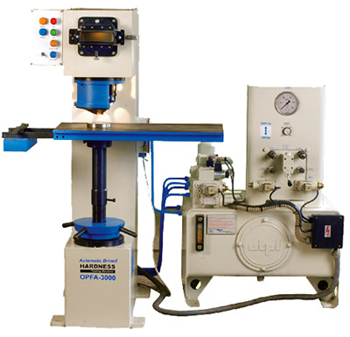

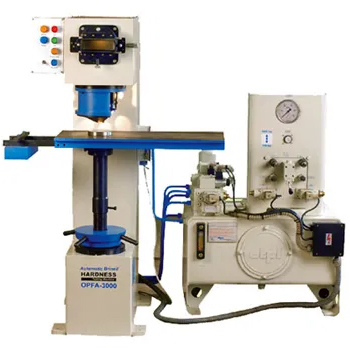

Computerised Optical Brinell Hardness Tester

Price:

Get Latest Price

In Stock

Product Specifications

| Load type | Hydraulic |

| Load steps | Four |

| Measurement modes | Auto/Manual |

| Optics | Matched |

| Camera | CCD |

| Software | Windows-based |

| Usage | Brinell hardness measurement of cast or forged components. |

| Accuracy | High |

| Standards | Relevant ISO |

| Dimensions | Check manual |

| Weight | Check manual |

| Features | Hardness testing, Optical measurement, Computerized system, High accuracy, Batch testing, Wide range, Easy operation, Data analysis |

Product Overview

Key Features

FEATURES :

1. The machine has a C-Type load frame.

2. This machine has been designed for production testing & for continuous operation.

3. This machine is used to measure Brinell Hardness Value of cast or forged components.

4. Wide range of testing with 4 load steps.

5. Hydraulically loading / unloading system is provided with load / unload knob for operation.

6. Full computerised system for indentation measurement and display.

7. Window based software system.

8. Accurate measurement of Brinell hardness through matched optics, CCD Camera, Hardware & software using advanced image processing technology.

9. On removal of load the optics will transfer the image of indentation to CCD. The image is further digitalized and processed by PC for measurement. The diameter of the image can be measured automatically / manually to give Brinell hardness value.

10. Two modes of measurement a Manual & Auto.

11. In Auto mode the image is scanned for measurement & hardness is displayed automatically.

12. Verification facility is provided for clear indication of measured impression by encircling the same.

13. Windowing facility is provided which encircles the blurt images for better accuracies.

14. Macro & Micro adjustment facilities are provided in manual mode for fast & accurate encircling of the image to be measured.

15. Batch testing facility is provided.

16. Statistical Analysis repo

Company Details

TRUEMET by Om Engineering Instruments: Your Trusted Partner in Material Testing and Metallurgical Solutions

OEI is the leading Manufacturer, Supplier, and Exporter of various ranges of Material Testing Machines and Metallurgical Equipment under the brand TRUEMET. With a commitment to excellence and a relentless pursuit of quality, we have established ourselves as a trusted partner for industries seeking reliable and accurate solutions for their testing and analysis needs.

Our material testing machines, including Hardness Testing Machines and Universal Testing Machines, are designed to meet the highest standards of precision and performance. Each machine is meticulously engineered and can be computer-controlled, ensuring precise and repeatable results. Whether it’s evaluating the hardness of a material or conducting a comprehensive mechanical analysis, our TRUEMET machines provide the reliability and accuracy that businesses can trust.

In addition to our exceptional material testing machines, TRUEMET also offers a range of advanced metallurgical equipment. Our Metallurgical Microscopes, equipped with Truemet metallographic image analysis software, empower researchers and engineers to explore the intricate details of material structures with unmatched clarity and precision. Furthermore, our Weld penetration inspection software, TrueWeld, ensures the integrity and quality of welded joints. Additionally, our Sample Preparation Equipment streamlines the process of specimen preparation, enabling efficient and accurate analysis.

At TRUEMET, we are committed to delivering solutions that empower businesses to make informed decisions based on reliable data. With our state-of-the-art equipment, advanced software, and a team of dedicated professionals, we strive to provide unmatched customer satisfaction and technical support.

We are constantly expanding our after-sales activities including Installation, Calibration, and Repair Services. For both our repair and calibration services we aim for the shortest possible turnaround times.

Experience the precision, reliability, and innovation that TRUEMET brings to the world of material testing and metallurgical solutions. Partner with us and unlock a new level of confidence in your testing processes.

Business Type

Exporter, Manufacturer, Supplier, Wholesaler, Retailer, Dealer

Employee Count

30

Establishment

1999

Working Days

Monday To Saturday

GST NO

07AHQPK4683C1Z4

Payment Mode

Cheque

Certification

ISO/IEC 17025:2005

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 07AHQPK4683C1Z4

Delhi, Delhi

Quality Cum Technical Manager

Mr Rajeev Kumar Sharma

Members since

21 Years

Address

H.No.6, Street No. 1, RST Enclave, Johripur Extension, Delhi, Delhi, 110094, India

Report incorrect details