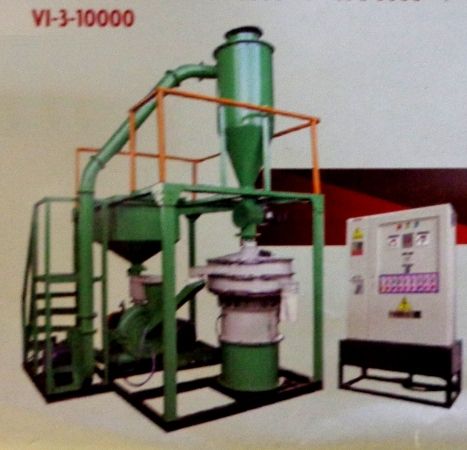

Extruxion Lines For Colouring Reprocessing Granules

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Steel, Plastic |

| Dimensions | Variable |

| Power | Variable |

| Weight | Variable |

| Capacity | Variable |

| Speed | Variable |

| Voltage | Variable |

| Features | Easy Installation, Long Life, Low Consumption, Efficient Polishing, Durable Design, Precise Finishing, Versatile Use |

Product Overview

Key Features

With

rich knowledge and industry experience, we manufacture, export and

supply a vast array of Extrusion

Lines For Coloring Reprocessing Granules.

This

machine is manufactured under the guidance of our skilled

professionals with the use of optimum quality components and advanced

technique as per the set industry norms. Offered machine is mainly

used in industries like ceramic, cement, plastic etc. for granule processing.

We provide this Extrusion

Lines For Coloring Reprocessing Granules

in varied technical specifications at reasonable prices.

Features:

Smooth

functioning

Easy

maintenance

Energy

efficient

Excellent performance

The LLDPE raw material with suitable masterbatch is being fed in to the barrel cylinder through storage hopper. The barrel is preheated by heating zones and suitable temperature control system to process the input material. The rotating screw pushes the material towards die end with uniform and homogenized plastics melt. The screw is rotated by suitable AC motor coupled with heavy duty gearbox.The plastics strands extruded from die are fed in to high speed Pelletiser unit after they get cooled and traveled through SS water cooling tank. Pelletiser cuts the strands in to desired size of pellets which can be collected in to storage silo.Specifications:Screw & barrel are made of nitro alloy steel, nitrided, finished polished and duly hardened for longer life.All Electrical switch gears are of reputed & reliable make.Digital temperature controllers for faster heating & energy saving.AC variable drive as standard feature for Pelletiser unit.Designed for reprocessing & coloring application of LLD, LDPE, HDPE, etc. Technical Specifications: Particular Unit Models AEX-75 AEX-90 AEX-100 AEX-110 Main Motor kw 18.25 22.25 37.25 45 Output in LLDPE Kgs/hr 120 150 200 250 Floor space Required Mtr 7.5x2.0x2.0 9.0x3x2.2 9.5x3x2.2x 9.5x3x2.2

Company Details

Focusing on a customer-centric approach, ASHWIN ENGINEERS has a pan-India presence and caters to a huge consumer base throughout the country. Buy Rotomoulding Machines in bulk from ASHWIN ENGINEERS at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

20

Establishment

1992

Working Days

Monday To Sunday

GST NO

24AHWPP8816A1Z2

Related Products

Explore Related Categories

Seller Details

GST - 24AHWPP8816A1Z2

Ahmedabad, Gujarat

Proprietor

Mr Ashwin Panchal

Address

Plot No. 1216/29, Phase-IV, GIDC, Near Dishman Pharmaceuticals, Naroda, Ahmedabad, Gujarat, 382330, India

reprocess granules in Ahmedabad

Report incorrect details