Copper Rod Continuous Casting And Rolling Line - 8mm Low Oxygen Bright Copper Rod Production | High Production Efficiency, Low Energy Consumption, Continuous Casting And Rolling Process

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Steel |

| Dimensions | Variable |

| Power | High |

| Capacity | 8Mm Rod |

| Process | Continuous |

| Sections | 6-Wheel |

| System | Electric Control |

| Features | High Efficiency, Low Energy, Simple Structure, High Quality, Continuous Casting, Continuous Rolling |

Product Overview

Key Features

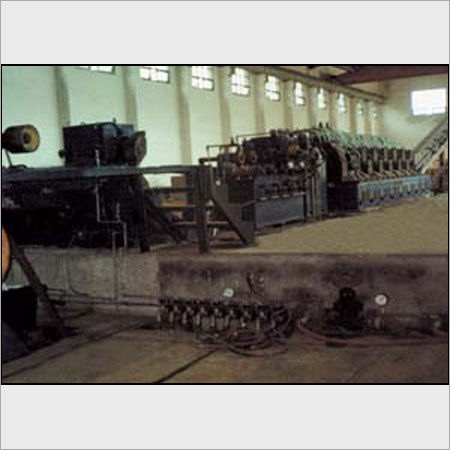

It is composed of melting copper refining furnace, six-wheel continuous casting machine, auxiliary machine, rolling mill, copper rod cooling, reverting and take-up unit, emulsion cooling system, lubrication system and electric control system etc.

Using red copper scraps, reflection refining furnace should be employed. If raw material is electrolytic copper, 8 tons shaft furnace (continuously producing).

2. Process Flow

Feeding, melting and refining -holding furnace -flume-continuous casting (casting ingots) -forward hauling -casting ingot treatment unit (shearer, conveyor, alignment, edge shaving, straightening, brushing machine) -rolling machine (automatic feeding)-continuous rolling-copper rod cooling and surface recovery treatment unit -continuous rod coiler -take-up (hydraulic take up) -roller bed conveyors -compressor-rod coiler

Company Details

Focusing on a customer-centric approach, Chengdu Shuhong Machinery Co., Ltd. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Machineries in bulk from Chengdu Shuhong Machinery Co., Ltd. at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Establishment

1996

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Chengdu, Sichuan

Mr. Peter Liu

Address

3-1203 Zhengcheng Wealth Territory, No.19 Beidajie, Chengdu, Sichuan, 610017, China

roll linings in Chengdu

Report incorrect details