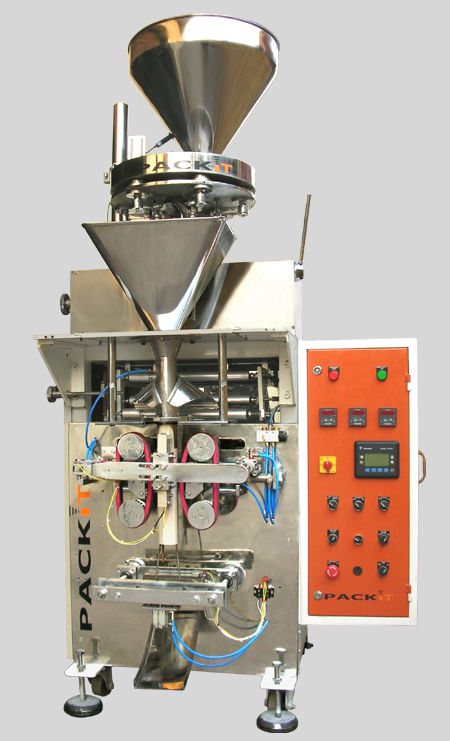

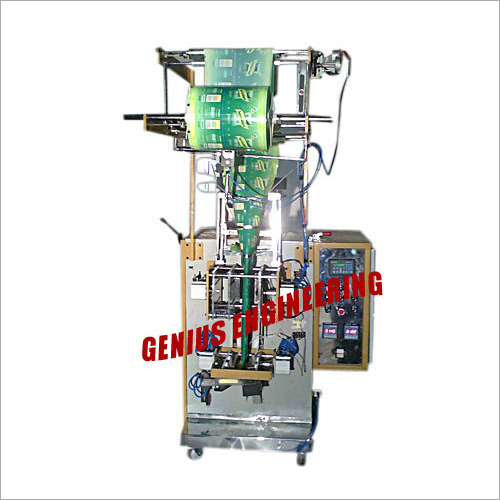

Pouch Making Machine - 300-1200mm Material Width, 30-500mm Bag Length | High Operational Fluency, Long Service Life, User-friendly Design

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Stainless steel |

| Dimensions | NA |

| Production speed | 150 bags/min |

| Bag length | 30-500 mm |

| Bag width | 150-500 mm |

| Material width | 300-1000 mm |

| Material diameter | 600 mm |

| Features | Long life, High fluency, User friendly, Low energy |

Product Overview

Key Features

As a competent organization, we are engaged in manufacturing, exporting and supplying supreme quality Pouch Making Machine. For the manufacturing of this machine, our technocrats use superior quality components and pioneering technology in sync with the defined international quality standards. It is used for production of stand-up pouch, zipper pouch, 3-side sealing bag, bottom gusseted stand-up pouch, combined stand-up/zipper pouch and many more. This Pouch Making Machine is offered to our respective clients at reasonable rates.

Features:

-

Long service life

-

High operational fluency

-

User friendly design

-

Low energy consumption

Main Mechanism

Main drive servo motor: The operator can change the feeding and sealing time for each material independently. Sealing temperature adjustment unnecessary while machine speed up. This mechanism can help to reduce the lost of material greatly.

Feeding servo motor*2: The pouch length is accurately controlled by servo motor includes middle pulling stand and rear pulling stand for upgrading production speed.

Outer transmission mechanism: Compared with inner transmission mechanism, the structure of brand-new outer transmission mechanism is much simple and ease to maintenance

The new FTSC-V pouch making machine can give about 30% more productivity than conventional bag making machines.

Pouch Making Machine Capability

One machine can produce various pouches such as three side sealing bag, stand up pouch, bottom gusseted stand up pouch, zipper pouch, combined stand up and zipper pouch.

3-side sealing bag: 3 lanes production and the skip seal function can reach 9 times of feeding length. (max.1,200mm).

Stand up pouch and zipper pouch: 2 lanes production.

Zipper / gusset inserting and zipper pouch sealing zone: The film enters into intermittent path from this zone. The zipper inserting tension is controlled by motor incorporated buffer roller unit in order to cope with the rush pulling that cause by intermittent path.

Optional Accessories

- Two functions unwind stand.

- Both side printed film adjusting device.

- Multiple punching devices.

- Product conveyer.

- Valve sealing device.

- Air chiller.

Technical Specifications

| Specifications | AP -450x500 Pouch Making Machine | AP-500x600 Pouch Making Machine |

| Material Width (mm) | 300 - 1,000 | 400 - 1,200 |

| Material Diameter (mm)(max.) | 600 | 600 |

| Bag Length (mm)(Max. 1,200mm skip-seal production) | 30-500 | 30-500 |

| Bag Width (mm)(Min. 75mm Multi-Lane Production) | 150-500 | 200-600 |

| Mechanical Speed (bags/min.) | 150 | 150 |

| Feeding Speed (m/min.) (max.) | 30 | 30 |

| Production Line | Three side sealing bag 1 4 Lanes | Three side sealing bag 1 - 4 Lanes |

| Stand up 1-2 / zipper pouch 1 4 Lanes | Stand up1-2 / zipper pouch 1 - 4Lanes | |

| Bottom gusseted pouch 1 lane | Bottom gusseted pouch 1 lane |

Company Details

We are manufacture all kind of Filling & Pouch Packaging Machine like Liquid Oil Shampoo Tomato ketchup spice Powder pharma powder Granules Liquor Paste Etc .

Business Type

Exporter, Manufacturer, Service Provider, Supplier, Trading Company, Wholesaler

Employee Count

14

Establishment

2010

Working Days

Monday To Saturday

GST NO

06AADCV2446H1ZE

Payment Mode

Cheque

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 06AADCV2446H1ZE

Faridabad, Haryana

Director

Mr Anil Kumar

Members since

4 Years

Address

Plot No. 57, Street No. 6E, Saroorpur Industrial Area, Sohna Road, Faridabad, Haryana, 121005, India

automatic pouch packing machines in Faridabad

Report incorrect details