Heading Machine - High Speed Automatic Steel & Brass Processing | Mobile Design With Dual Heading Punches, Low Vibration Operation, High Mass Production Efficiency

Price:

Get Latest Price

In Stock

Product Specifications

| Product Type | Heading Machine |

| Dominant Color | Orange |

| Material | Steel, Bronze |

| Power | Electric |

| Capacity | Variable |

| Dimensions | Large |

| Speed | High |

| Usage | Manufacturing screws, rivets, and auto parts from steel, brass, aluminum. |

| Features | High Speed, Automatic, High Production, Easy Operation, Low Vibration, Cost Saving |

Product Overview

Key Features

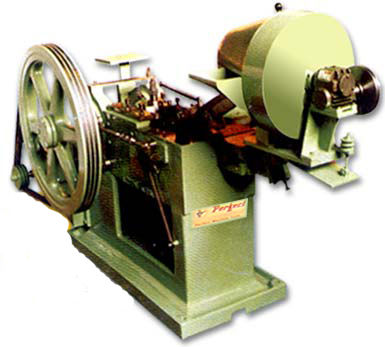

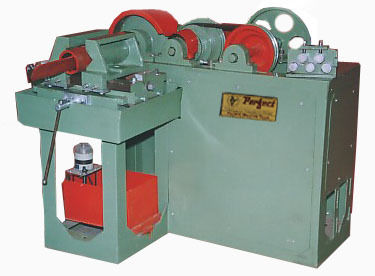

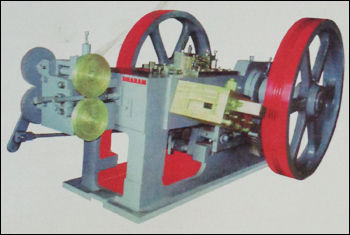

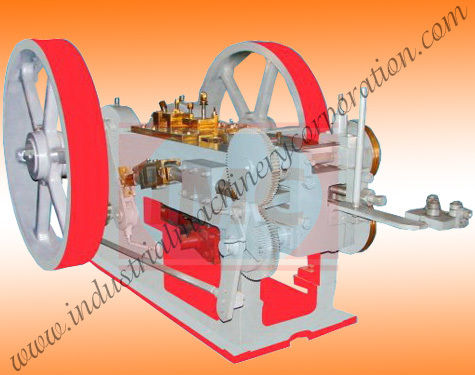

Perfect Automatic High Speed Heading Machine is specially designed for high speed, fully automatic, high mass production for a wide variety of screws, machine screws, steel screws, micro screws, rivets, micro rivets, cycle and automobile parts and other similar components made of steel, brass, aluminum, etc.

The design of heading slide is particularly mobile and carries two heading punches, one for straightening and other for finishing. Straightening and finishing punches as well as dies can be accurately adjusted to easily accessible points. Nearly all essential adjusting arrangements can be manually operated. Its easy operation makes it simple to use by a single unskilled person. The machine is equipped with vertical wire straightening bearing rollers designed for straight wire feeding.

Special Features:

1. The machine is heavily constructed for high stability

2. Its main crank shaft is driven on bushes made of bronze and all other shafts are driven on branded bearings to give maximum speed and accuracy.

3. All cames, rollers, roller pins and other parts are made H. C. H. C steel properly heat-treated and grounded for long lasting.

4. High speed machine provides great saving of labour and lubrication cost which upgrades productivity and gives a competitive edge.

5. Due to its robust design, the vibrations and noise of the operating machine is low.

Company Details

Business Type

Exporter, Manufacturer, Supplier

Employee Count

14

Establishment

1966

Working Days

Tuesday To Sunday

GST NO

03ASTPS0452K1ZE

Certification

ISO 9001 : 2015

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 03ASTPS0452K1ZE

Amritsar, Punjab

Proprietor

Mr Jatinder Pal Singh

Members since

14 Years

Address

512, East Mohan Nagar, Amritsar, Punjab, 143001, India

cold heading machine in Amritsar

Report incorrect details