Clc Blocks - Lightweight Cellular Concrete, 400-1800 Kg/m3 Density | Superior Thermal Insulation, Low Water Absorption, Versatile Applications

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Cement, sand, water, fly ash |

| Density | 400-1800 kg/m3 |

| Compressive strength | 65 kg/cm2 |

| Water absorption | 5-12% |

| Dimensions | Various |

| Shape | Rectangular |

| Color | Gray |

| Features | Lightweight, Durable, Thermal efficiency, Sound insulation, Easy to work, Cost effective |

Product Overview

Key Features

- It is feasible to produce this material in a wide range of controlled densities varying from 400 kg/m3 to 1,800 kg/m3. "AST Engineers" Generator ensure and accuracy of 5% in the target density.

- Diverse Applications of CLC: The lower density range of 400-600 kg/m3 is used as insulation over roofs or in cold storage or as filling in sunken areas of floors. The range of 800-1000 kg/m3 is good for making non load-bearing cladding panels or pre-cast blocks for nonstructural filler wall masonry. The density range of 1.200-1,800 kg/m3 (having 28-day cube crushing strength of 65 kg/cm2) is used in the form of structural elements-either as reinforced components or in the form of block-work for load bearing walling masonry.

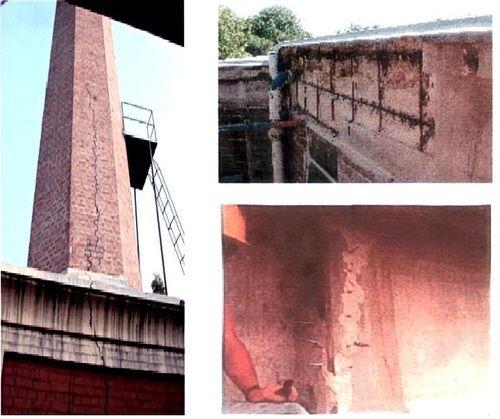

- As a consequence of closed cellular structure of the material, the water absorption of CLC is lower, being in the range of 5% to 12%, depending on density. This is much better than the water absorption of over 45% exhibited by the factory made. Autoclaved Aerated Blocks or 18% to 23% permissible for the light-weight aggregate blocks as per I.S. 2185 (Part II)-1989. In view of better resistance to water penetration, it is not obligatory to pre-coat steel bars in reinforces elements, which is mandatory for the aerated autoclaved version. A higher concrete cover, than specified for normal reinforced concrete is, however, recommended.

- Light-weight with superior thermal and sound insulation : This CLC is much lighter in weight than ordinary bricks or dense concrete blocks. This can result in substantial savings in structural and foundation costs of high rise structures, if walling masonry of bricks/concrete hollow blocks is substituted with CLC block masonry or panels. CLC is also four to five times more efficient thermally. Ease of working with CLC : CLC blocks can be sawn like timber. Cutting chases for electric conduits or water lines is very easy. In fact it can be done very fast with the help of chase-cutting machine. One can easily drive nails into CLC, just as in timber.

Company Details

Focusing on a customer-centric approach, AST ENGINEERS PVT. LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Get AAC Blocks from AST ENGINEERS PVT. LTD. at Trade India quality-assured services.

Business Type

Manufacturer, Service Provider, Supplier

Employee Count

50

Working Days

Monday To Sunday

GST NO

07AABCA4051F1Z6

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 07AABCA4051F1Z6

New Delhi, Delhi

Director

Mr. Vaibhav Kapani

Address

E-124, Greater Kailash-II, New Delhi, Delhi, 110048, India

Report incorrect details