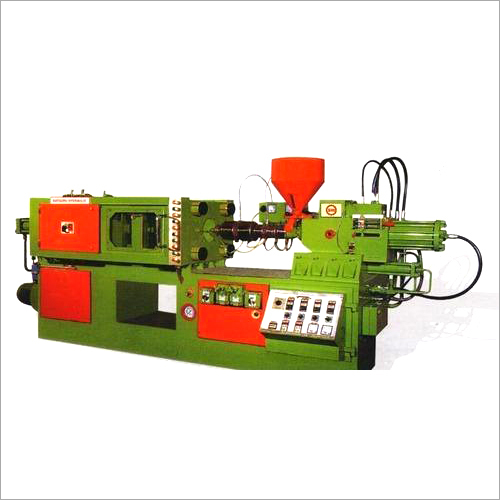

Electrical Injection Moulding Machine - Maximum Injection Force Of 750 Tons, Digital Display Timer & Pyrometer, Automatic With Data Lock Feature, High Efficiency Heat Exchanger, Compact Power Panel, Suitable For Various Industries

Price:

Get Latest Price

In Stock

Product Specifications

| Injection Unit | Bp-130 |

| Screw Diameter | 46-50 Mm |

| Max. Shot Weight | 300-325 Gms |

| Screw Stroke | 205 Mm |

| Plastising Capacity | 20 G/S |

| Injection Force | 4.3 Tones |

| Clamping Force | 130 Tones |

| Features | Automatic Operation, Data Lock Function, High Efficiency, Precise Control, Durable Materials, Easy Operation, Versatile Use, Cost Effective |

Product Overview

Key Features

We

are a leading manufacturer and supplier of optimum quality Electrical

Injection Moulding Machine.

Our provided machine is extensively used for used

in various industries such as automobile, power plant, steel,

extrusion and various others industries.

This

machine is automatic with a data lock function to prevent

unauthorized access and mistaken amendments. The

offered machine is manufactured with the help of cutting-edge

technology by making use of fine grade components under the stern

guidance of our team of professionals at our well-equipped production

unit. Moreover, this Electrical

Injection Moulding is

available in different technical specifications to meet the specific

requirements of clients.

Features:

Centralized

lubrication systems

Cold

Start screw protection

Compact

Power Panel

Digital

display timer & pyrometer

Direct

hydraulic screw drive

Gas

nitrided steels screw barrel and cavity

Hard

chrome plated and tie bars

High

efficiency heat exchanger

Larger

Opening stroke mould capacity & tie bar distance to accommodate

large moulds

Mechanical

ejector

Shot

Counter

Suck

back systems after charging

Time

control for recycle

Additional

features:

Core

pulling attachment

Hopper

dryer

Hydraulic

door safety

Hydraulic

ejector

Motorized

mould height setting

PLC

Micro processor & proportional hydraulic systems

Other Information:

We are manufacturing and exporting the world class Electrically Controlled Fully Automatic Moulding Machines. Our completely automatic machines are provided with a data lock function to prevent unauthorized access and mistaken amendments. These Electrically Controlled Fully Automatic machines designed by us facilitates faster and rapid production of plastic products without any flaw and defects. These machines are available at nominal prices and we ensure our clients a timely delivery.

| Specifications: | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Company Details

Focusing on a customer-centric approach, BOMBAY PLASTIC MACHINERY has a pan-India presence and caters to a huge consumer base throughout the country. Buy Injection Moulding Machine in bulk from BOMBAY PLASTIC MACHINERY at Trade India quality-assured products.

Business Type

Manufacturer, Supplier

Employee Count

15

Establishment

1997

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Ludhiana, Punjab

Accepts only Domestic inquiries

Proprietor

Mr. Davinder Thapar

Address

3839, Opposite ITI College, Petrol Pump Street No.- 8, Gill Road, Ludhiana, Punjab, 141003, India

plastic injection moulding machine in Ludhiana

Report incorrect details