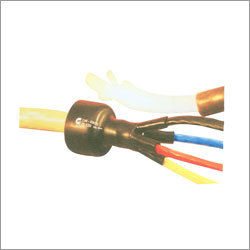

Heat Shrink Low Voltage Cable Breakout

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Polyolefin |

| Tensile Strength | 12 N/mm2 |

| Elongation | 350% |

| Density | 1.05 gm/cm3 |

| Hardness | 45 Shore D |

| Shrink Temp | 125oC |

| Dielectric Strength | 12 KV/mm |

| Features | Strong seal, UV resistant, Weatherproof, Safe, Reliable, Durable, Insulation, Moisture proof |

Product Overview

Key Features

We are the prominent organization,

having proper knowledge of the domain and, actively engaged in manufacturing and

supplying an extensive gamut of Heat Shrink

Low Voltage Cable Breakout. The entire range of product is designed using

superior quality material, sourced from the authentic vendor of the market. We

offer this Heat Shrink Low Voltage Cable

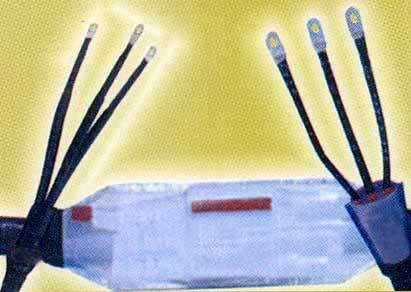

Breakoutin different sizes and shapes. It is used in electric power industry for providing

insulation, binding force and sealing over the crutch of multi core cables at

branching point.

Features:

- UV resistant

- Withstand adverse weather

conditions - Safe to use

Heat Shrink Low Voltage Cable Breakout

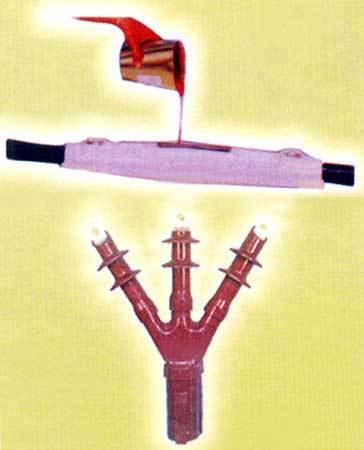

Heat Shrink Low Voltage Cable Breakouts provide a strong and permanent environmental seal to the crutch of 2, 3, 4, 5, & 6 core PVC, XLPE Rubber and PILC cables upto 1.1 KV rated voltage.

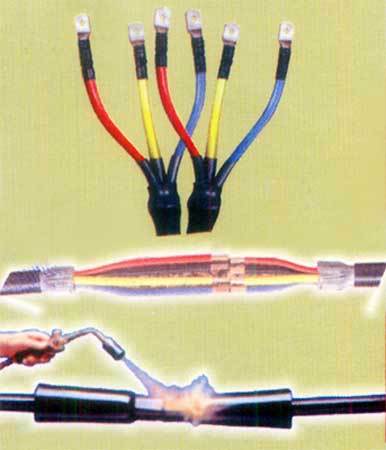

The breakouts are manufactured form high quality cross linked polyolefin material that offer an exceptional insulation and long term service reliability.

The Breakouts are internally coated with hot melt adhesive. These breakouts when installed in position provide 100% water/moisture proofness to the system.

Technical Specification

| Properties | Value | Standard |

| Physical | ||

| Tensile Strength | 12 N/mm2 (Mpa) (min.) | ASTM D638 |

| Ultimate Elongation | 350% (min) | ASTM D638 |

| Density | 1.05+0.2 gm/cm3 | ASTM D792 |

| Hardness | 45+10 Shore D | ASTM D2240 |

| Water absorption | 0.2 (max.) | ASTM D570 |

| Thermal | ||

| Accelerated ageing | (120oC for 500 hrs) | ASTM D2671 |

| Tensile Strength | 11 N/mm2 (Mpa) (min.) | ASTM D638 |

| Ultimate Elongation | 300% (min.) | ASTM D638 |

| Low Temperature Flexibility (-40oC for 4 hrs.) | No Cracking | ASTM D2671 |

| Heat Shock (250oC for 30 min.) | No Cracking or flowing | ESI 09-11 |

| Shrink Temperature | 125oC | IEC 216 |

| Continuous Temperature Limit | -40 to +100oC | IEC 216 |

| Electrical | ||

| Dielectric Strength | 12 KV/mm. (min) | ASTM D149 |

| Volume Resistivity | 1 x 1014Ohm.cm (min) | ASTM D257 |

| Dielectric constant | 5 (max.) | ASTM D150 |

Selection Chart

All dimension are in mm

| Code No. | No. of Core | Ds | d | L | I | Tb | Tc | ||||

| Ds | Df | ds | df | Ls | Lf | Is | If | f+10% | f+10% | ||

| LV2PEBB-0308S | 2 | 22 | 8 | 10 | 3 | 70 | 85 | 14 | 20 | 2.2 | 2.0 |

| LV2PEBB-0308* | 2 | 32 | 8 | 14 | 3 | 70 | 85 | 15 | 20 | 2.2 | 2.0 |

| LV2PEBB-0410 | 2 | 32 | 10 | 14 | 4 | 70 | 85 | 15 | 20 | 2.2 | 2.0 |

| LV2PEBB-0410A | 2 | 42 | 11 | 14 | 4 | 65 | 85 | 14 | 20 | 2.2 | 2.0 |

| LV2PEBB-0720* | 2 | 60 | 20 | 24 | 7 | 95 | 120 | 25 | 34 | 3.0 | 2.5 |

| LV2PEBB-1565* | 2 | 110 | 65 | 45 | 15 | 100 | 140 | 40 | 60 | 2.2 | 2.0 |

| LV2PEBB-1565A* | 2 | 156 | 65 | 50 | 15 | 100 | 140 | 40 | 60 | 2.2 | 2.0 |

| LV3PEBB-0413 | 3 | 37 | 14 | 15 | 4 | 80 | 100 | 15 | 21 | 2.2 | 2.0 |

| LV3PEBB-0820 | 3 | 53 | 20 | 25 | 8 | 160 | 188 | 55 | 62 | 3.7 | 2.8 |

| LV3PEBB-1330 | 3 | 80 | 30 | 36 | 13 | 185 | 215 | 60 | 75 | 3.9 | 3.1 |

| LV3PEBB-1330A* | 3 | 95 | 30 | 39 | 13 | 185 | 215 | 60 | 75 | 3.9 | 3.1 |

| LV3PEBB-2145 | 3 | 110 | 45 | 55 | 20 | 200 | 235 | 70 | 88 | 4.3 | 3.0 |

| LV3PEBB-2145A* | 125 | 45 | 60 | 21 | 190 | 230 | 65 | 90 | 4.6 | 3.4 | |

| LV3PEBB-2755 | 3 | 140 | 56 | 70 | 28 | 215 | 250 | 80 | 90 | 4.6 | 3.4 |

| LV3PEBB-2755A* | 3 | 180 | 58 | 70 | 29 | 200 | 250 | 75 | 90 | 4.6 | 3.4 |

| LV4PEBB-0312* | 4 | 40 | 12 | 14 | 3 | 80 | 100 | 15 | 25 | 2.4 | 1.7 |

| LV4PEBB-0415 | 4 | 41 | 16 | 14 | 4 | 80 | 100 | 15 | 23 | 2.4 | 1.7 |

| LV4PEBB-0415A | 4 | 50 | 17 | 17 | 4 | 75 | 95 | 15 | 23 | 2.4 | 1.7 |

| LV4PEBB-0821 | 4 | 58 | 26 | 21 | 7 | 140 | 170 | 32 | 48 | 3.5 | 2.5 |

| LV4PEBB-0825 | 4 | 70 | 28 | 25 | 8 | 130 | 165 | 32 | 46 | 3.5 | 2.5 |

| LV4PEBB-0925 | 4 | 70 | 30 | 25 | 9 | 155 | 190 | 35 | 48 | 3.7 | 2.6 |

| LV4PEBB-1130* | 4 | 80 | 31 | 31 | 10 | 150 | 190 | 32 | 47 | 3.7 | 2.6 |

| LV4PEBB-1334 | 4 | 90 | 42 | 35 | 13 | 170 | 210 | 40 | 52 | 3.7 | 2.6 |

| LV4PEBB-1334A* | 4 | 100 | 44 | 35 | 13 | 170 | 208 | 40 | 51 | 3.7 | 2.6 |

| LV4PEBB-2454 | 4 | 125 | 44 | 40 | 14 | 175 | 208 | 40 | 51 | 3.7 | 2.6 |

| LV5PEBB-0415* | 5 | 50 | 16 | 15 | 4 | 85 | 110 | 23 | 33 | 3.2 | 2.6 |

| LV5PEBB-0415A* | 5 | 57 | 17 | 15 | 4 | 75 | 110 | 23 | 33 | 3.2 | 2.6 |

| LV5PEBB-0832* | 5 | 80 | 32 | 26 | 8 | 155 | 190 | 55 | 65 | 3.3 | 2.8 |

| LV5PEBB-0832A* | 5 | 100 | 33 | 32 | 8 | 150 | 190 | 50 | 65 | 3.3 | 2.8 |

| LV6PEBB-0737* | 6 | 85 | 37 | 23 | 7 | 100 | 140 | 30 | 46 | 3.2 | 2.6 |

Company Details

Focusing on a customer-centric approach, POWERTECH ENGINEERS has a pan-India presence and caters to a huge consumer base throughout the country. Buy Insulation Material in bulk from POWERTECH ENGINEERS at Trade India quality-assured products.

Business Type

Manufacturer, Supplier

Employee Count

50

Establishment

2002

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Ambala, Haryana

Accepts only Domestic inquiries

Proprietor

Mr. Rajesh Sharma

Address

Plot No. 60, Kailash Nagar, Model Town, Ambala, Haryana, 134003, India

cable breakouts in Ambala

Report incorrect details