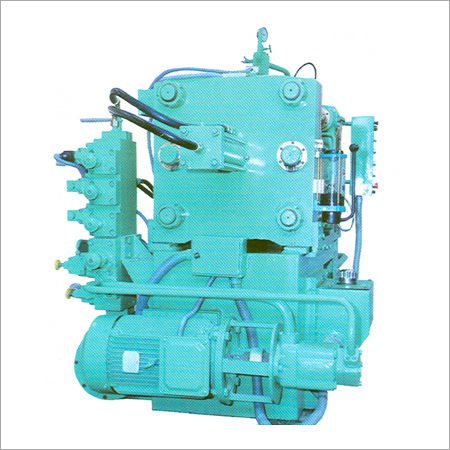

High Pressure Die Casting Machine - Precision Engineering For Brass, Aluminium, Zinc & Tin Alloys | Features: Hydraulic Mono Block, Centralized Lubrication, Three Stage Injection Adjustment

Price:

Get Latest Price

In Stock

Product Specifications

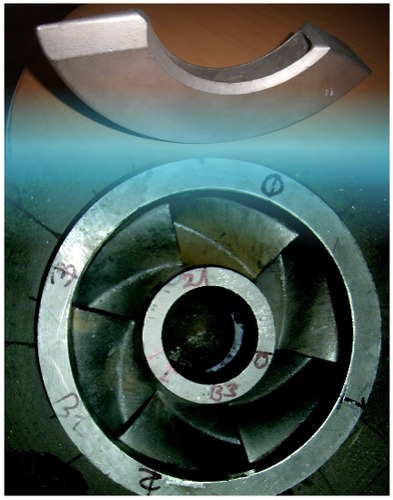

| Material | Cast Iron |

| Diameter | Variable |

| Weight | Variable |

| Blades | Multiple |

| Finish | Uncoated |

| Mounting | Flange |

| Tolerance | High Precision |

| Features | High Efficiency, Durable Design, Long Lifespan, Low Power Use, Easy Operation, Customizable, Standard Options |

Product Overview

Key Features

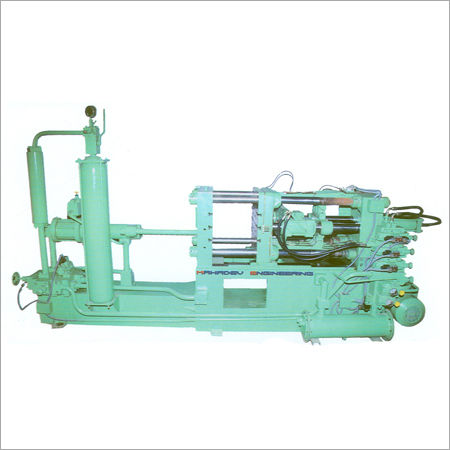

Our production staffs manufacture these High Pressure Die Casting Machine using latest tools and technologies in our advanced unit. Further, we make sure that these are made in compliance with the industry standards and norms. Our clients can avail these Die Casting machines at competitive prices from us.

All hydraulic valves are mounted on Hydraulic blocks to eliminate Cumbersome Hydraulic piping. Hydraulic equipment of renounced Yuken India/Vicker India Ltd.

Operation

Machines manufactured by us are ideally suitable for Brass, Aluminium, Zinc, and Tin alloys, Depending upon the gate geometry, the machine can be adjusted for centre and bottom feeding with out tempering with any of the hydraulic fittings

Salient Features

- Three stage injection

- Centre and bottom injection adjustment-through telescopic cylinders

- Centralized lubrication

- Simple hydraulic system

- Heat exchanger incorporated in return low

- Hand and semi-auto-cycle operation

- Built in provision for core cylinders

- Provision for zero leakage of Nitrogen gas

Optional Accessories

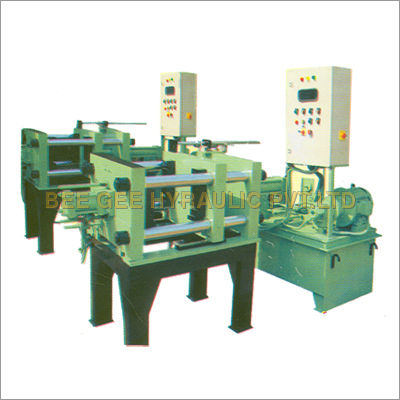

- Programmable logic control(PLC) panel

- Die stroke adjustment

- Shutter for safety

- Auto extractor/Auto knockout

- Auto spray

Technical Specifications

| Model |

| MDE-80 | MDE-120 | MDE-180 | MDE-250 | MDE-400 |

|---|---|---|---|---|---|---|

| Locking Force | Tonnes | 80 | 120 | 180 | 250 | 400 |

| Injection force with intensifier | Tonnes | 11.5 | 13 | 23 | 38 | 45 |

| Hydraulic Ejection Force | Tonnes | 4 | 6 | 10 | 15 | 22 |

| Die Mounted Plated(hxv) | mm | 520x520 | 650x650 | 760x740 | 810x860 | 950x980 |

| Space between tie bars(hxv) | mm | 330x330 | 428x428 | 470x510 | 510x590 | 600x660 |

| Max. Die Height | mm | 400 | 450 | 600 | 750 | 750 |

| Min. Die Height | mm | 200 | 200 | 200 | 250 | 250 |

| Tie Bar Diameter | mm | 60 | 70 | 80 | 100 | 125 |

| Die opening stroke | mm | 200 | 300 | 450 | 500 | 600 |

| Injection Stroke | mm | 250 | 275 | 300 | 350 | 400 |

| Ejection stroke | mm | 50 | 75 | 100 | 100 | 145 |

| Distance between centre and bottom injection | mm | 85 | 120 | 150 | 150 | 190 |

| Electric Motor capacity | kw | 7.5 | 15 | 18.5 | 22.4 | 22.4 |

| Working pressure | Kg/min | 70 | 100/25 | 100/35 | 150/35 | 150/35 |

| Capacity of Oil tank | litres | 300 | 450 | 500 | 600 | 700 |

| Machine weight | Tonnes | 3.5 | 4.5 | 8.0 | 12.5 | 15.0 |

| Shot capacity(max. Injection weight) | GMS | 1000 | 1800 | 3200 | 3710 | 7000 |

Company Details

Focusing on a customer-centric approach, MAHADEV DIE CASTING MACHINES & ENGG WORKS has a pan-India presence and caters to a huge consumer base throughout the country. Buy Machineries in bulk from MAHADEV DIE CASTING MACHINES & ENGG WORKS at Trade India quality-assured products.

Business Type

Manufacturer, Supplier

Employee Count

20

Establishment

2018

Working Days

Monday To Sunday

GST NO

07AFFPD6861G1ZI

Payment Mode

Cash Against Delivery (CAD), Cash Advance (CA)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 07AFFPD6861G1ZI

Delhi, Delhi

Sales Manager

Mr. Vishal Dabas

Address

PLOT NO. 843, LAL DORA EXTENSION, KANJHAWALA, Delhi, Delhi, 110081, India

high pressure die casting in Delhi

Report incorrect details