Cold Forming Elbow Making Machine Capacity: 10 Pcs/min

Price Trend: 65000-75000 USD / Set

Get Latest Price

Minimum Order Quantity :

1 Set

In Stock

Product Specifications

| Product Type | Cold Forming Elbow Machine |

| General Use | Forming Elbow |

| Type | Other |

| Capacity | 10 Pcs/min |

| Weight (kg) | 5000 Kilograms (kg) |

| Computerized | No |

| Automatic | Yes |

| Touch Screen | Yes |

| Control System | PLC Control |

| Surface Treatment | Other |

| Drawing | 2D |

| Voltage | 220/360v Volt (v) |

| Dimension (L*W*H) | 3*1.3*2.5 Meter (m) |

| Color | Blue /green |

| Warranty | 1 year |

| FOB Port | Tianjin Port |

| Payment Terms | Letter of Credit (L/C), Telegraphic Transfer (T/T), Western Union |

| Supply Ability | 30 Per Year |

| Delivery Time | 25-30 Days |

| Sample Policy | Contact us for information regarding our sample policy |

| Packaging Details | wooden box /wooden pallet |

| Main Export Market(s) | South America, Eastern Europe, Middle East, Africa, Asia |

| Main Domestic Market | All India |

Product Overview

Key Features

1. Design and manufacturing.

2. Installation.

3, debugging.

Second, the performance

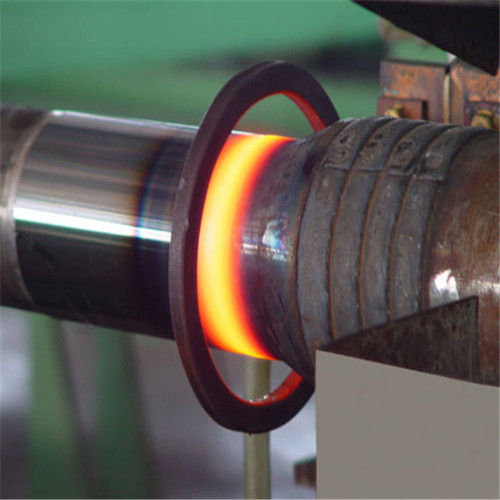

1. Used for cold push molding of stainless steel elbow.

2. Rated working pressure of oil is 25Mpa.The experimental pressure of the oil cylinder is 31.5MPa

3, master cylinder pressure 300T two, (cylinder inner diameter 280mm) effective stroke 700mm.

4. Side cylinder pressure is 180T, (cylinder inner diameter is 300mm) effective stroke is 700mm.

5. Elbow forming range diameter 114-168mm.

6. Motor power 18.5KW.

7, 90A A A A reversal mandrel demoulding

8, the environmental conditions of cold push machine: ambient temperature 5-38 degrees, relative humidity A AcA A A A 82%, input voltage of three-phase four-wire 380V (-12%-- +15%), frequency of 50HzA A A A 2%.The working time can be 24 hours a day continuous work, the air is free from corrosive media, the equipment must be operated in the workshop, there is enough space.

9, using YB-N46 anti-wear hydraulic oil.

Three, cylinder standard

1. The manufacture of oil cylinder conforms to JB/T10205-2000 and JB/T15622-2005 standards.

2. The cylinder is 45# steel, the inner surface finish is Ra0.3, the piston rod is 45# seamless tube, the surface is chrome plated, polished after plating, no straight lines, spiral lines, finish is Ra0.4.

3. The other parts of the cylinder are made of 45# forgings to ensure mechanical properties.

4. The piston guide sleeve of the main cylinder adopts copper sleeve, all seals adopt standard priority series, and the main oil seal is imported from Austria ACO.

5. Before the assembly of the cylinder, the smoothness, hardness, matching size and other items of the cylinder and piston rod shall be inspected, and the quality of the forgings and seals shall be inspected. The parts used in the assembly of the cylinder shall meet the standards, and the pressure test shall be carried out after the assembly of the cylinder.

Four, host,

1. The main structure is three-beam and four-column structure. The equipment includes upper beam, lower beam, slider, link column, nut, cylinder and reverse material device, etc.The three beams are welded with Q235-A high quality steel plates.Use 16Mo high quality welding wire to ensure the strength.All structural parts are machined by numerical control machine to ensure accuracy.

2. Maximum opening height of the slider: 900mm.

3, the effective size of the working table: about 800mm- front and rear 950mm(excluding the side cylinder part)

4. There is a main oil cylinder installed on the horizontal center line of the upper beam. The piston rod of the oil cylinder is connected with the slider through the offsetting flange.The side cylinder piston drives the top bar to move along the slide.

5, equipment dimensions: 3300mm*1500mm*3100mm

6, equipment weight: 14T

Five, hydraulic pump station

1. The maximum working pressure of the hydraulic system is 25Mpa, and the experimental pressure is 31.5Mpa.

2, the inside and outside surface of the oil tank for anti-rust treatment, installed in the oil tank filter, set liquid level, oil temperature display.

3, the whole hydraulic system must be cleaned before oil injection test operation.

4. The pump station is designed as an integrated connection to reduce leakage points.The oil pump adopts manual variable axial piston pump with adjustable flow, maximum internal pressure of 31.5Mpa and service pressure of 25Mpa.The system has overload overflow, flow adjustment, time control, PLC self - diagnosis and other functions.

5. The pump station is installed on the top platform of the equipment, which can effectively reduce the length of the pipeline and reduce the oil leakage point and save space.

Six, PLC function

1, PLC control, one key molding.Put the pipe into the mold and press the start button to automatically push the system and take out the finished product.

2, PLC can display speed, distance, the number of each working hour and hydraulic oil self-diagnosis.

Company Details

Business Type

Exporter, Manufacturer, Distributor, Supplier, Trading Company

Employee Count

30

Establishment

2008

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Hebei, Hebei

Ceo

Ms. Darcy Dong

Members since

12 Years

Address

Dongguang County, Cangzhou City, Hebei, Hebei, 061600, China

elbow forming machine in Hebei

Report incorrect details