Flexo Press Machine Vehicle Type: 4 Wheeler

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Steel |

| Dimensions | NA |

| Max. paper width | 470 mm |

| Max. printing width | 460 mm |

| Max. unwind roll diameter | 1270 mm |

| Max. rewind roll diameter | 800 mm |

| Paper thickness range | 35-160 g/m2 |

| Cross Perf. Cylinder | 10"-18" |

| Zigzag folding range | 6-18" |

| Features | High speed, Servo drive, Print quality, Stable design, Precision bearings, User friendly, Imported motors, Skew rectifying, Registration system, Module change-over, Web flipping |

Product Overview

Key Features

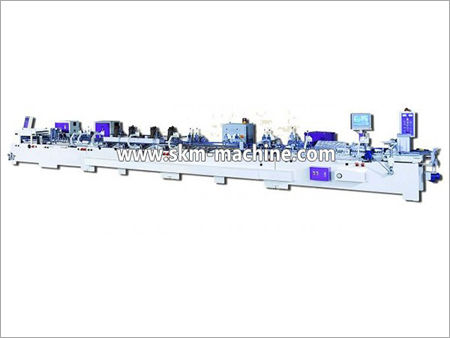

- Model: SMARTWORKER 105P

You can simply lessen and further reduce YOUR COST BY HIGHER PRODUCTION SPEEDby IN - LINE MEANS QUALITY the BYM SERIES which is WEB - FEDIN LINE / OFF - LINEHIGH SPEED ROTARY DIE CUTTING MACHINE IN - LINE WITH GRAVURE PRINTING PRESS MAKES THE WHOLE SHAFFLESSSERVO DRIVECOME TRUE

Key Features:

It comes with an automatic skew rectifying, tension control, registration, direct pressure, slitting, which further includes 2 to 3 modules (creasing / embossing / die cutting / sheeting), pile delivery flow splitting, timed flow, auto counting and stacking. The Web width : ranges from 820 mm

Paper Spec : 90 to 320 g per m2

Maximum line speed : 240 m per min (depending on the printing press)

Deviation between printing and die cutting : will be ranging from 0.20mm

Creasing and die cutting tolerance : ranges from 0.16mm

Shaft less (Servo - Driven) control makes the whole process shaft less when in combination with shaft less printing press

The Siemens PLC control and interface with touch screen display : it is user friendly and dependable

It has an Imported servo motors and efficient tension control systems

It also comes with Imported two - pole high accuracy skew rectifying

It also has an Imported registration system

Further it comes with a 4 patent awarded air - hose rail designs for simple and trouble free module change - over

It is basically Discretionary for web flipping over and cutting soft pack materials

Specifications:

- The machine has automatic skew rectifying feature, which makes it an efficient product. Further, it has 2 modules for processes of sheeting, die cutting, embossing, and creasing. Its other features are effective tension control, slitting, direct pressure, and registration; to name a few.

- For web flow, over and overhead bridge can be provided as optional

- Four-patent awarded for the machine's air-bag rail designs which allows simple module change-over

- Shaftless (Servo-Driven) control helps in making 100% process shaftless when used along side shaftless printing press

- The interface has a touch screen display, which is reliable and user friendly

- The machine has imported registration system and imported 2-pole skew rectifying mechanism which has high precision.

- The machine has integrated Siemens PLC control

Technical Details:

| I. Main Specification: | |

| Max. paper width | 470 mm |

| Max. printing width | 460 mm |

| Max. unwind roll diameter | 1270 mm |

| Max. rewind roll diameter | 800 mm |

| Paper thickness range | 35-160 g/m2 |

| Cross Perf. Cylinder | 10"-18" |

| Zigzag folding range | 6-18" |

| Max. printing speed | 180 m/min |

| Automatic lubrication system | 1 Set |

| Compressed air system | 1 Set |

| UV dryer | can been added |

| (operation speed will be changed by paper quality, kind of jobs and folding size, etc.) | |

| II. Detail Function : | |

| 1.Unwind Station | |

| Paper width | 470 mm |

| Roll Dia. | 1270 mm |

| Core I.D. | 3" |

| Side adjustment(left and right) | +15 mm |

| Brake | Air-cooled powder brake |

| Web end detector | 1 Set |

| Infeed roller(18" circumference) | 2 pcs |

| Web guide device (BST) | 1 Set |

| Punch hole pitch control system | 1 Set |

| Web break detector | 1 Set |

| 2.Off Set Station | |

| Max. printing width | 460 mm |

| Dampening system | dampening system |

| PS Plate thickness | 0.15 mm |

| Blanket thickness | 0.95 mm |

| Exchange cassette | 10"-18" |

| Register control |

|

| Lateral registration(handle rotation) | +5 mm |

| Lineal registration(reversible motor) | 3600 |

| Plate bender | 1 Set |

| Cassette trolley | 1 Set |

| Cassette stock table | 3 Set |

| 3.letterpress station | |

| Exchange plate cylinder | 8"-18" |

| Numbering device | 10"-24" |

| Plate thickness | 0.95 mm |

| Adhesive tape thickness | 0.05 mm |

| Impression cylinder(steel) | 17" |

| Register control |

|

| Lateral registration(handle rotation) | +5 mm |

| Lineal registration(reversible motor) | 3600 |

| 4.process station | |

| Punching device 22"circumference | S-W-S |

| Slitter( shear cut type) | 2 Set |

| Blower for trim removal | 1 Set |

| Drag roller 12" circumference | 1 Set |

| Length perf. device | 5 Set |

| Cross perf. device(cassette exchange type) | 2 Set |

| Sheet cut device | 1 Set |

| 5.fold station |

|

| Folding range(by gear change) | 6"-18" |

| Drag roller 12" circumference | 1 Set |

| Check marking device | 1 Set |

| Static electricity eliminator | 1 Set |

| Web break detector | 1 Set |

Company Details

Focusing on a customer-centric approach, SKM MACHINE CO., LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Printing Machinery in bulk from SKM MACHINE CO., LTD. at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

50

Establishment

2009

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Shanghai, Shanghai

Ms. Lisa Liu

Address

No. 226, Taopu Road, Shanghai, Shanghai, 200333, China

hot press machine in Shanghai

Report incorrect details