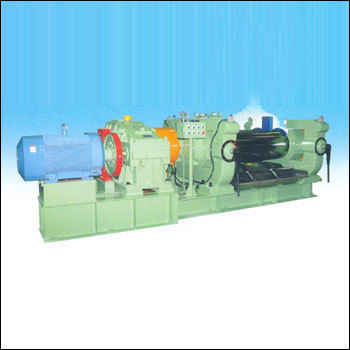

3000 Ltrs Capacity Basket Mill

Price:

Get Latest Price

In Stock

Product Specifications

| Capacity | 50-75 Kgs/Hr |

| Motor | One Hp Hydraulic |

| Warranty | 1 Year |

| Power | 240V Single Phaser |

| Material | Stainless Steel & Ms |

| Dies | 3 Die Set Free |

| Color | Blue |

| Features | Automatic, High Output, Durable, Easy Use, Low Maintenance, Efficient, Optimal Performance |

Product Overview

Key Features

The Basket Mill is an exceptionally versatile dispersion system that can be applied to a wide range of processing industries. Offering the very highest degree of efficiency and dependability, the ring mill is specifically engineered to allow complete mixing and dispersing in a single tank. From dry pigment addition

to dispersion to let- down ... all can be fully accomplished without tank

or blade changes, without time consuming clean-ups and without operator interaction.

Now high efficiency is simplicity itself.

The Basket Mill has redefined batch dispersion systems. This design insures that your materials pass through the high-density dispersion zone within the milling chamber at a high frequency. This system offers a high degree of dispersion, which can be many times more efficiency, is achieved without pipes, pumps or material transfer. The simplicity of the Mill system allows for very high material yields from batch to batch, as high as 99%. This means less clean-up and a reduction in waste solvents. Premixing, dispersion, compounding and dilution are all accomplished in a single unit that requires less space, less time and less energy to achieve bigger results.

ADVANTAGES:

a cClosed bottom on media vessel eliminates bypassing and inconsistent dispersion.

a cSeparate variable speed drives provide exceptional flexibility in mixing and dispersion.

a cBecause material flow is created by vortex action and centrifugal force, media over-flow into the batch is eliminated.

a cImpellers provide even circulation, ensure uniform dispersion, and allow a wider range of processing viscosities.

a cImpellers are mounted on independent shafts and feature a separate variable speed drive.

a cOperating speeds may be controlled manually or through an automated process controller.

a cThe sidewalls and bottom of the processing tank are jacketed along with the top of the ring mill dispersion vessel for efficient control of product temperature.

a cPortable tank with non-sparking caster provides mobility for packaging or cleaning.

a cClean up and product changeover is accomplished in less than 30 minutes on most products.

Company Details

Business Type

Exporter, Manufacturer, Supplier

Employee Count

15

Establishment

1973

Working Days

Monday To Sunday

GST NO

27ARUPS7370Q1ZE

Certification

ISO 9001 : 2015

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 27ARUPS7370Q1ZE

Mira Bhayandar, Maharashtra

Proprietor

Mr Fayazulla Z. Sayed

Members since

21 Years

Address

SHANTA INDL. ESTATE, SHED NO-1, BEHIND DODHIA PETROL PUMP, W.E. HIGHWAY, KASHIMIRA-MIRA ROAD, Mira Bhayandar, Maharashtra, 401104, India

grinding equipments in Mira Bhayandar

Report incorrect details