Steel Alloy Peanut Frying Line

Price:

Get Latest Price

In Stock

Product Specifications

| Capacity | 500kg/hr |

| Material | Stainless steel |

| Power | 3-phase |

| Dimensions | Variable |

| Weight | Heavy duty |

| Usage | Peanut frying and processing |

| Compliance | CE |

| Features | Automated process, High capacity, Continuous operation, Easy operation, High efficiency, Consistent quality, Improved yields |

Product Overview

Key Features

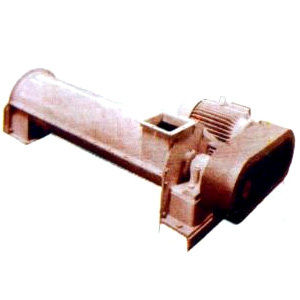

Peanut Frying Line

Manufactured to perfection, we are one of the leading manufacturers and exporters of Peanut Frying Line. By strictly adhering to the industry quality standards, we are manufacturing entire assortment of frying line machine using high grade raw materials & components. These frying line machines find huge usage in several snack manufacturing company. Peanut Frying Line, which we are offering in the market, is highly accredited by customers for its salient features like sturdy structure, high operational fluency and unmatched performance.

Further Details:

Simple Introduction

Simple flow chart: Roasting-cooling-blanching-frying-oil removing-flavor adding -cooling-metal detecting-packing

Roasting: In this line we match an automatic continuous roaster with multi-layers, the hot air is supplied by hot furnace, which burns wood and coal. The raw peanuts will be baked in low temperature (around 120-140 oC), the baking time is about 20-25 minutes, the moisture content will be reduced to suitable degree for following blanching.

Cooling: Due to the function of high pressure air fan, heat and humidity will bring quickly. The peanuts are ready to be blanched and fall to temporary bin.

Blanching: Light roasted peanuts are feed into blanchers, under the rotating and friction of rollers, the red skin will be taken, collected by the air cyclone. The blanched peanuts will fall down to the selecting conveyors.

Sorting: In order to make the blanched peanuts reach to export grade, we often match color sorter to pick out the imperfect peanuts. This sorting job can be done by manual, it depends on customers request.

Frying: In this line we use batch fryers, the temperature will be fixed between 150

Oil removing: The two fryers will work alternately, fried peanuts will be dumped into oil removing machine, under the function of centrifugal rotating of drum, the extra oil on peanut surface will leak out via the bottom outlet.

Flavor adding: the deoiling peanuts will be lifted to the flavor added drum, customer can add salt, powder type spices as their ingredients. The spices will be mixed with the fried peanut evenly.

Cooling: the flavor added peanuts will lie down to the mesh stainless steel conveyor for further cooling and ready to be packed.

Metal detecting: for final detecting in order to avoid any metal impurities will content in the fried peanuts.

Packing: In order to extend the shelf time of fried peanuts, most of customer will adopt vacuum package, or they will add deoxidizer in the bag. The package materials often use BOPP/PE compound film.

Electrical control system: in order to control the line operation simply, we design and match different element control parts on different section.

Company Details

Business Type

Exporter, Manufacturer, Supplier

Employee Count

100

Establishment

1976

Working Days

Monday To Saturday

Payment Mode

Telegraphic Transfer (T/T)

Related Products

More Product From This seller

Seller Details

Jimo, Shandong

Sales Manager

Mr Sun Gongxin

Address

No. 916, Qingwei Road Jimo, Shandong, 266200, China

Processing Machines & Equipment in Jimo

Report incorrect details