Automatic Electrically Control Moulding Machine

Price:

Get Latest Price

In Stock

Product Specifications

| Color | Grey |

| Injection Unit | Bp-60 |

| Clamping Force | 80 Tones |

| Motor Power | 10 Kw |

| Material | Steel |

| Dimensions | 14X4X6 Ft |

| Weight | 1.7 Tones |

| Features | Automatic Operation, Power Saving, Precise Control, Customizable, Durable Design, Easy Operation, High Efficiency, Cost Effective |

Product Overview

Key Features

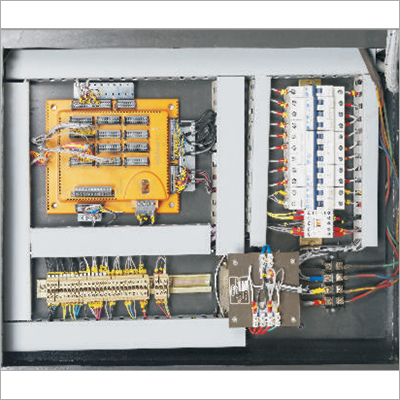

Fully Automatic Electrically Control Moulding Machine

Our company is reckoned for world class moulding machines. We are bringing forth Fully Automatic Electrically Controlled moulding machines that comprises control & timer with a shot counter. These machines are best suited for making household goods, spoons and bottle caps. These Fully Automatic Electrically Control moulding machines are designed keeping in mind the power saving factor. They are available at reasonable prices and can be customized as per the demands of the clients.

| Specifications: | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Standard Features: | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Optional Features: | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Company Details

Focusing on a customer-centric approach, BOMBAY PLASTIC MACHINERY has a pan-India presence and caters to a huge consumer base throughout the country. Buy Injection Moulding Machine in bulk from BOMBAY PLASTIC MACHINERY at Trade India quality-assured products.

Business Type

Manufacturer, Supplier

Employee Count

15

Establishment

1997

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Ludhiana, Punjab

Accepts only Domestic inquiries

Proprietor

Mr. Davinder Thapar

Address

3839, Opposite ITI College, Petrol Pump Street No.- 8, Gill Road, Ludhiana, Punjab, 141003, India

Report incorrect details