Peanut Blanching Line

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Stainless Steel |

| Dimensions | Varied |

| Capacity | Customizable |

| Power | Electric |

| Weight | Depends On Model |

| Voltage | 220V/380V |

| Warranty | 1 Year |

| Features | High Efficiency, Low Maintenance, Easy Operation, Durable Design, Cost Effective, High Capacity, Clean Peanuts, Automated Process |

Product Overview

Key Features

Peanut Blanching Line

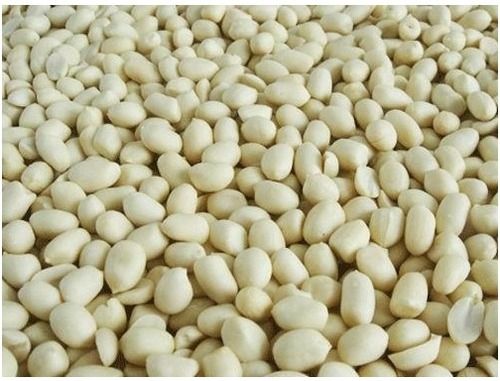

We have gained immense appreciation among our clients for manufacturing and exporting an excellent quality assortment of Peanut Blanching Line in the leading market. These blanching machines are used to clean, shell, sort and blanch numerous peanuts. Widely demanded in food industry, our Peanut Blanching Line range is well accredited among customers for its features like robust construction, high operational fluency and negligible maintenance cost. We are offering these blanching line machines to our clients at cost effective prices.

Further Details:

Peanut blanching and roasting can provide substantial value addition to the raw groundnuts.

is one of large peanuts country on planting & consumption & processing & export, in the past years, peanut manufacturers main export raw peanuts, with or without shell, such condition causes manufacturers enter low profit margin and face to high crisis on international business. Following the rising demand on many snacks manufacturers, confectionary within the country and oversea market, most of local peanut manufacturers begin to enter the further processing on peanuts, thus it is a good project.

Processing purpose

It begins from raw peanut in shell, through cleaning, shelling, grading, sorting, roasting, blanching and packing, peanuts will be ready for making coating, frying, salting, and peanut butter.

Process Flow Chart

Peanuts Cleaning & Shelling: Peanut in shell or pods are cleaned by destoner, the leaves, small stalks and stones will be separated by mechanical, then feed into peanut sheller, peanut kernels and shell will be separated automatically.

Peanuts Grading & Sorting: According to different size and count, peanut kernels will be graded by peanut sieving machine, then they are flowing to different conveyors for sorting out the unperfected by manual, if considering the manpower cost, such conveyors can be replaced by color sorter.

Peanuts Roasting: Low temperature roasting is preferable in this processing, in order to ensure the blanching result and reduce the split ratio during blanching. The suitable thickness of peanuts should be 1

Peanuts Blanching: Light roasted peanuts come from vibrating discharge device, through bucket conveyor, are feed into blancher, under the rotating and friction of rollers, the red skin will be taken, and sucked by the air cyclone. The blanched peanuts will fall down to the conveyor.

Blanched Peanut Packing: packing is done as per customer specification, generally they are packed in 10 or 12.5 kgs vacuum polythene bags

Company Details

Business Type

Exporter, Manufacturer, Supplier

Employee Count

100

Establishment

1976

Working Days

Monday To Saturday

Payment Mode

Telegraphic Transfer (T/T)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Jimo, Shandong

Sales Manager

Mr Sun Gongxin

Address

No. 916, Qingwei Road Jimo, Shandong, 266200, China

blanched peanut in Jimo

Report incorrect details