Pressure Grouting Soil Stabilization

Price:

Get Latest Price

In Stock

Product Specifications

| Method | Cement mixing |

| Soil Types | Most types |

| Cement Ratio | 5-15% |

| Water Ratio | 1:1 to 1.5:1 |

| Strength Gain | 5-10x |

| Permeability | 5x10-7 cm/sec |

| Usage | Foundation support, liquefaction mitigation, retaining structures, waste containment |

| Features | Soil stabilization, Ground improvement, Cost-effective, Increased strength, Reduced permeability |

Product Overview

Key Features

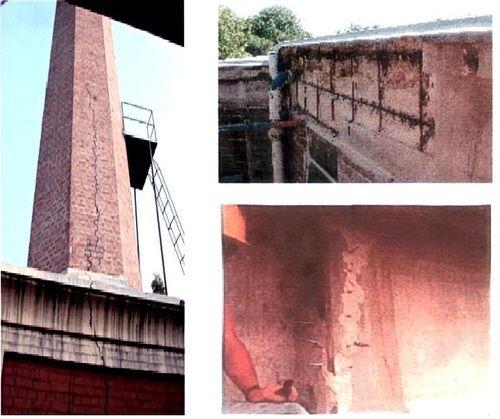

Cement Soil Mixing in Soft Ground

History:

Various methods of soil mixing, mechanical, hydraulic, with and without air, and combinations of both types have been used widely in Japan United States, India The soil mixing, ground modification technique, has been used for many diverse applications including building and bridge foundations, retaining structures, liquefaction mitigation, temporary support of excavation and water control. Names such as Jet Grouting, Soil Mixing, Cement Deep Mixing (CDM), Soil Mixed Wall (SMW), Geo-Jet, Deep Soil Mixing, (DSM), Hydra-Mech, Dry Jet Mixing (DJM), and Lime Columns are known to many. Each of these methods has the same basic root, finding the most efficient and economical method to mix cement (or in some cases fly ash or lime) with soil and cause the properties of the soil to become more like the properties of a soft rock.

Treated Soil Characteristics:

As stated, the intent of most soil mixing is to modify the soil so that it's properties become similar to that of a soft rock such as a clay shale or lightly cemented sandstone. The modulus of elasticity and unconfined compressive strengths are typically 1/5 to 1/10 that of normal concrete. Almost all soil types are amenable to treatment; however, soils containing more than 10% peat must be tested thoroughly prior to treatment. Mixing of soft, clay soils must be carefully controlled to avoid significant pockets of untreated soils. However, there are methods readily available to insure competent mixing and methods of testing to insure that adequate mixing and treatment has been achieved.

Soil mixing is also commonly used as a stabilization or in-situ fixation method for containing hazardous wastes and sludges. Containment walls can be constructed with permeability of approximately 5x10-7 cm/sec, similar to that achieved by most slurry wall techniques.

Quality Control and Testing

Since the aggregate being used in producing the engineered "low strength" concrete in situ is the native soils, pre-construction soil borings, testing of the mix design with the in-situ soils is a must. One to two cubic feet of the soils is sufficient to run the required laboratory, pre-production tests on the soil cement mix. Various water cement ratios are considered, usually between 1:1 and 1.5:1 (by weight). The amount of cement, again by weight, is typically 5-15% of the weight of the soil to be treated.

Proper injection of slurry, mixing and blending of the cement slurry and soil is verified by several means. Initially, during installation, wet grab samples are taken from different elevations in the mixed columns after the tools are withdrawn. Remote closing tubes are inserted, filled with the wet, mixed soil and slurry, a closure lid secured and the sample brought to the surface. The slurry is poured into cylinders for later laboratory testing. In addition, core sampling of the completed columns may be performed. It is wise to wait at least until 28 days after installation to perform coring, and then only with triple tube coring equipment, as the sample may be difficult to retrieve intact because of it's low strength.

Company Details

Focusing on a customer-centric approach, AST ENGINEERS PVT. LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Get Others from AST ENGINEERS PVT. LTD. at Trade India quality-assured services.

Business Type

Manufacturer, Service Provider, Supplier

Employee Count

50

Working Days

Monday To Sunday

GST NO

07AABCA4051F1Z6

More Product From This seller

Seller Details

GST - 07AABCA4051F1Z6

New Delhi, Delhi

Director

Mr. Vaibhav Kapani

Address

E-124, Greater Kailash-II, New Delhi, Delhi, 110048, India

Report incorrect details