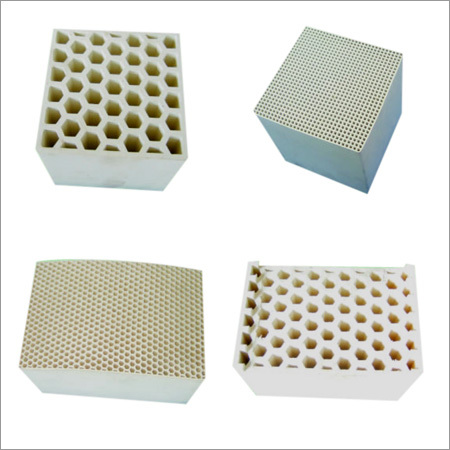

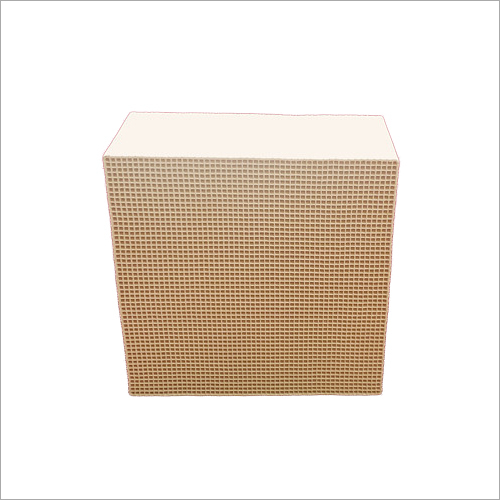

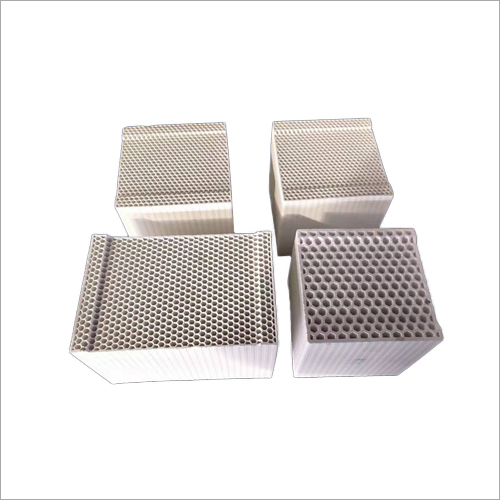

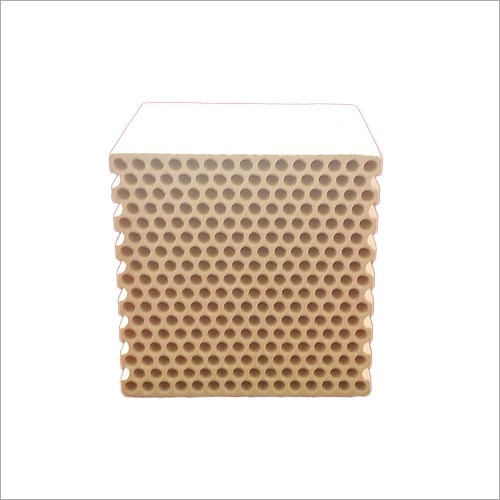

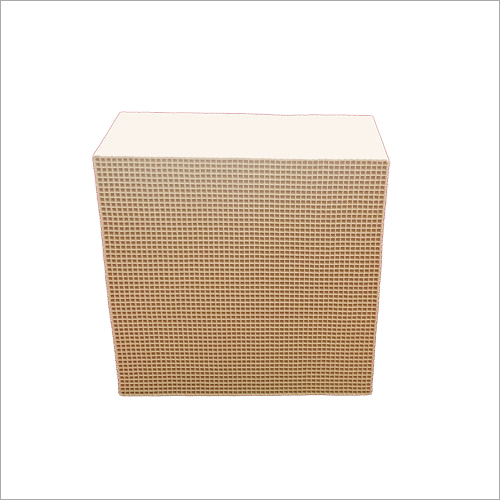

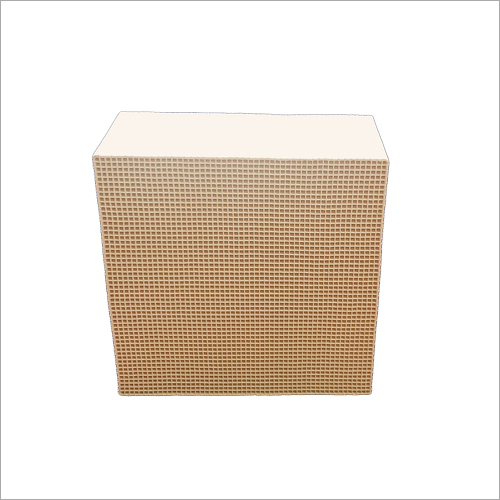

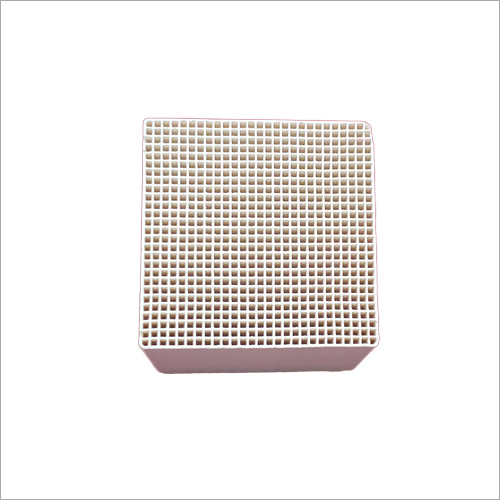

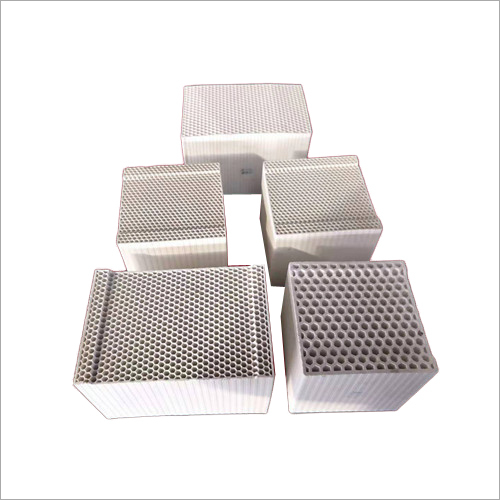

Application Of Honeycomb Ceramic Regenerator In Htac Application: Filter For Casting

Price Trend: 1.00 - 5.00 USD / Piece

Get Latest Price

Minimum Order Quantity :

3000 Piece

Brand Name :

Sf

In Stock

Product Specifications

| Filter Media | Other |

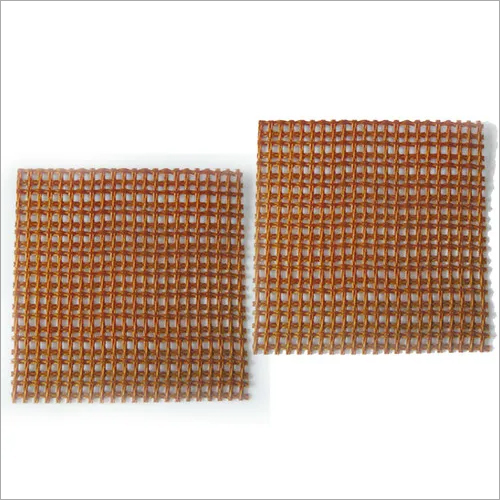

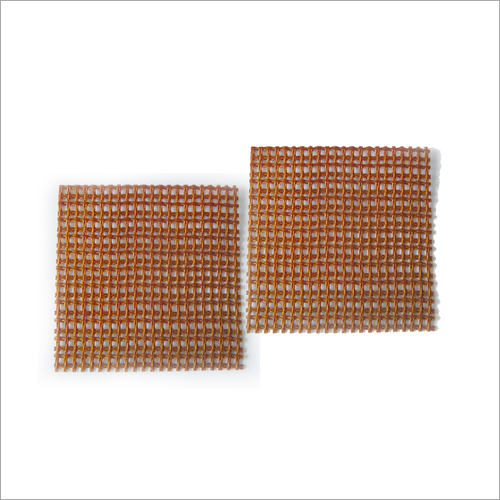

| Pore Size | 100-300csi |

| Size | 150 |

| Pressure | 1.2 mpa |

| Width | 150 Millimeter (mm) |

| Color | yellow ,white |

| Usage | Put the product into environment protection equipment |

| Inlet Diameter | 150 Millimeter (mm) |

| Weight | 8000 Grams (g) |

| Filter Rating | 2-45kg/s |

| Height | 300 Millimeter (mm) |

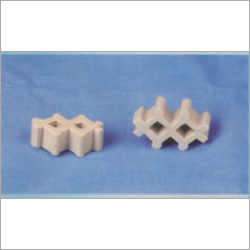

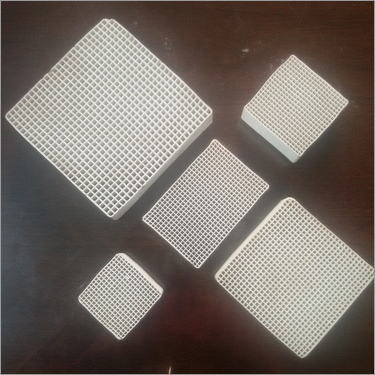

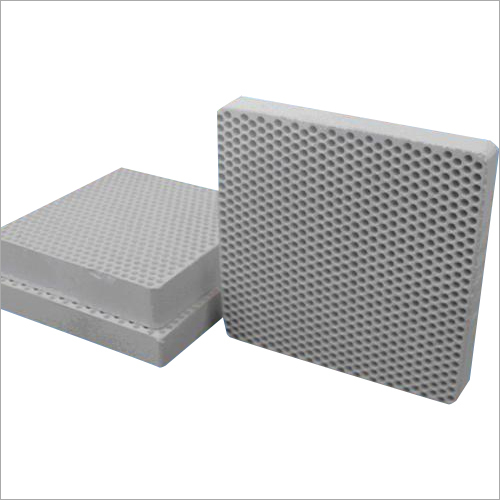

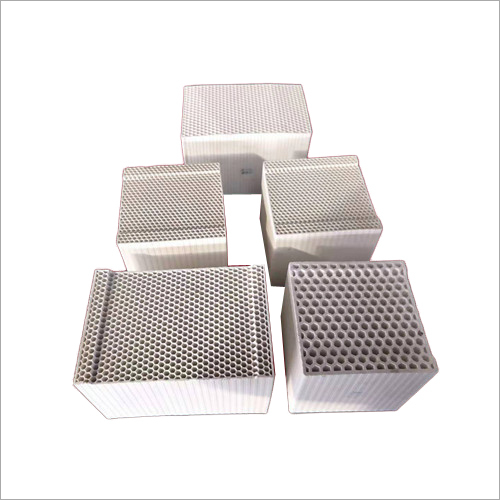

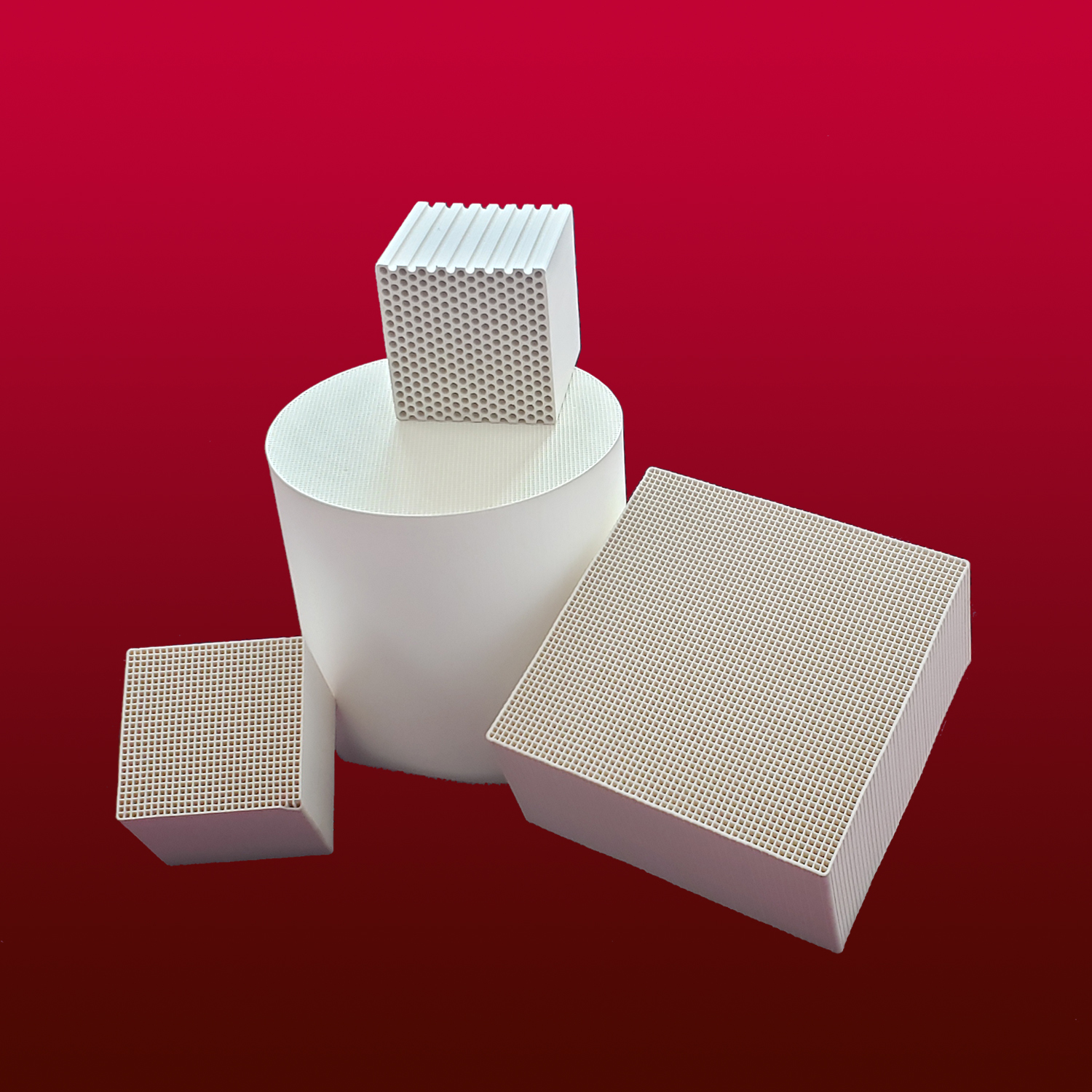

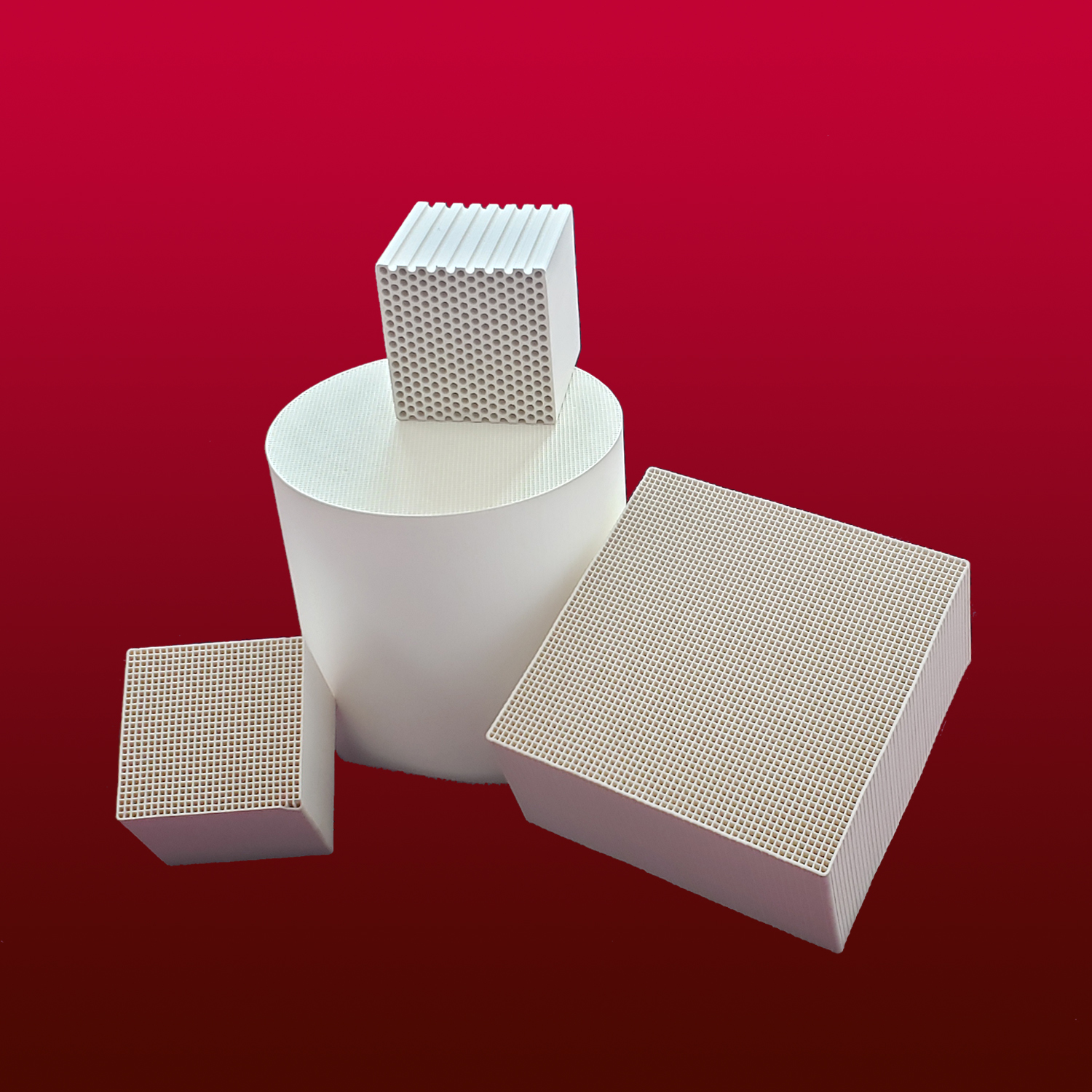

| Shape | Round ,square ,custom geometric shapes |

| Length | 150 Millimeter (mm) |

| Product Type | mass production |

| Outlet Diameter | 150 Millimeter (mm) |

| Material | Other |

| Type | Industrial Depth Filter Cartridge |

| Cartridge Style | Double Open End |

| Diameter | 150 Millimeter (mm) |

| Efficiency | 80-90% |

| Application | filter for casting |

| Warranty | Three years |

| FOB Port | TIANJIN SHANGHANG ,CHINA |

| Payment Terms | Letter of Credit (L/C), Telegraphic Transfer (T/T), Western Union, Letter of Credit at Sight (Sight L/C), Delivery Point (DP), Days after Acceptance (DA) |

| Supply Ability | 400000 Per Year |

| Delivery Time | 15-25 Days |

| Sample Available | Yes |

| Sample Policy | Sample costs shipping and taxes has to be paid by the buyer |

| Packaging Details | cartons and pallet |

| Main Export Market(s) | Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia |

| Main Domestic Market | All India |

| Certifications | Features:*Reduce NOx by avoiding high peak temperature*Reduce carbon dioxideReduced fuel consumption and reduced CO2 emissions*Energy savingHeat energy from exhaust gas used to heat combustion airFlame produces higher heat flux* Reduced equipment sizeUniform heat flux distribution and uniformity of thermal fieldThe combustion chamber volume is fullChemical & Physical Analysis:Name Alumina DenseCordierite PorousCordierite DenseAlumina Mullite CorundummulliteDensity(g/cm3) 2.0~2.3 2.1 ~2.5 1.7 ~2.0 2.4 ~2.7 2.0 ~2.5 2.3 ~2.7Coefficient of heat expansion(A--10-6K-1) (20~800AoC) a%0$?5 a%0$?3.5 a%0$?3.0 a%0$?5 a%0$?5 a%0$?6Specific Heat (J/Kg.K)(20~1000AoC) 900-1150 900-1100 900-1150 1000-1150 1000-1150 1100-1300Thermal Conductivity (W/m.k)(20~1000AoC) 1.5-2.0 1.5-2.5 1.2-1.8 1.5-2.5 1.5-2.0 1.5-2.5Impact Thermal Resistance(AoC/min) a%0Y=450 a%0Y=500 a%0Y=500 a%0Y=450 a%0Y=500 a%0Y=450Max. Working Tem.(AoC) 1350 1320 1320 1350 1450 1550Water absorption(%) 15-25 a%0$?1 15-25 a%0$?1 15-25 15-25Compressive strength(MPa) A axis a%0Y=32 a%0Y=29 a%0Y=34 a%0Y=36 a%0Y=28 a%0Y=39 B axis a%0Y=8 a%0Y=6 a%0Y=8 a%0Y=8 a%0Y=8 a%0Y=10Chemical composition(%) Al2O3 55-65 25-38 28-38 55-65 60-70 70-80 SiO2 25-35 50-60 45-55 25-35 25-35 15-25 MgO 1-3 5-10 12-14 3-5 0-1 0-2 others <5 <5 <5 <5 <5 <5Available sizes for honeycomb ceramic(mm) Quantity ofchannels Wallthickness ChannelWidth Surfacearea Voidsection Packagingdensity Weightper piece150A--150A--300 25x25 1.0mm 4.96mm 580m2/m3 68% 696kg/m3 4.7kg150A--150A--300 40x40 0.7mm 3.03mm 891m2/m3 65% 814kg/m3 5.5kg150A--150A--300 50x50 0.6mm 2.39mm 1090m2/m3 63% 903kg/m3 6.1kg150A--150A--300 60x60 0.5mm 1.99mm 1303m2/m3 63% 932kg/m3 6.3kg150x100x100 40x40 1mm 2.5mm 784m2/m3 49% 799kg/m3 1.2kg150x100x100 33x33 1.1mm 3.0mm 691m2/m3 52% 750kg/m3 1.13kg150x100x100 20x20 2.0mm 5.0mm 392m2/m3 49% 692kg/m3 1.04kg100x100x100 40x40 1.0mm 2.5mm 784m2/m3 49% 810kg/m3 0.81kg100x100x100 33x33 1.1mm 3.0mm 691m2/m3 52% 750kg/m3 0.75kg100x100x100 20x20 2.0mm 5.0mm 392m2/m3 49% 680kg/m3 0.68kgOther shapes, size, specification and material are available. |

Product Overview

Key Features

Company Details

Business Type

Exporter, Importer, Manufacturer, Supplier

Employee Count

300

Establishment

2013

Working Days

Monday To Friday

Payment Mode

Telegraphic Transfer (T/T)

Certification

ISO 9001:2015

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Cangzhou, Hebei

Sales Manager

Ms Kerry

Address

Guanting Industrial Park, Cangzhou City, Hebei Province China, Cangzhou, Hebei, 061034, China

ceramic honeycomb in Cangzhou

Report incorrect details