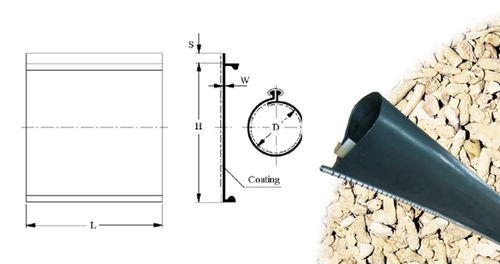

Heat Shrink Breakout - Cross-linked Polyolefin, Multi-core Design For Optimal Insulation And Protection

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Polyolefin |

| Colors | Black, Red |

| Sizes | Varied |

| Temperature range | -45 to 105°C |

| Shrink temperature | 110-135°C |

| Tensile strength | 10-12 MPa |

| Elongation | 230-300% |

| Features | Sealing defense, Multi-core wires, Varied patterns, Durable material, Temperature resistant, Easy installation, Cost effective |

Product Overview

Key Features

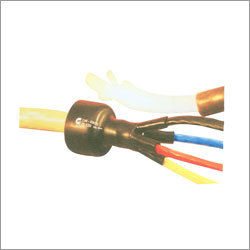

Heat Shrink Breakout

It offers sealing defense over multi-core wire crutch, our offered Heat Shrink Breakout is valued among our end users due to its outstanding qualities. We produce this breakout with the assistance of the premium quality cross linked polyolefin that we obtained from the authentic dealers and the internal layer is covered with bonding agents. We make sure our end users that this breakout is accurately audited on diverse parameters by our specialists at our sound operational testing division. Bearing in mind end users several requirements, we offer this Heat Shrink Breakout in varied specifications.

Key Features are listed as below:

- It is fabricated using cross connected polyolefin, internal coated with bonding agent at the ends

- It offer fastening safeguard over multi-core wire crutch, together with 2-, 3-, 4-, 5-cores breakout

- Able to meet the varied pattern needs

- Incessant operation temperature ranging from -45 to 105

- The Shrink temperature which initiates at 110, and completely recovered at 135

| Technical Data: | |||||||

| Property | Test Method | Standard Value | |||||

| Insulated Breakout | Oil Resistant Breakout | Conductive Breakout | |||||

| Operation Temperature | IEC 216 | -45 to 105 | -45 to 105 | -45to 105 | |||

| Tensile Strength | ASTM-D-2671 | 12MPa | 11MPa | 12MPa | |||

| Elongation at Break (120,168 hrs) | ASTM-D-2671 | 300% | 300% | 300% | |||

| Tensile Strength after Aging (120,168 hrs) | ASTM-D-2671 | 10MPa | 9MPa | 10MPa | |||

| Elongation at Break after Aging | ASTM-D-2671 | 230% | 230% | 230% | |||

| Tensile Strength after Dipping | ASTM-D-2671 | 0 | 10MPa | 0 | |||

| Elongation at Break after Dipping | ASTM-D-2671 | 0 | 230% | 0 | |||

| Dielectric Strength | IEC 60243 | 20kV/mm | 20kV/mm | 0 | |||

| Water Absorption | ISO 62 | 0.5% | 0.5% | 0.5% | |||

| Volume Resistivity | IEC 60093 | 1014.cm | 1014.cm | 102~104cm | |||

| Selection Table: | |||||||

| Product No. | Base Diameter | Finger Diameter | Full Length (10%)/mm | Finger Length (10%)/mm | |||

| As Supplied (Min) /mm | After Recovered(Max) /mm | As Supplied(Min) /mm | After Recovered (Max) /mm | ||||

| 2 cores | WRSZT2-24/120# | 24 | 12 | 12 | 5 | 130 | 55 |

| WRSZT2-38/161# | 38 | 16 | 20 | 7 | 140 | 60 | |

| WRSZT2-48/182# | 48 | 18 | 25 | 9 | 145 | 60 | |

| WRSZT2-60/243# | 60 | 24 | 35 | 11 | 135 | 55 | |

| WRSZT2-72/254# | 72 | 25 | 40 | 12 | 140 | 60 | |

| 3 cores | WRSZT3-24/16-2# | 24 | 16 | 11 | 5 | 140 | 50 |

| WRSZT3-48/22-1# | 48 | 22 | 18 | 7 | 170 | 55 | |

| WRSZT3-60/280# | 60 | 28 | 25 | 8 | 175 | 55 | |

| WRSZT3-70/361#* | 70 | 36 | 30 | 13 | 210 | 55 | |

| WRSZT3-85/452#* | 85 | 45 | 40 | 16 | 225 | 60 | |

| WRSZT3-110/533#* | 110 | 53 | 42 | 19 | 250 | 85 | |

| WRSZT3-125/634#* | 125 | 63 | 58 | 25 | 245 | 95 | |

| WRSZT3-140/635# | 140 | 63 | 65 | 25 | 245 | 90 | |

| 4 cores | WRSZT4-38/180# | 38 | 18 | 10 | 5 | 130 | 45 |

| WRSZT4-50/241# | 50 | 24 | 16 | 7 | 135 | 45 | |

| WRSZT4-70/322# | 70 | 32 | 23 | 9 | 180 | 65 | |

| WRSZT4-80/443# | 80 | 44 | 30 | 13 | 210 | 75 | |

| WRSZT4-90/444# | 90 | 44 | 35 | 13 | 210 | 75 | |

| WRSZT4-110/535# | 110 | 53 | 40 | 13 | 210 | 75 | |

| WRSZT4-110/515# lengthen | 110 | 51 | 40 | 17 | 225 | 55 | |

| 5 cores | WRSZT5-42/210# | 42 | 21 | 12 | 5 | 155 | 55 |

| WRSZT5-57/291# | 57 | 29 | 16 | 7 | 170 | 60 | |

| WRSZT5-70/382# | 70 | 38 | 23 | 9 | 170 | 55 | |

| WRSZT5-90/503# | 90 | 50 | 30 | 13 | 180 | 60 | |

| WRSZT5-120/474# | 120 | 47 | 39 | 14 | 205 | 80 | |

Company Details

Focusing on a customer-centric approach, J. M. ENGINEERING CO. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Insulation Material in bulk from J. M. ENGINEERING CO. at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier, Trading Company

Employee Count

10

Establishment

1985

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Mumbai, Maharashtra

Proprietor

Mr. Kamlesh K. Sheth

Address

177, Manhar Building, 3rd Floor, Lohar Chawl, Mumbai, Maharashtra, 400002, India

cable breakouts in Mumbai

Report incorrect details