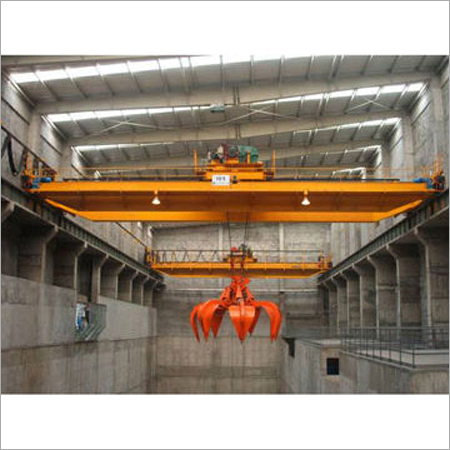

Coil Grab With Fixed Claws

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Welded Steel |

| Color | Yellow |

| Max Load | 20-35tn |

| Power | 400V;50Hz |

| Dimensions | Variable |

| Surface Treatment | EPPUR120/2-FeSa2,5 |

| Weight | 1.6-3.4tn |

| Features | Safe Lifting, Secure Grip, Durable Design, Corrosion Resistant, Efficient Handling, Easy Operation, Precise Control |

Product Overview

Key Features

With the rich industry experience in the respective domain, we are offering our clients an exclusive range of Coil Grab With Fixed Claws. These Coil Grab With Fixed Claws are in standard specification as well as corrosion resistant. We offer these at market leading rates.

ECG 20-35 Coil Grab's structure consists of welded steel composition. Used material is S355 SFS-EN. All telescoping shaft's guide tracks are machined. Lifting hook's hole and bolt are measured for each hoist concerned and for every hook individually. Lifting hook's safety bolt is a standard accessory. Telescoping shafts are made of welded steel composition, material is S355 SFS-EN. Manufacturing material of shaft's wear pads depends on the handled material. The material of telescoping shaft's claws can be changed according to the handled coil's dimensions and material.

Coil grab's functions

The grab's telescope usage in a standard motor/transmission use. Surfacing is driven steplessly by the motor to open and close directions. Motor is enabled with stopping automatics and breaks to prevent free movement. Stopping automatics recognizes forks extreme positions and the edge of the coil. Forks are equipped with an overload switch so telescoping shafts' inner faces don't damage roll's edges when fork is being closed. To prevent the forks from opening during the lifting process the motor for telescopes is sized so that while loaded (min. load 1000kg) the motor isn't able to open the telescopes.

Accessories

- Suspension with an adapter connection

- Profibus connection and other connections required by automatic lifter

- Radio control, mono directional

- Possibility to add inductive edge sensor ( no compression against roll's edge)

Connections

- Mechanical connection for most common standard hooks. Special hooks and connections are provided on request.

- Electrical connection 400 V / 50 Hz + 5 %. Controls 230 V / 50 Hz.

- Electrics to terminal block. Delivered without a plug or delivered with a customer relating plug on request as an accessory.

Surface treatment

EPPUR120/2-FeSa2,5 ( = 120 ). Shade of color RAL 1006 ( yellow ). Different surface treatment on request.

Documents

Maintenance and operation instructions, CE certification, conformity assurance, spare part catalogue and related drawings are enclosed in the delivery. Documents are also delivered in digital form.

Approvals

BOFO products are designed and manufactured by Rannikon Konetekniikka Oy from high-class materials and products are tested at our factory before delivering them to customers. Manufacturing process always follows necessary standards and regulations set by authorities.

| General technical information: | ||||||

| Propulsion rollers with ball bearings | 8 | 0 | ||||

| Max load | tn | 20 | 30 | 30 | 35 | |

| Unloaded weight | tn | 1,6 | 1,8 | 2,98 | 3,4 | |

| Power for connection purposes 400V;50Hz | kW | 1,2 | 1,2 | 1,6 | 1,6 | |

| Torque | Nm | 15 | 15 |

| ||

| Max width | A | mm | 2530 | 2530 | 2450 | 3050 |

| Min width | B | mm | 1400 | 1400 | 1800 | 2260 |

| Max opening | C | mm | 1800 | 1800 | 1850 | 2250 |

| Min opening | D | mm | 100 | 100 | 300 | 200 |

| Shaft + Claw | E | mm | 365 | 365 | 300 | 400 |

| Claw | F | mm | 200 | 200 | 150 | 250 |

| Max depth | G | mm | 840 | 840 | 900 | 840 |

| Max height | H | mm | 2245 | 2445 | 2800 | 2900 |

| Shaft height | I | mm | 700 | 900 | 1000 | 1200 |

| Claw height | J | mm | 225 | 225 | 180 | 200 |

| Suspension hook max. | K | mm | 220 | 220 | 220 | 220 |

| Secondary lifting hooks 4 pcs | tn | 5 | 7,5 | 7,5 | 8,75 | |

| Shaft movement speed | m/min | 6 | 6 | 6 | 6 | |

| Suitable coil dimensions: |

|

|

| |||

| Max diameter | mm | 1800 | 2100 | 2100 | 2400 | |

| Max width | mm | 1600 | 1600 | 1800 | 2200 | |

| Min width | mm | 500 | 500 | 600 | 700 | |

| Central hole diameter min / max | mm | 400 / 700 | 400 / 700 | 400 / 700 | 400 / 700 | |

Company Details

Focusing on a customer-centric approach, BOFO SOLUTIONS has a pan-India presence and caters to a huge consumer base throughout the country. Buy Cranes in bulk from BOFO SOLUTIONS at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

20

Establishment

2009

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Pune, Maharashtra

Project Manager

Mr. Manish Palwe

Address

Flat No.6, Sneha Society, Chaphalkar Colony, Market yard Road, Pune, Maharashtra, 411037, India

coil grab in Pune

Report incorrect details