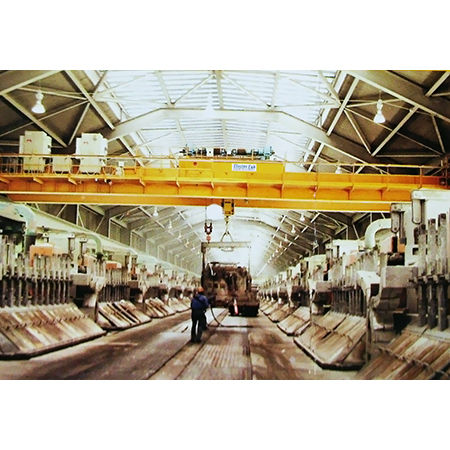

Electric Overhead Traveling Crane - Rolled Steel I Section, 15 Ton Capacity, 25 M Span, Yellow | Emergency Stop, 220 To 415 Volt, User-friendly Control Systems

Price:

Get Latest Price

In Stock

Product Specifications

| Application | Industrial |

| Color | Yellow |

| Emergency Stop | Yes |

| Condition | New |

| Voltage | 220 to 415 Volt (v) |

| Main Domestic Market | All India |

Product Overview

Key Features

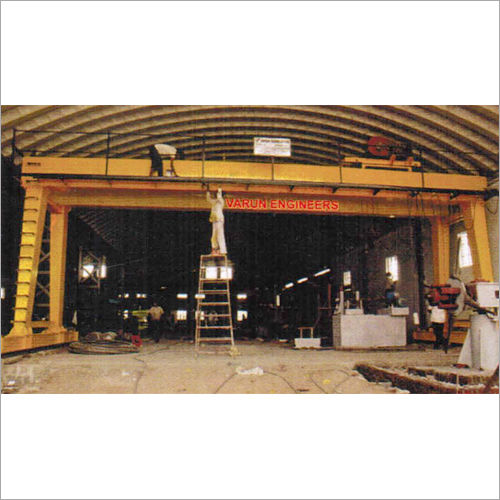

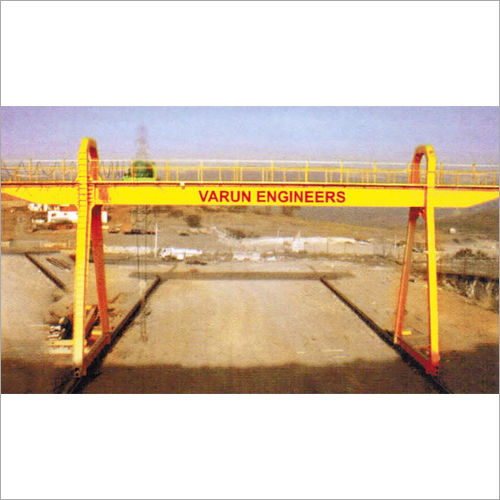

Electric Overhead Traveling Crane

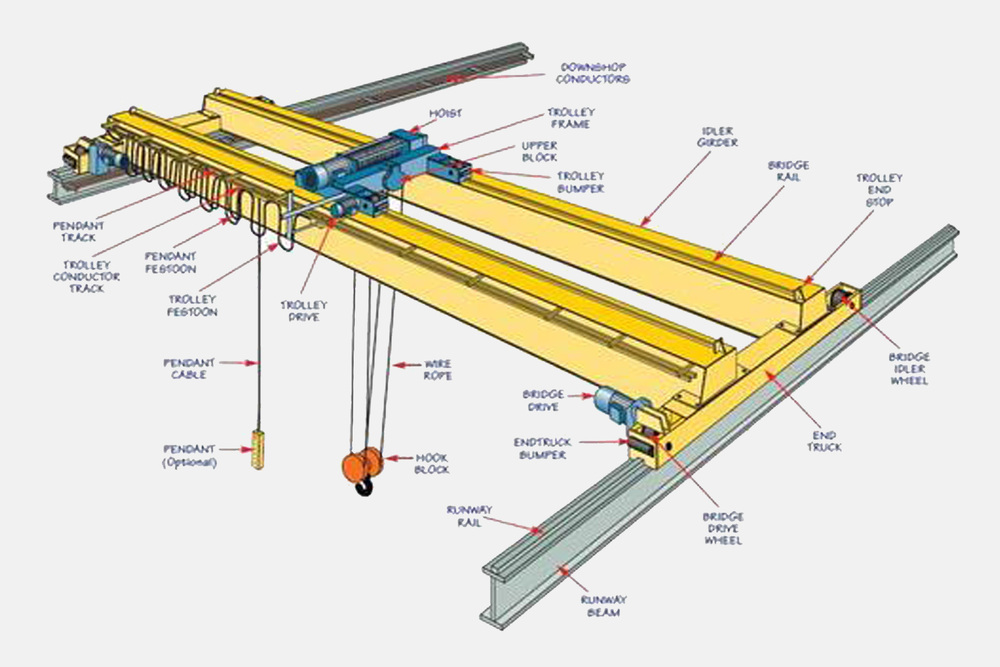

The Electric Overhead Traveling Crane are designed in accordance with IS: 807, IS: 3177. Suitable factor of safety are considered as per duty class I, II, III & IV the crane bridge is designed either from Rolled Steel I Section or fabricated with Plates. End carriage are fabricated from Rolled steel I - section or with plates & provided with L- type(Housing) double flanged or Pad plate type wheels of suitable diameter of wheels with spherical roller bearings.

Capacity : Up to 15 Tons

Span : Up to 25 Mtr.

Lift of height : 6 Mtrs & Above

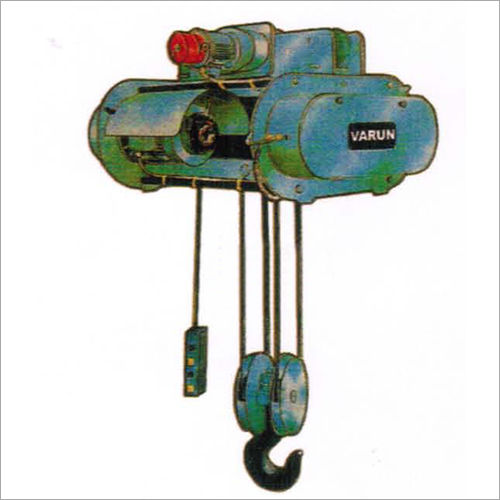

Hoist Unit:-

Varun Hoist unit are designed in accordance with is 3938 having modular construction suitable to run on I section or Box girder. Hoist & cross travel motor, gear box, and Brake are easily accessible for maintenance.

Long Travel Drive:-

Either twin or centrally driven provided depending on span length and capacity of the crane .

Control Equipment:-

Operated through push button station or Cabin operated with master control or remote control.

Control Panel:-

Each motor is operated by push button through contactors having Control voltage of 24V/110V for safety of operator. Protective panel consisting of overload relay, MCB / Fuses housed in control panel box. Electrical supply shall be AC 3ph, 400/440V, 50HZ

Test Load:-

The crane shall be tested at 25% overload of safe working load, Test load are to be arranged by purchaser at site.

Special Features:-

Designs conform to IS-807, IS-3177.Optimum Design ensuring minimum Dead Weight, Wheel Loads, Head Rooms and Clearances.Forged Runner Wheels on Spherical Roller Bearings, resulting in long trouble free service.Hobbed and Run-In Heat Treated Gears form High Carbon & Alloy Steels for long trouble free service.Standardized Unit Sub-Assemblies used for complete range, ensuring possibility of spares supply form stocks.Quick Deliveries and Prompt after Sales Service

Designed:-

Amply Proportioned Main Girder and End Carriages form Rolled Sections, with cover Plates or Fabricated Girder. Main Girder further stiffened with Auxiliary Girder and End-Tied to End Carriages, restricting the Equivalent Length & Compressive Stresses.Well Proportioned Rotating Axle type Runner Wheels on US-SGEOT Cranes. Rope Drum fabricated form IS-226, stress relived & long seams 100% Radio graphed.

Bridge Drive:-

Single/Twin Drive with Squirrel Cage/Slip Ring Induction Motors through Totally Enclosed, oil Immersed, Helical Gearboxes in case of SGEOT Cranes.Twin Drive through Unique Conical Rotor type Squirrel Cage Induction Geared Motors with built-in fail safe brakes in case of US-SGEOT Cranes.

Motors:-

Unique Conical Rotor Type Squirrel Cage Induction Hosting Motors with built-in Brakes for Hosting and Cross Travel, Foot Mounted, IEC Frame Size, Crane Duty Motors for Long Travel. Insulation class for all motors B/F.

Brakes:-

Built-in Electro Mechanical Brakes for Hosting and Cross Travel Motions.Electro Hydraulic Thrusters for Long Travel in case of SGEOT Cranes and Built ?in Electro Mechanical Brakes in case of US-SGEOT Cranes.

Crane Control:-

From Floor through Pendant Push Buttons, operating at 100/24V.Electrical Switch Gears mounted inside a dust proof Control Panel, with suitable access for maintenance.

Power Supply System:-

To Hoist & Cross Travel through Trailing Cables. To crane through Trailing Cable / M. S. Angle iron Conductors / bare Copper Conductors to customer choice.

Company Details

Business Type

Manufacturer, Service Provider, Supplier

Employee Count

55

Establishment

2008

Working Days

Monday To Sunday

GST NO

36AAGFV8606D1Z4

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 36AAGFV8606D1Z4

Hyderabad, Telangana

Accepts only Domestic inquiries

Managing Partner

Mr A. Nageswar Rao

Address

Sy. No. 15/VU, Suraram-Village, Quthbullapur Mdl., Ranga Reddy, Hyderabad, Telangana, 500055, India

overhead traveling cranes in Hyderabad

Report incorrect details