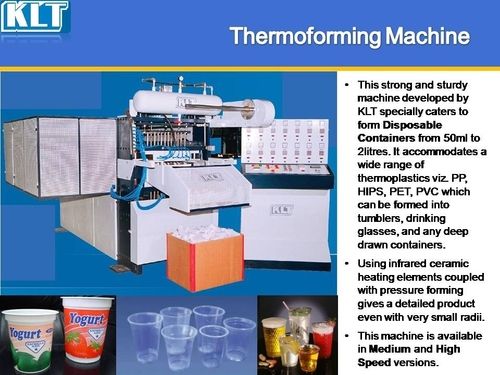

Automatic Vacuum Forming Machine - Processes Hips, Pvc, Ldpe Up To 3mm | Automatic Operation, Inline Cutting, Power Efficient, Uniform Thickness

Price:

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Material | Steel, Plastic |

| Dimensions | Variable |

| Power | Variable |

| Heating Element | Infrared Ceramic |

| Max Sheet Thickness | 3Mm |

| Suitable Material | Hips, Pvc, Ldpe, Eps |

| Control | Panel |

| Features | Easy Operation, Automatic Process, Uniform Thickness, Inline Cutting, Power Efficient, Versatile Forming |

| Payment Terms | Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cash Advance (CA) |

| Delivery Time | Mutually Discussed/ Months |

| Main Domestic Market | All India |

Product Overview

Key Features

SALIENT FEATURES

Very easy to Operate - Only one individual, can operate through a control panel which is separated from the machine.

Different of material such as HIPS, PVC, LDPE up to 3mm can be processed.

Automatic operation - All operations viz. roll feeding, forming, clamping, heating, loading, unloading are automatic.

Uniformity in thickness of the product obtained - Plug assist facilities is production of uniform thickness.

Inline cutting facility - It may be offered for vertical slitting and scrap disposal.

Power Efficient - A true infrared ceramic element ensures uniform heat distribution as well as considerable power saving. Sandwich heating facility is also available, specially for processing EPS material upto 3mm.

The application of this machine are as:

All Kinds of shapes can be formed by this machine.

Plastic things such as cosmetic trays, burger boxes, partition trays.

PACKING of capsules, tablets, vials, ampoules, trays, disposable syringes.

Plastic PACKING for batteries, pencils, toothbrushes, pens, cookies, cakes, blades etc.

Calculators and electronic products.

Spark plugs, gaskets, seals.

Company Details

Business Type

Manufacturer, Supplier

Employee Count

10

Establishment

1980

Working Days

Monday To Sunday

GST NO

07AABCK2558H1ZK

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 07AABCK2558H1ZK

New Delhi, Delhi

Manager

Mr M. K. Arora

Address

C-67/2, (Block-C), Okhla Industrial Area, Phase-2, Near Kalka Ji Mandir, New Delhi, Delhi, 110020, India

Report incorrect details