On Line Zinc Spray Systems Tube Mill

Price: 1121000.00 INR / Set

(950000.00 INR + 18% GST)

Get Latest Price

MRP:

1150000.00 INR / Piece

Weight :

1400.00 Kilogram

1 Pack Contains :

1

Minimum Pack Size :

1

In Stock

Product Specifications

| Production Capacity | 700-800/Shift |

| Cylinder Size | 305-350Mm X 620-730Mm |

| Spray Gun Type | Arc/Wire Flame |

| Blower Capacity | 3000 Cfm |

| Dust Collector Type | Fabric Bag |

| Conveyor Type | Twin Roller |

| Material | Steel |

| Features | Zinc Coating, High Output, Lpg Cylinder, Dry Spray, Roller Conveyor, Dust Collector, Semi-Automatic, Efficient, Durable, Safe |

| Product Type | Milling Machine |

| Payment Terms | Letter of Credit (L/C), Others, Telegraphic Transfer (T/T), Cheque |

| Supply Ability | 3 Per Month |

| Main Domestic Market | All India |

| Product Unit | 1 Piece/Pieces |

| Stock Quantity | 5 |

| GSTIN | 18% |

| Unit Type | Piece/Pieces |

| Pkg Box Length | 8.00 in |

| Min Quantity | 1 |

| Brand Name | METAL COAT Dry Spray Booth for LPG Cylinders |

| Shipping Type | order_percent |

| Price Type | fixed |

| Shipping Rate | 3.00 |

| Pkg Box Breadth | 35.00 in |

| Mop | 1 |

| Weight | 1400.00 Kilogram |

| Price | 950000.00 INR (Approx.) |

| MRP | 1150000.00 INR |

| Returnable | No |

| Packsize | 1 |

| Moq | 1 |

| Max Quantity | 10 |

| Currency | INR |

| Pkg Box Height | 15.00 in |

| Minimum Ordered Packs | 1 |

| Minimum Order Quantity | 1 |

Product Overview

Key Features

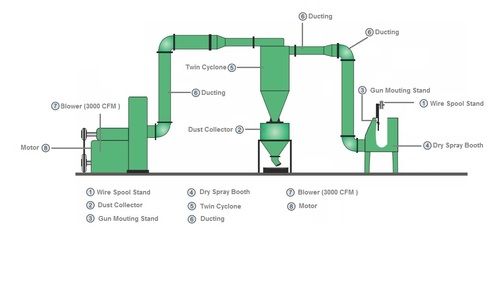

Type Of Thermal Spraying : Arc Spray

Dry Spray Booth With Roller Conveyor For Zinc Metallizing Of LPG Cylinders

Semi-Automatic Dry Spray Booth for Zinc Metallizing of external surface of LPG cylinder.

Purpose:

For Zinc Metallizing of external surface of LPG Cylinders Minimum diameter 305mm x 620mm length & maximum diameter 350mm x 730mm length Production Output:

700 to 800 nos. per shift cylinder diameter 305mm x 620mm length with Arc Spray Gun.

Brief Working:

The Cylinder is placed manually on twin roller conveyor which moves forward in longitudinal direction as well as rotates inside the dry spray booth. The twin roller conveyor is driven by electric motor. The Operator spray Zinc with the help of either Wire Flame Spray Gun or Arc Spray Gun (Air Drive or DC Drive) with Power Source.

The dust and fume created during Zinc Metallizing process is sucked by the exhaust fan mounted on Fabric Dust Collector. The Cyclone collect the coarse dust and very fine dust get collected in the Fabric Bag Dust Collector, keeping the environment clean and friendly.

Company Details

We, at Metal Coat started our journey way back in 1988, are one of the leading manufacturers and suppliers of a vast array of Thermal Spray Equipment and Coating Systems. With our wide range of Metallizing Equipment, Auxiliary Equipment, Consumables- we provide the right choice for your specific application. To manufacture these offered products in compliance with the set industry standards, our experienced professionals use the most modern machines and tools available. Our products are appreciated for their features such as corrosion resistance, efficient performance and flawlessness. Quality for us is one of the most important areas and we strongly believe that our consistent relationship with our customers purely depend on our capability to ensure delivery of good quality merchandise, every time keeping this in mind, we have ensured that our quality team is involved in all aspects of a product development and execution. Our offered products are widely demanded in automobiles, aerospace, textile, biomedical, paper, electrical, power generation, decorative, food processing, marine, oil, transportation, LPG Cylinder Manufacturing, Tube Mill, Railway and many more industries. Since thermal spraying is a dynamic industry, new customer requirements are continually arising. We take great pride in our company performance and ability to adapt to changing industry demands, consistently providing top quality products exceeding customer expectations. To perform our business processes in the best possible way, we have various departments like Design, Production, Testing, Quality Control. Apart from this, our ethical business practices, customization facilities, timely delivery, affordable prices have made us popular among our clients. Our huge base of clientele includes Multinational Companies, Big Engineering Companies, LPG Cylinder Manufacturers, Capacitor Industries and Government Organization like Defence and Indian Railways. We serve a wide variety of customers including multinational organizations, companies of diverse business operations and small and medium enterprises and business. Our services are aimed to provide apt solutions with enhanced technical assistance, enriched service offerings and empowered business operations.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

50

Establishment

1988

Working Days

Monday To Sunday

GST NO

08ACOPN0072D1ZQ

Payment Mode

Telegraphic Transfer (T/T)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 08ACOPN0072D1ZQ

Jodhpur, Rajasthan

Founder

Mr Mahesh Nagar

Address

B-43/44/45/46, Industrial Estate, Jodhpur, Rajasthan, 342003, India

tube mill machine in Jodhpur

Report incorrect details