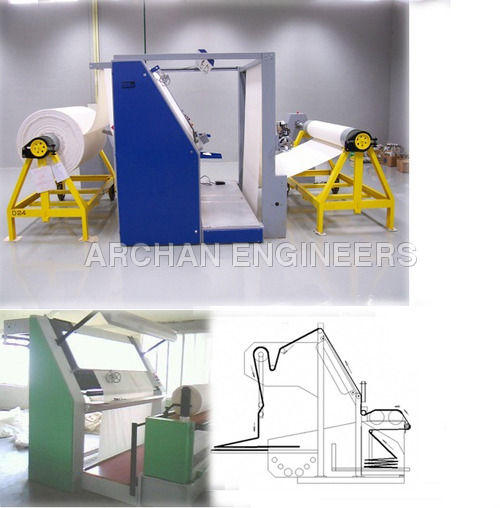

Bright Crome Plated Flocking Plant

Price:

Get Latest Price

In Stock

Product Specifications

| Roll Diameter | 900Mm |

| Coating Knife | Stainless Steel |

| Motor Power | 2Hp |

| Brushes | 6 Nos. |

| Heating Chamber | 32 Feet |

| Chamber Material | Steel |

| Max Temp | 70°C |

| Features | High Output, Durable Design, Easy Operation, Precise Flocking, Versatile Use, Automated System, Even Coating, Low Wastage |

Product Overview

Key Features

We are a remarkable entity in this industry, engaged in presenting fine quality Flocking Plant that is used in textile industry. The unique features of our machines include size from 12" to 72", heavy duty static device with gun attachment, auto cleaning attachment with vacuum system, suitable for cotton, garment, saree, dress material & paper and auto heating curing chamber with digital temperature controller. Our team of technical professionals precisely fabricate this plant by making use of excellent grade components in adherence with the defined international industry norms. To fulfill the diverse application requirements of clients, this Flocking Plant is offered in a range of technical specifications. Patrons can easily avail this plant from us at an affordable price range.

Features:

-

Ruggedness

-

Optimum performance

-

High operational fluency

-

Durability

(1) Un-winder (Cloth Feeding System) Non-vibrating

head structure for even results

(2) Coating Head

(I) Rolls dia =1 No.

(II) Roll Size =900mm (approxx.)

(III) S.S. Coating Knife =1 No.

(IV) Load =2hp (A.C. Driver)

(V) Up & Down Pneumatic System for Knife.

(VI) Pneumatically adjustment of coating roll for best coating and designing

(3) Rotary Head (Single Color Flock Print)

(I) Feeding pump with motor 2hp =1No.

(II) S.S. squeeze with stopper =1Set

(III) A.C. Drive (2hp) with gear box & motor =1Set

(4) Flocking Zone

(I) Hoppers (Dozzler & Feeder) + complete set with transparent window

(II) Brushes =6 Nos.

(III) Bitter Adjustable =4 Nos.

(IV) Charging & Earthing Plates =1 Nos.

(V) Electrostatic Generator =1 Sets

(VI) Heating Chamber OR Open Stenter (32feet) =1 Set

(5) Air Embossing Machine

(I) Air Blower with 20hp motor =1 No.

(II) Squeeze, slid system etc. =1 No.

(III) Rotary Head with A.C. Drive =1 Set

(6) Curing Oven (40 to 70) chamber or Stenter with Chain Narrow Wide System

1) Fuel: Electric / Gas

2) Total Load: Hp varies accordingly

(7) Brushing machine (Double brushing System) - 1 Nos.

Total Load: 9hp

(8) Winder (Clutch System Automatic) with A.C. Drive

Total load: 2 hp

(9) Cloth Inspection Machine

-

Very flexible design

-

Trouble free mechanism and drives

-

Allows inspection as well as mending of fabrics

-

Tension free unwinding and winding

-

Low power consumption

-

Soft start and instant stoppage of cloth

-

Cloth can run in FORWARD as well as REVERSE instantaneously

-

Variable machine speed - 0 to 40 Mtrs. Per Min

(10) Electric Panel Board designed such to operate all functions from

one end = 1 Nos.

MACHINE'S EXCLUSIVE FEATURES

-

Fully automated

-

P.T.F.E. coated conveyor

-

Heating Sensors with digital controller for even heating

-

Least wastage of powder

-

Reduce power consumption

-

Reduce heat loss

-

Even coating on fabric / plastic , etc.

It also includes the following Attachments :-

-

Heavy duty thirty feets long chamber with Rockwool sheets and heavy steel material

-

Pneumatically adjustment of coating rolls for best coating and designing

-

Non-vibrating head structure for perfect results

-

Electric/Gas fired chamber including necessary devices

-

Dynamic balance suction blowers with M.S. pipe for recollecting flock powder

-

Heavy duty static flock device for best flocking

-

Digital type temperature controller for best performance of coating and printing

-

Heavy duty electric motor with gearbox complete with all chains and chain wheels

-

Electric panel board with branded components

-

Standard make fully automated electric fired heaters

-

P.T.F.E. coated conveyor suitable for any size of fabric width 60

-

All rolls of machine from standard M.S. material

-

Rubber roll made from best quality rubber material

-

S.S. pipe for chemical applying with S.S. blade and rubber squeeze also

-

Heavy duty delivery end with cotton coated roll for quality coating

Company Details

Focusing on a customer-centric approach, ARCHAN ENGINEERS has a pan-India presence and caters to a huge consumer base throughout the country. Get Special Purpose Machines from ARCHAN ENGINEERS at Trade India quality-assured services.

Business Type

Exporter, Manufacturer, Service Provider, Supplier

Employee Count

20

Establishment

1988

GST NO

24ABYPR3738B1ZD

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 24ABYPR3738B1ZD

Surat, Gujarat

Managing Director

Mr. Sashank Raval

Address

Gate no -1, Office no. 16, 2nd Floor, Dhamanwala Service Complex, GIDC, Pandesara, Surat, Gujarat, 394221, India

flocking machines in Surat

Report incorrect details