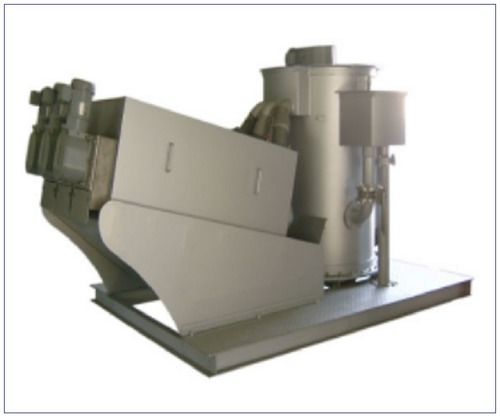

Manure Slurry Dewatering Machine - Carbon Steel & Stainless Steel, 1500x800x2000 Mm Dimensions, 7 Kw Electric Drive, Solid-liquid Separation With Screw Extrusion Technology

Price: 1000 USD

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Feature | The raw sewage was sent to the machine with a slurry pump, and the solid material was squeezed and separated through a screw shaft installed in the screen. The liquid was discharged from the liquid outlet through the screen. |

| Power Consumption | 7 Kilowatt (kW) |

| Material | carbon steel, stainless steel |

| Drive Type | Electric |

| Payment Terms | Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T) |

| Supply Ability | 100 Per Year |

| Delivery Time | 15 Days |

| Sample Policy | Contact us for information regarding our sample policy |

| Main Export Market(s) | Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa |

| Main Domestic Market | All India |

Product Overview

Key Features

Working principle :

The raw sewage was sent to the machine with a slurry pump, and the solid material was squeezed and separated through a screw shaft installed in the screen. The liquid was discharged from the liquid outlet through the screen.

Product model :

Model : ECOY200, ECOY280, ECOY300

Total poweri KWi : 7.0, 8.5, 8.5/10.5

Voltage (V, HZ) : 380/50, 380/50, 380/50

Length(mm) : 1500, 1500, 1500

Width(mm) : 800, 800, 800

Height(mm) : 2000, 2250, 2300

Weighti kgi : 550, 680, 680

Inlet diameteri mmi : 76, 76, 76

Waste water outlet diameter after separation (mm) : 108, 108, 108

Overflow Outlet diameter (mm) : 76, 76, 76

Diameter of screeni mmi : 200, 280, 300

Screen precision : 0.25mm, 0.5mm, 0.75mm, 1.0mm

Processing capacity (liquid (solids content <50%), m3/h) : 8-10, 10-15, 15-25

Remarks :

There is a difference of 2-5 cubic meters in the processing capacity of the solid material according to the viscosity and dryness of the material.

Company Details

Business Type

Exporter, Manufacturer

Employee Count

50

Establishment

2008

Working Days

Monday To Friday

Payment Mode

Telegraphic Transfer (T/T)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Chengdu, Sichuan

Sales Engineer

Mrs Judy Liu

Address

No.10,Jiuxing Avenue,High-tech Zone Chengdu, Sichuan, 610041, China

dewatering machine in Chengdu

Report incorrect details