Structural Waterproofing Application: Ac Drive

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Polymer-cement |

| Application | Coating |

| Thickness | 1-3 mm |

| Adhesion | Excellent |

| Flexibility | High |

| Usage | Basements, roofs, and other structures |

| Standards | ASTM C954 |

| Features | Waterproofing, Leak prevention, Durable, Long-lasting, Reliable |

Product Overview

Key Features

STRUCTURAL WATER PROOFING

Up until the development of modern waterproofing materials the only practical method of keeping a basement, dry was by providing external or internal sub-floor drainage. This system proved to be reasonably successful, but eventually it was found that these drains were vulnerable to silting up and blockage. More recently the modern methods of waterproofing basements have generally involved the application of a waterproofing material applied to the surface of the walls and floor to form a waterproof tank. Therefore modern Internal / External 'lining' systems had provided a promising solution.

Waterproofing system can be classified in Two Categories: Modern & Traditional

Modern Water-Proofing Systems

Coatings & Injection Grouting:

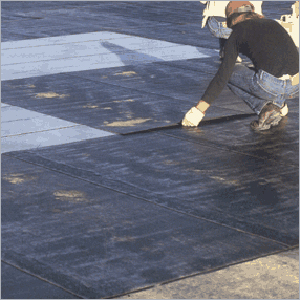

1. POLYMER CEMENTITIOUS COATINGS

There are also cementitious coatings available that consist of mixing a polymer with cement and applying on the surface. This gives a flexible membrane and use of fiber as an reinforcement gives very good results

.On un-stabilized surfaces are of no use. All product catalogues mention this by stating that the surface must be properly prepared without mentioning how. Obviously any surface where the product fails is as per the manufacturer a badly prepared .

2. PENETRATING COATINGS

The coatings that are most effective and can also act against water pressure are the penetrating coatings that are mineral based and have been in the market for more than fifteen years now. These have a crystalline action and penetrate the capillaries and form insoluble hard crystal in them and make the concrete or cementatious surfaces water tight. These are again to be used only as part of a complete systems in integral waterproofing and not as stand alone systems.

3. EPOXIES AND POLYURATHENES

Various membranes like epoxy and polyurethane are also used for waterproofing. These membranes also have excellent water repellant properties but are very difficult to apply and need very high standards of surface preparation to apply.

The membranes therefore face very high failure rates since they can peel off. and once they start peeling the whole membrane comes off. As it is all epoxies have very low adhesion unless the surfaces are well prepared.

4. PRESSURE INJECTION GROUTING

a. Soil (Cement Grout)

b. Concrete (Epoxy Grouting)

Traditional Water-Proofing Systems

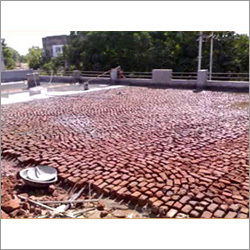

Brick bat coba :

This is a system used particularly for roofs in the coastal region and consists of putting brickbat on roofs to give a slope and then grouting the same with mortar admixed with various proprietary chemicals most in the nature of water proofing compounds. This is mostly finished with IPS topping with a tile pattern cut into the top to form crack inducer joints to prevent cracks from appearing. This has the advantage of providing an excellent slope so that the water drains away.

ADVANTAGES

1. PROVIDES SLOPE

The system provides an excellent slope for the water to drain away and since water does not accumulate there is no leakage. Also it has a certain water retaining capacity and water is absorbed by the brick when it rains and released when it stops. Of course overloading results in leakages

DISADVANTAGES

1. CRACKS DUE TO TEMPERATURE VARIATIONS

The brick bat coba treatment through successful in the damp heat of coastal regions cracks up completely on contact with the variations of temperature faced in North India between day and night temperature.

2. IMPOSES UNNECESSARY LOAD

This system has the disadvantage of imposing an unnecessary load on the system. Once cracks appear they are almost impossible to repair and water as in the case of the tar felting travels below the coba and exits wherever it finds a path. It is impossible to trace the inlet point let alone repair it.

3. ALMOST IMPOSSIBLE TO DISMANTLE FOR REPAIRS

Some parts of the coba stick so well to the concrete that even if an attempt is made to dismantle the system the slab gets damaged.

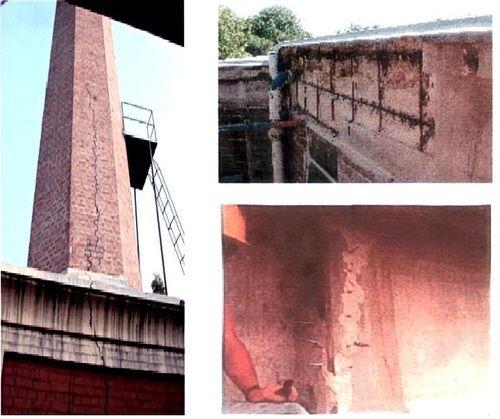

Stone Waterproofing

There are various forms of stone waterproofing systems in use. The kotastone system for instance consists of fixing stones on the walls or the underneath keep out the water in parts. The red sand stone system involves fixing Agra stone on the walls and pouring slurry into the joints and the areas between the walls and the stone.

ADVANTAGES

1. EASY TO INSTALL

The stone systems are easy to install and even ordinary masons with no knowledge of water proofing can install the same.

2. CAN BE USED ON WEAK STRUCTURES They are effective in the short run even if the structure is weak. In a basement with a single brick wall as retaining wall for instance, nothing will work as well in the short run as a stone system.

DISADVANTAGES

1. JOINTS FORM WEAK POINTS

Both these suffer from the weakness that they are as strong as their joints as they are not monolithic. If the joints fail the systems are bound to. When the Kota stone system for instance is used in basements then it has to be used on the lean concrete. After soil below the lean concrete expands on absorbing water during the monsoons and then contracts after losing water a void is created below the lean concrete and it sometimes collapses into the void. The stone waterproofing then being supported only on the joints collapses into the void and creates a major weak point.

Company Details

Focusing on a customer-centric approach, AST ENGINEERS PVT. LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Get Waterproofing Services from AST ENGINEERS PVT. LTD. at Trade India quality-assured services.

Business Type

Manufacturer, Service Provider, Supplier

Employee Count

50

Working Days

Monday To Sunday

GST NO

07AABCA4051F1Z6

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 07AABCA4051F1Z6

New Delhi, Delhi

Director

Mr. Vaibhav Kapani

Address

E-124, Greater Kailash-II, New Delhi, Delhi, 110048, India

Report incorrect details