the water seal. No necessity of Flare type arrangement to burn the PG generated after shutting off the coal and steam to the reactor. There is no necessity of flaring the gas during emergency shut down i.e during natural draft condition. The gas production is very low with natural convection air-flow and lower bed temperature. Moreover the CO content of the gas is minimal because the reaction CO2 + C = 2CO is endothermic and so as per La-chatelier principle this reaction will be very very low with only 2 to 3% CO in the stack gas which is immediately dispersed into atmosphere and will be below the flammability limit. The volatile matter content will also be very low due to lower bed temperature in the extended portion. Maintenace of same temperature profile in the operation of the Reheating Furnace with PG Plant. The temperature and flue gas quantity from PG firing being remained almost same as furnace oil firing the heat flux from flue gas to the charge will remain unaffected and so the operation of the kiln with PG firing in our opinion will not change. In various steel plants like Bokaro Bhilai etc. kilns are operated with gaseous fuels like blast furnace gas Coke-oven gas or combination etc. Purity of Gas The generated gas is fairly pure and consistent in quality. After the mixing cum washing chamber the dust particles and heavy tar particles of more than 40 microns are mostly removed. The dust particles after washing chamber will be hardly 150 mgms/Nm. The minimal tar vapour will be completely burnt out in the furnace and the flue gas will be tar free. So far as sulphur content is concerned most Indian coal around Mahanady Ranigunge area is containing about 0.3% sulphur by weight. The producer gas picks up less than 50% of sulphur of coal . On this basis the SO2 content in the flue gas with about 2% or more O2 will be hardly 30 to 40 ppm from the Data Bank of PCRA(Petroleum Conservation Research Association). The corresponding SO3 content from rough factor data of PCRA will be less than 5 ppm with a dew point of less than 50A A C ENGINEERING SERVICES ADVANTAGE OF INSTALLING NEW GENERATION PRODUCER GAS PLANTS Any grade of Indian Coal may be used for Gasification in Gas Plants designed by Engineering Services.The temperature of the Gas is 700C to 800C therefore maintenance cost will be negligible.No insulation is required in Gas Lines.No possibility of chocking in Gas Lines.Approx. 1.0 MT of Tar will be generated per day/ per Gasifier as by-product which is salable at approx. Rs.20000/- PMT or may be used as Furnace Oil. Cost of Producer Gas firing is 1/3rd the cost of Oil firing.The Pay-back period is below four months. The Calorific Value of Gas is 1350-1650 K Cal/NM3.The Flame Temperature may be attained upto 16000C.Engineering Services has developed various Models/Sizes i.e. 2.1 M Dia to 3.6 M Dia Producer Gas Plants depending upon the requirement of clients.Smooth Grate Rotating System by installing Ball Housing Thrust Bearing System.

Company Details

Focusing on a customer-centric approach ENGINEERING SERVICES has a pan-India presence and caters to a huge consumer base throughout the country. Get Industrial Gas Plants from ENGINEERING SERVICES at Trade India quality-assured services.

Business Type

Manufacturer, Service Provider, Supplier

Employee Count

40

Establishment

1984

Working Days

Monday To Sunday

Related Products

More Product From This seller

Seller Details

Howrah, West Bengal

Accepts only Domestic inquiries

Proprietor

Mr. Himachal Samanta

Address

13/12/1 Kankra Para Lane Howrah West Bengal 711104 India

Industrial Gas Plants in Howrah

Report incorrect details