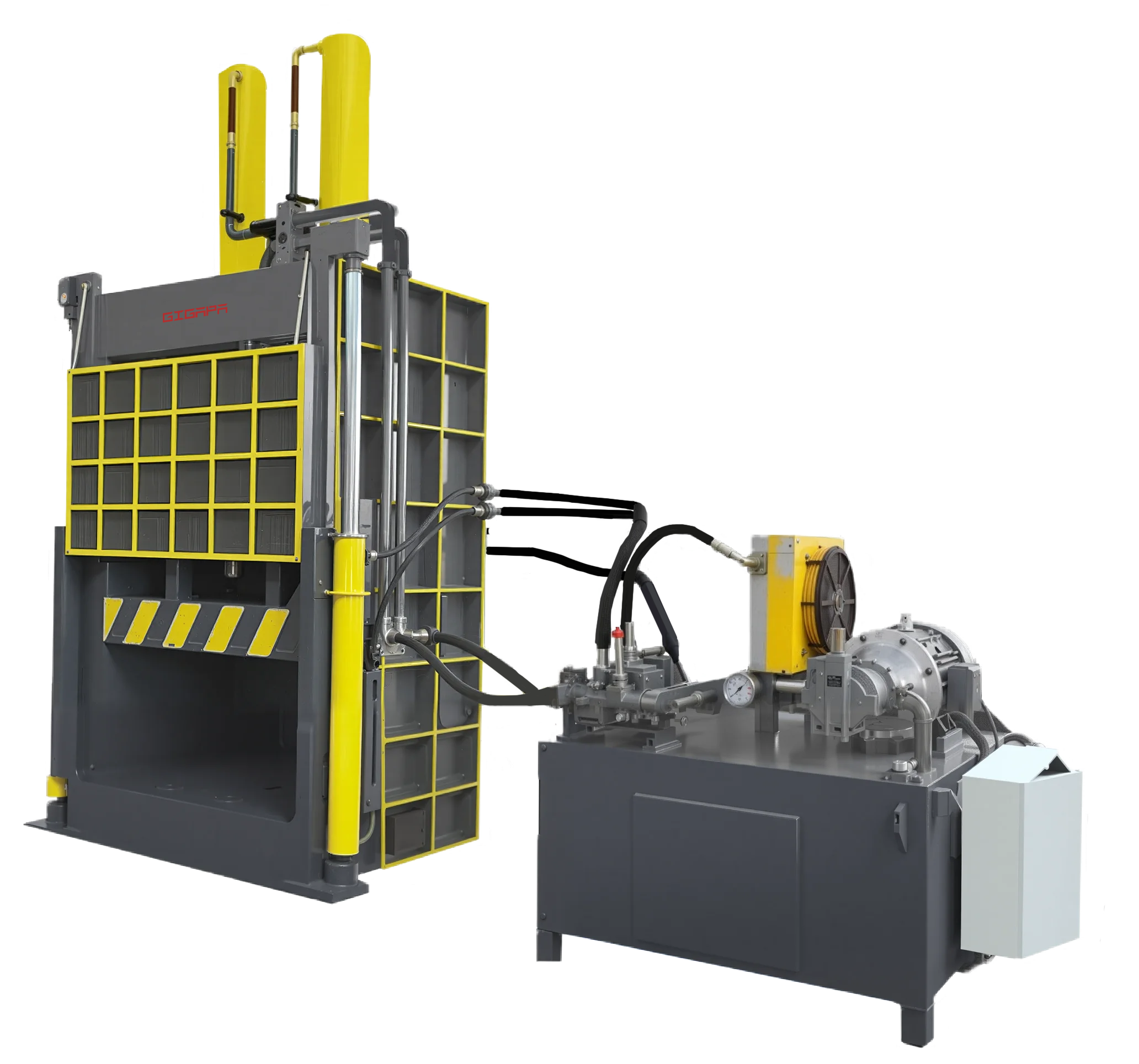

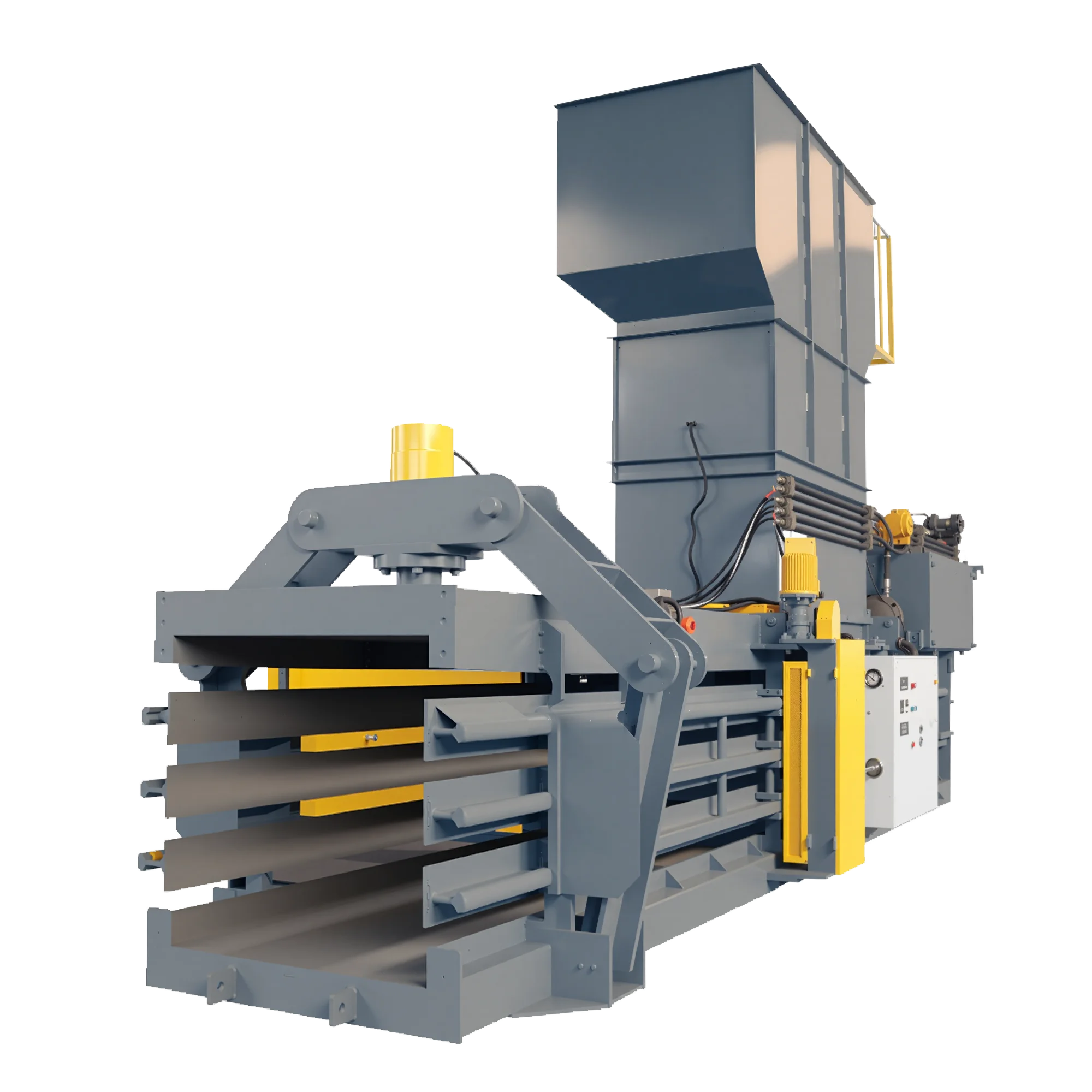

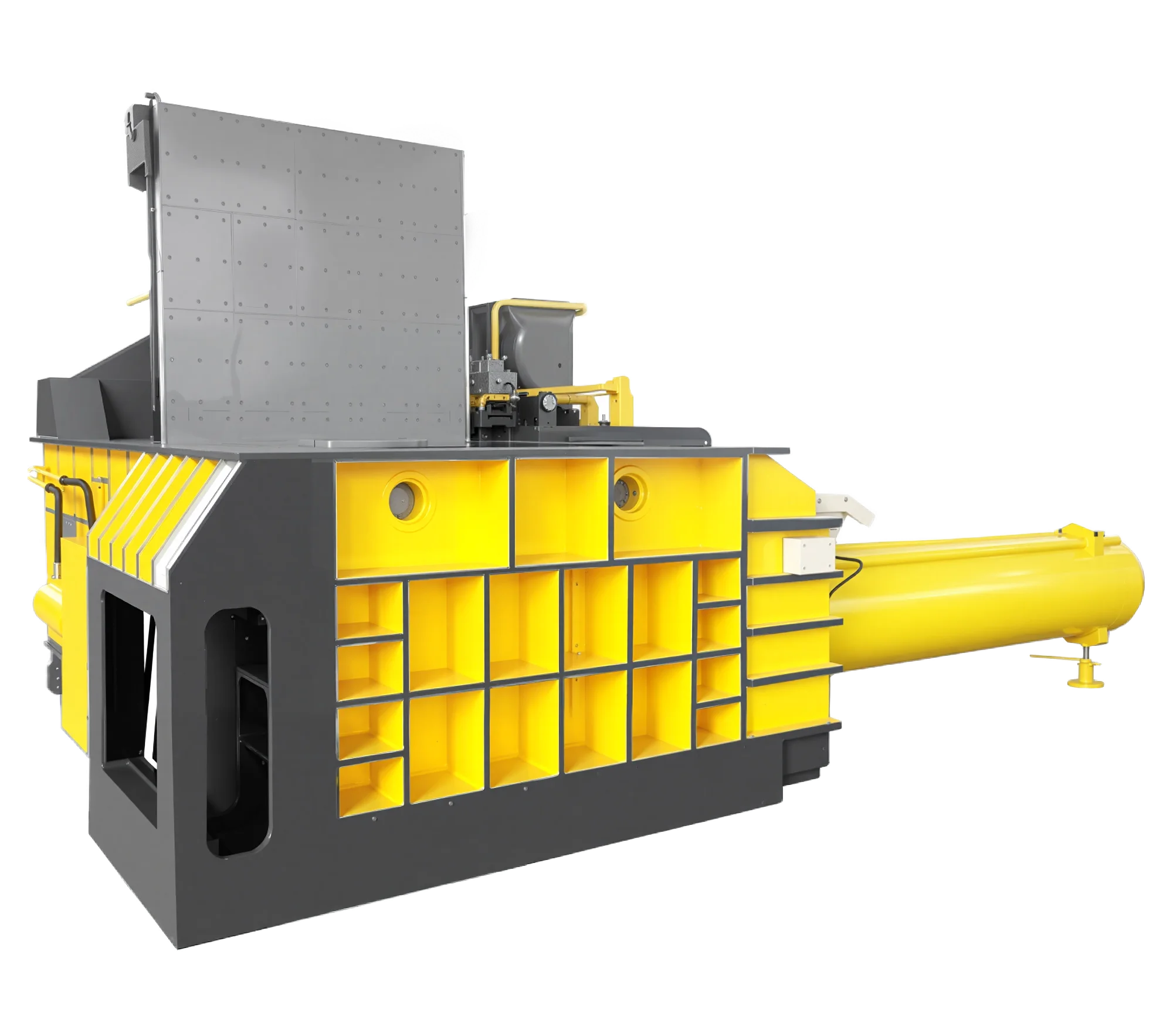

Continuous Metal Baling Machines

Price:

Get Latest Price

In Stock

Product Specifications

| Application | Industrial Use |

| Product Type | Continuous Metal Baling Machines |

| Usage | Industrial Use |

| Mounting Type | Foot-Mounted |

| Power Source | Electric |

| Color | Grey |

| Features | Low Maintenance |

| Body Material | Steel |

| Payment Terms | Letter of Credit at Sight (Sight L/C), Others, Telegraphic Transfer (T/T) |

| Supply Ability | 10 Per Month |

| Delivery Time | 1 Week |

| Sample Policy | Contact us for information regarding our sample policy |

| Packaging Details | Standard Packaging |

| Main Export Market(s) | Asia |

| Main Domestic Market | All India |

Product Overview

Key Features

Company Details

Nantong GIGAPA Technology Co., Ltd. focuses on the field of machinery, mainly engaged in the research and development, production, and sales of hydraulic cylinders, hydraulic stations, hydraulic equipment, environmental protection equipment, renewable resource processing equipment, solid waste resource equipment, and other products. The main products we produce include single-shaft crushers, double-shaft shredders, wood shavings machine, fully automatic baling machines, bagging baling machines, etc. The company’s team has more than ten years of research and development and manufacturing experience in related fields. The company is located in Rugao City, Jiangsu Province, the hometown of longevity in the world. The R&D and sales offices are located in Rugao Smart Valley Science and Technology Park, and the production plant is located in Baipu Town, a strong industrial manufacturing town.

Business Type

Manufacturer, Supplier

Employee Count

15

Establishment

2024

Working Days

Monday To Friday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Nantong, Jiangsu

Sales Manager

Mr Wu Jing Jing

Address

Zhihui Valley, Rugao, Nantong, Nantong, Jiangsu, 226500, China

baling machine in Nantong

Report incorrect details