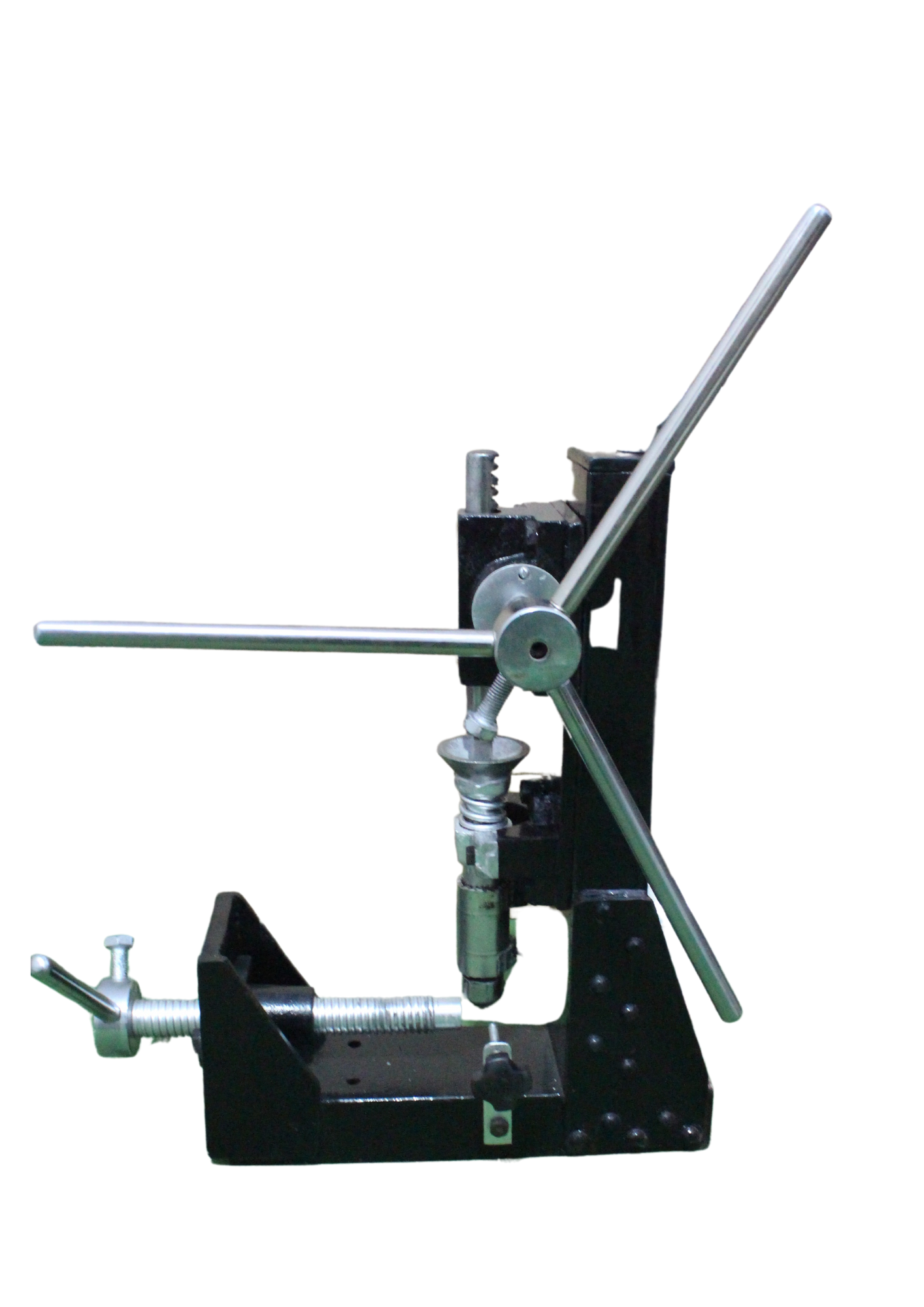

Semi Automatic Moulding Machine 40gram

Price: 84999.00 INR / Piece

(84999.00 INR + 0% GST)

Get Latest Price

MRP:

84999.00 INR / Piece

Weight :

124.00 Tonne

1 Pack Contains :

1

Minimum Pack Size :

1

In Stock

Product Specifications

| Product Type | Semi Automatic Moulding Machine 40Gram |

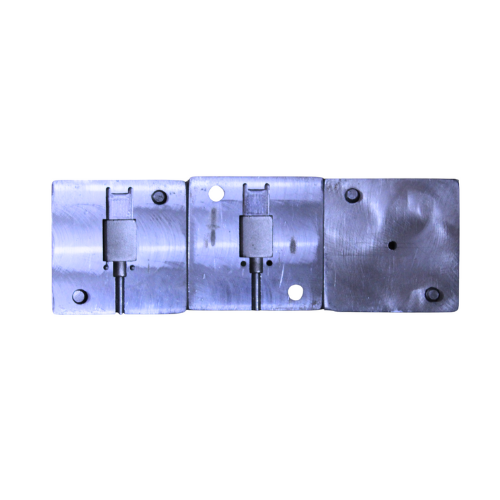

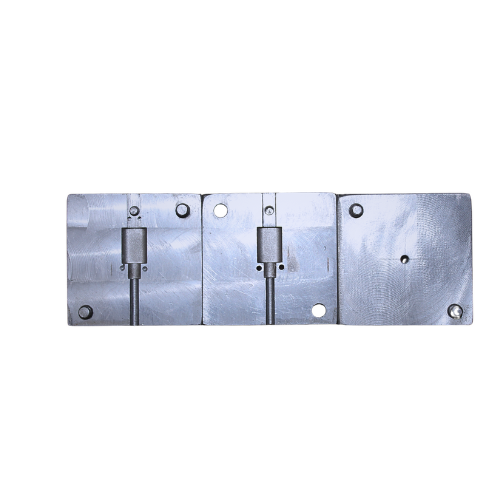

| General Use | Data Cable Manufacturing |

| Computerized | No |

| Automatic | No |

| Supply Ability | 100 Per Month |

| Delivery Time | 7 Days |

| Packaging Details | Industrial Standard |

| Main Domestic Market | All India |

| Currency | INR |

| Price Type | fixed |

| Returnable | No |

| MRP | 84999.00 INR |

| Weight | 124.00 Tonne |

| Stock Quantity | 11 |

| Price | 84999.00 INR (Approx.) |

| Shipping Type | order_percent |

| Unit Type | Piece/Pieces |

| Mop | 1 |

| Moq | 1 |

| Shipping Rate | 1.00 |

| Pkg Box Breadth | 20.00 in |

| Pkg Box Length | 45.00 in |

| Brand Name | APS STAR |

| Pkg Box Height | 28.00 in |

| Packsize | 1 |

| Product Unit | 1 Piece/Pieces |

| Minimum Ordered Packs | 1 |

| Minimum Order Quantity | 1 |

| GSTIN | 0% |

Product Overview

Key Features

Key Features and Description of a Semi-Molding Machine:

Operation Type :

Semi-Automatic Process : As the name suggests, semi-molding machines require some manual intervention during the molding process, though much of the work is automated. Operators may be responsible for loading materials, setting up molds, and removing finished products.

Unlike fully automated machines, where the entire process is controlled by a computer or robotic system, a semi-molding machine involves a mix of human and machine interaction, which allows for flexibility and control in the production process.

Molding Process :

Injection Molding : The machine injects molten material (typically plastic or rubber) into a mold under high pressure to form the desired shape. In semi-molding machines, the injection and curing cycles might be automated, but operators manually handle material loading, mold changes, and part removal.

Compression Molding : For materials that require heating and pressure to mold, the semi-molding machine compresses the material in the mold under controlled conditions, which may involve some manual adjustment.

Transfer Molding : Similar to injection molding but involves transferring the material from one part of the mold to another. It also requires some manual input in terms of material loading.

Materials Used :

Plastics : Common materials used in semi-molding machines include thermoplastics (such as ABS, PVC, PE, etc.) and thermosetting plastics.

Rubber : Used for molding parts like seals, gaskets, and automotive components.

Metal Alloys : In some cases, metals like aluminum can be used for die-casting processes in semi-molding machines.

Composites : Some semi-molding machines are used for molding composite materials such as fiberglass-reinforced polymers.

Flexibility and Customization :

Semi-molding machines are often more flexible than fully automated machines, allowing for quick changes in production runs. This is useful when small batches or custom orders are required.

Manual Adjustments : Operators can adjust molding parameters like pressure, temperature, and time to ensure the quality of the molded parts.

Mold Design :

Interchangeable Molds : Semi-molding machines often have interchangeable molds, which allows them to create a variety of shapes and sizes. The operator typically installs or changes the mold based on the product being manufactured.

Multi-Cavity Molds : Many semi-molding machines use molds with multiple cavities to increase productivity by producing more parts in each cycle.

Molding Cycle :

Manual Material Loading : The operator manually places the material (plastic pellets, rubber, etc.) into the machine or mold.

Automatic Injection/Compression : Once the material is loaded, the machine automatically handles the injection or compression process, applying pressure and temperature as needed.

Company Details

Focusing on a customer-centric approach, APS STAR has a pan-India presence and caters to a huge consumer base throughout the country. Buy Blow Moulding Machines in bulk from APS STAR at Trade India quality-assured products.

Business Type

Manufacturer, Supplier

Employee Count

10

Establishment

2016

Working Days

Monday To Sunday

GST NO

07FKWPK0390E2ZT

Payment Mode

Cash on Delivery (COD)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 07FKWPK0390E2ZT

New Delhi, Delhi

Sales Head

Mr. Aps Star Mobile Charger

Members since

2 Years

Address

Plot No. -175, Karan Vihar, Near Fauji Chowk, Nangloi, New Delhi, Delhi, 110086, India

Report incorrect details