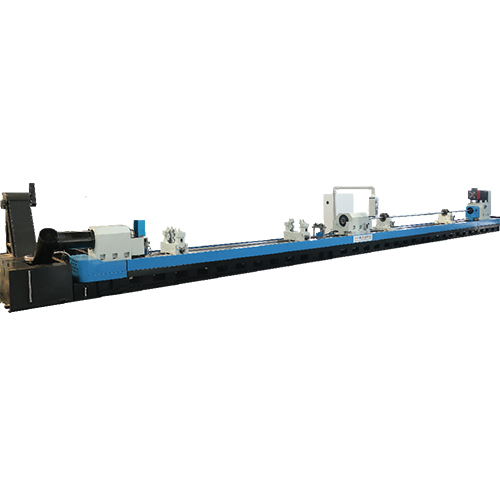

Cnc Deep Hole Skiving And Burnishing Machine - 250mm Boring Capacity, 12m Depth | High Efficiency, Intelligent Operation, Hydraulic Cylinder Precision

Price:

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Power Source | Electricity |

| Usage & Applications | Industrial |

| Payment Terms | Cash on Delivery (COD), Others |

| Delivery Time | 4-5 Days |

| Packaging Details | Standard |

| Main Domestic Market | All India |

Product Overview

Key Features

The machine uses fixed workpiece,tool rotates and feeds processing methods. The machine is equipped with a KND CNC system, and the boring box is driven by an AC servo spindle motor. The spindle bearing adopts high-precision bearings and has high rotation precision. The feed box adopts servo motor and stepless speed regulation. Equipped with high-precision ball screw for high-precision and stable feed of the spindle head. The bed is made of cast bed and linear guide rail with a width of 650mm. The linear guides ensure the overall rigidity and guiding accuracy of the machine. Dedicated hydraulic self-centering clamps ensure the stability of the workpiece during high-speed machining. The machine is equipped with automatic chip removal device and the coolant filtration method adopts three-stage filtration. It is a processing equipment specialized in manufacturing hydraulic cylinders, which is another major innovation in deep hole technology. The machine is equipped with high-efficiency automatic expansion and contraction skiving and burnishing tools (Germany made , Korea made , and China made ). It uses rough-skiving -burnishinging processing to process workpieces up to 6mm. The machine is equipped with a special hydraulic retracting tools system. The system pushes the core rod to make the diameter of the skiving insert and the roller smaller, the tool returns to the pressure head, and the hydraulic system pulls the core rod to return the tool to its original size. This machine is especially suitable for high-volume processing of various hydraulic cylinders and other precision pipe.

SPECIFICATION: TGK25

CAPACITY:

Boring diameter: I 250mm

Max. boring depth: 1-12m

Workpiece clamped dia. range: I 100mm a I 300mm

SPINDLE:

Height from spindle center to bed: 400mm

Spindle bore diameter: I 65mm

Taper of spindle bore: 85mm 1:20

Range of spindle speed: 40-1000r/min (two shifts, infinite)

FEEDS:

Feed speed range (infinite): 5-1000mm/min

Carriage rapid-moving speed: 3.5m/min

MOTORS:

Main motor power: 45KW/60KW

Hydraulic pump motor power: 2.2KW

Feed motor power: 7.5KW AC servo

Cool pump motor power: 7.5KW x 2

OTHERS:

Rated pressure of cooling system: 2.5Mpa (gear pump)

Flow volume of cooling system: 200L/min (two groups), 300L/min (two groups)

Rated working pressure of hydraulic system: 6.3Mpa

Max. axial force on pressure head: 68KN

Max. clamping force by pressure head on workpiece: 20KN

CNC:

Beijing KND or depending on client request

Company Details

Dezhou Sanjia Machine Manufacturing Co., Ltd., located in Dezhou Economic Development Zone, Shandong Province, designs, makes and sells general deep hole processing machine tools (including deep hole drilling machines, deep hole drilling and boring machines, and deep hole boring machines), as well as CNC deep hole drilling machines, CNC deep hole drilling and boring machines, and CNC deep hole powerful honing machines.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

60

Establishment

2003

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Dezhou, Shandong

Export Manager

Mr. Travis Zhou

Members since

2 Years

Address

No.7, Shanshui Street, Hengde Industry Park, Yunhe Area, Dezhou, Shandong, 253000, China

burnishing machine in Dezhou

Report incorrect details