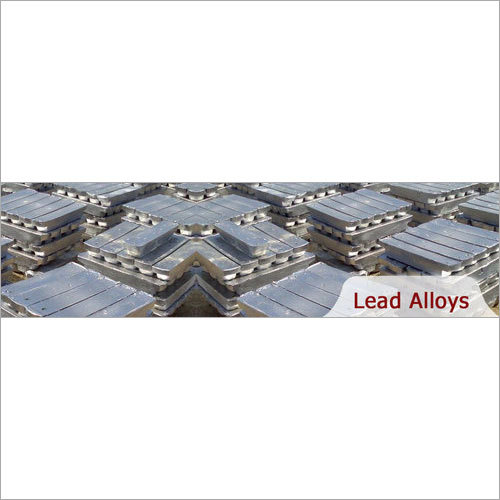

Lead Refining/alloying

Price:

Get Latest Price

In Stock

Product Specifications

| Process Type | Refining/Alloying |

| Material Processed | Lead |

| Impurity Removal | Yes |

| Throughput | Variable |

| Power | 220V |

| Dimensions | Customizable |

| Usage | Refining lead from secondary sources like battery scrap, removing impurities like copper, antimony, and other traces, resulting in high-purity refined lead suitable for various applications |

| Features | Lead refining, Impurity removal, High purity, Alloying, Efficient process |

Product Overview

Key Features

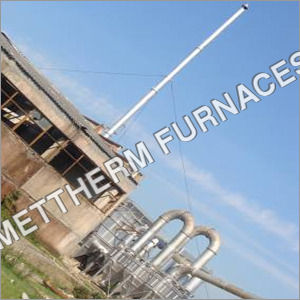

LEAD REFINING PROCESS

The lead received from Rotary Furnace is called hard lead /crude lead .The lead tapped from the furnace has to be cleaned from residual oxides and slag. After stirring for a while the impurities settle at the surface and are skimmed off .

Crude lead originating from battery scrap is normally alloyed with copper andantimony and also some traces of Ca, Sn, As, Zn. In order to remove the unwanted elementsBy adding sulphur to the lead melt and after stirring for some time, a Pb/Cu2S-dross (and if present with minor parts of Zn, Sb, As) is formed and skimmed off.

This de- copperisation step should be carried out at least two times or more to secure the refining result.The de-copperised lead still contains a large amount of antimony (and maybe some Sn, As). All of these elements can be removed by oxidation. For that purpose air or oxygen-enriched air is blown into the melt and stirred. The different oxides formed settle at the surface and can be skimmed off. The oxidizing process is completed when mainly lead oxide is formed. Instead of oxidizing the impurities by injecting air, sodium nitrate (NaNO3) can be added. Here again a dross containing the impurities (and lead) is formed, which is skimmed off after wards. All refining by-produced or residues should be processed to recover lead and other valuables components.

The refining processes and the purity of the refined lead are monitored by chemical analysis.

Company Details

Business Type

Exporter, Manufacturer, Service Provider, Supplier

Employee Count

20

Establishment

2006

Working Days

Monday To Sunday

GST NO

06AGEPB3375R1Z3

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 06AGEPB3375R1Z3

Faridabad, Haryana

Proprietor

Mr. Dinesh Batra

Members since

2 Years

Address

Plot No-4, Gali No-1, Bajri Industrial Area, Badkhal Pali Road, Faridabad, Haryana, 121009, India

lead alloys in Faridabad

Report incorrect details