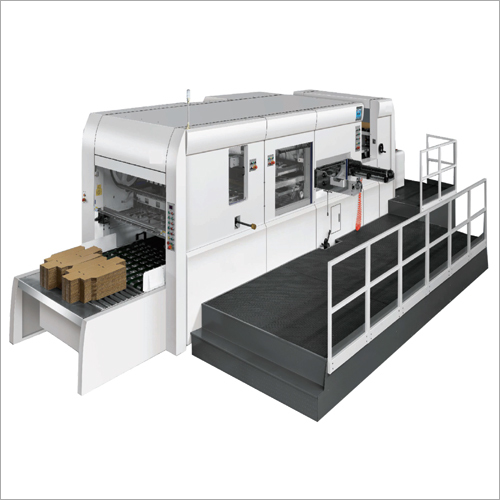

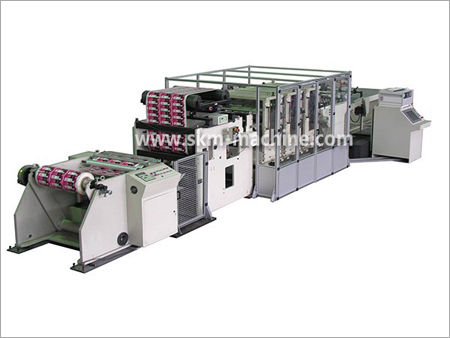

Automatic Die Cutting & Creasing Machine - Web Width 1300 Mm, Paper Specs 200-320 G/m2 | Servo-driven, High Precision, Auto Counting, Compact Design, Stable Operation

Price:

Get Latest Price

In Stock

Product Specifications

| Web Width | 1300 Mm |

| Paper Specs | 200-320 G/M2 |

| Max Speed | 350 M/Min |

| Deviation | 0.20 Mm |

| Tolerance | 0.16 Mm |

| Control | Servo-Driven |

| Plc | Siemens |

| Features | High Precision, Simple Operation, Auto Counting, Compact Design, Efficient Tension, Quick Operation, High Accuracy, Stable Operation, Skew Rectifying, Pile Delivery |

Product Overview

Key Features

Features:

- It comes with an involuntary skew rectifying, efficient tension control, registration, direct pressure, slitting, which includes 2 modules (creasing / embossing / die cutting / sheeting), pile delivery, flow splitting, timed flow, and auto counting and stacking

- Web width : 1300 mm

- Paper Spec : 200 g - 320 g per m2

- Maximum spec : 350 m per min (depending on the printing press)

- Deviancy between printing and die cutting : 0.20 mm

- Creasing and die cutting tolerance : 0.16 mm

- Shaft less (Servo - Driven) control makes the entire process shaft - less when in combination with shaft - less printing press.

- The Siemens PLC control and interface with touch screen display : it is quite user friendly and dependable

- The Imported 2 - pole high accuracy skew rectifying

- The Imported record keeping system

- Four - patent awarded air - bag rail designs for simple and trouble free module change -over

- It has Non - compulsory for web flipping over and overhead bridge for the web flow

Specifications:

The machine has automatic skew rectifying feature, which makes it an efficient product. Further, it has 2 modules for processes of sheeting, die cutting, embossing, and creasing. Its other features are effective tension control, slitting, direct pressure, and registration; to name a few.

| Web Width | 1300 mm |

| Paper Specs | 200-320 g/m2 |

| Maximum Specs | 350 m/min (Depending on Printing Press) |

| Deviation Between Printing and Die Cutting | 0.20 mm |

| Creasing and Die Cutting Tolerance | 0.16 mm |

- For web flow, over and overhead bridge can be provided as optional

- Four-patent awarded for the machine's air-bag rail designs which allows simple module change-over

- Shaftless (Servo-Driven) control helps in making 100% process shaftless when used

Company Details

Focusing on a customer-centric approach, SKM MACHINE CO., LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Cutting Machine in bulk from SKM MACHINE CO., LTD. at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

50

Establishment

2009

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Shanghai, Shanghai

Ms. Lisa Liu

Address

No. 226, Taopu Road, Shanghai, Shanghai, 200333, China

Report incorrect details