- Tradeindia

- Construction Machinery

- Wet Mix Paver Finisher

Wet Mix Paver Finisher

(53 products)Semi-Automatic Wet Mix Paver Finisher

Price: 2200000 INR/Set

MOQ1 Set/Sets

ColorYellow

TypePavers

Capacity150 to 200 tons/hour Ton/day

Kesar Road Equipments ( India ) Pvt. Ltd.

Mehsana

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller13 Years

Paver Finisher

Price Trend: 100000.00 - 1000000.00 INR/Piece

MOQ1 Piece/Pieces

Supply Ability10 Per Day

Delivery Time1 Week

Kaushik Engineering Works

Ahmedabad

Trusted Seller

Trusted Seller17 Years

Super Seller

Super SellerPaver Finisher Construction By Speedcrafts Private Limited

Price Trend: 2400000.00 - 3000000.00 INR/Unit

MOQ1 Unit/Units

Product TypePaver Finisher

General UseConstruction, Industrial

MaterialMetal, Other

Speedcrafts Private Limited

Patna

Trusted Seller

Trusted Seller4 Years

Super Seller

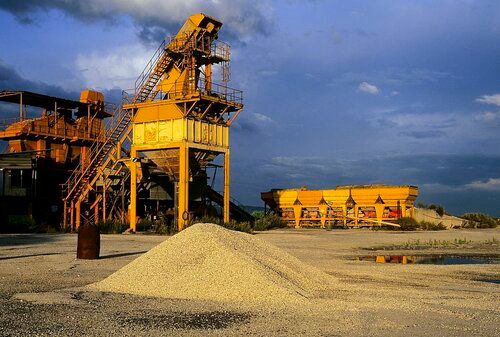

Super SellerYellow Asphalt Cum Wet Mix Paver Finisher

Price: 2300000 INR/Unit

MOQ1 Unit/Units

ColorYellow

Product TypeAsphalt Cum Wet Mix Paver Finisher

General UseRoad Construction

Automatic Hydrostatic Paver Finishers

Price: 2350000 INR/Piece

MOQ1 Piece/Pieces

ColorYellow

MaterialMild steel

Automatic GradeAutomatic

Wet Mix Paver Finisher In Delhi Sk Engineering, Material: Mild Steel

Product DescriptionWet Mix Paver Finisher In Delhi Sk Engineering

Wet Mix Paver Machine For Road Construction - Feature: User Friendly

Price: 2500000 INR/Unit

MOQ1 Unit/Units

Product TypeWet Mix Paver

General UseRoad Construction

MaterialSteel

Jay Khodiyar Metal Industries

Ahmedabad

Trusted Seller

Trusted Seller3 Years

Premium Seller

Premium SellerAutomatic Sensor Paver

Price: 2000000.00 INR/Unit

MOQ1 Unit/Units

ColorYellow

MaterialMS

ComputerizedNo

Road Paver Finisher - Automatic Grade: Manual

Price: 2200000 INR/Unit

MOQ1 Unit/Units

ColorYellow

MaterialMild steel

ComputerizedNo

Accel Infratech India Private Limited

Kolkata

Trusted Seller

Trusted Seller1 Years

Premium Seller

Premium SellerAutomatic Wet Mix Paver Finisher

Price: 1600000 INR/Unit

MOQ1 Unit/Units

ColorYellow & Black

MaterialSS

ComputerizedNo

Wet Mix Paver Finisher

Product DescriptionBacked by a capable team of experts, we have been able to manufacture, export and supply supreme quality Wet Mix Paver Finisher in Mehsana, Gujarat, India, which is basically used for road construction. The finisher provided by us is manufactured at well-developed production unit, equipped with all

Himalaya Engineering Co.

Mehsana

Trusted Seller

Trusted Seller19 Years

Premium Seller

Premium SellerMs Wet Mix Paver Finisher - Automatic Grade: Semi-Automatic

Price: 1850000 INR/Unit

MOQ1 Unit/Units

TypeRoad Marking Machines

General UseIndustrial

MaterialSteel

Top Rated Products

FAQs Related to Wet Mix Paver Finisher

The following advice will help you select the best wet mix paver finisher for your paving project:

● Establish the project's size

● Analyse the terrain

● Pavement thickness required

● Search for adaptability

● Verify the simplicity of upkeep

● Budget

For paving roads and highways, two separate types of heavy equipment are used: wet-mix paver finishers and dry-mix paver finishers. The method used to combine the cement, water, and aggregates is the main distinction between them.

Before being fed into the distribution auger, the aggregates, cement, and water are combined to create a wet mix in a wet mix paver finisher. The screed is then used to spread this wet mixture throughout the area to be laid and compress it.

The aggregates and cement, on the other hand, are combined in a separate mixer and then supplied into the paver's hopper in a dry mix paver finisher.

The kind of surface that each type of paver may be used on is another important distinction between the two types of pavers. Dry mix paver finishers are frequently used for smaller projects like parking lots and driveways, while wet mix paver finishers are better suited for big projects like motorways and runways.

Semi-Automatic Wm-6 Hes Wet Mix Paver Finisher

Price: 1850000 INR/Unit

MOQ1 Unit/Units

MaterialStainless Steel

ComputerizedNo

Automatic GradeSemi-Automatic

Semi-Automatic Wet Mix Paver Finisher

Price: 1950000 INR/Unit

MOQ1 Unit/Units

ColorBlack and White

TypePavers

MaterialStainless Steel

Asphalt Cum Wet Mix Paver Finisher

Product DescriptionWith the consistent focus on our quality, we offer a high quality Asphalt Cum Wet Mix Paver Finishers, which are processed under the supervision of our highly experienced professionals. The professionals of our team follow the ethical business policies and perform transparency in all our business de

Asphalt Cum Wet Mix Paver Finisher With Telescopic Screed

Product DescriptionWe are offering a precision-engineered range of Asphalt Cum Wet Mix Paver Finisher With Telescopic Screed. These wet mix paver finishers are used for laying wet mix and dry lean concrete in line and are demanded in the global market as these have accurate:\015\012* Paving Thickness\015\012* Paving

Wet Mix Paver

Price Trend: 38.00 - 90.00 INR/Piece

MOQ1 Piece/Pieces

MaterialMild Steel

Automatic Aspahlt Paver

Price: 1 USD ($)/Unit

MOQ1 Unit/Units

TypePavers

MaterialAsphalt

Capacity900Ton/Hr Kg/hr

Wet Mix Paver Finisher

Product DescriptionRiding on unfathomable volumes of industrial expertise, we are engaged in manufacturing and supplying a wide range of Wet Mix Paver Finisher in Mehsana, Gujarat, India. Precisely designed, offered paver finisher is manufactured using premium quality raw material and updated technology in adherence

Wet Mix Paver Finisher

Payment TermsDelivery Point (DP), Days after Acceptance (DA), Cheque

Sample AvailableYes

Sample PolicyContact us for information regarding our sample policy

Wet Mix Paver Finisher

Product DescriptionWe are engaged in exporting, manufacturing, supplying and trading of Wet Mix Paver Finisher in Mehsana, Gujarat, India. This finisher provides a perfect solution for dry lean concrete in line & laying wet mix macadam &. The offered paver finisher is manufactured using high grade material and advance

Yellow Wet Mix Paver Finisher Machine With Power Steering 4 Cubic Meter Hopper Capacity

MOQ1 Piece/Pieces

Product TypeWet Mix Paver Finisher Machine

MaterialSteel

ComputerizedNo

Concrete Lining Paver Finisher

Product DescriptionWe are manufacturing an supplying a vast range of Concrete Lining Paver Finishers find their application for rapid finishing which is used for avoiding traffic problems as per M.O.R.T.H. specification. We provide these finisher with brake used for effective breaking, hydraulically driven vibrating

Wet Mix Paver Finisher

Product DescriptionTo meet the various requirements of the customers, we are involved in manufacturing and supplying a wide assortment of Wet Mix Paver Finisher in Coimbatore, Tamil Nadu, India. Offered range of Wet Mix Paver Finisher is designed and made matching to set industry criteria. The offered method made from

More details...

Latest from Wet Mix Paver Finisher

Wet Mix Paver Finisher

By:

Unipave Engineering Products

Wet Mix Paver Finisher In Delhi Sk Engineering

By:

S K Engineering

Road Paver Finisher Machine For Road Construction Usage, 220-240v

By:

Vishwas Equipment

Wet Mix Paver Finisher Machine

By:

Jay Khodiyar Metal Industries

Wet Mix Paver Finisher

By:

Perfect Engineers

What is a wet mix paver finisher?

An essential piece of machine is a wet mix paver finisher. When constructing roads, parking lots, freeways and airport runways, it is used to lay down asphalt or concrete pavement. Complex procedures are used in the machine's working principles to guarantee a flat and smooth surface. Professional operators control the machine's speed as well as the pavement's thickness and slope, in order to ensure a smooth surface.

Working Principles of Wet Mix Paver Finisher

The wet mix paver finisher's operating principles include numerous crucial processes that guarantee a road or pavement's effective construction.

A hopper, conveyor system, and screed are all part of it. The water and asphalt mix is fed into the hopper and combined to create a slurry, which is then applied to the screed via the conveyor system. The screed, which is height- and angle-adjustable, regulates the asphalt layer's thickness and width while also heating and vibrating the asphalt as it is being laid. The surface is then further smoothed and compacted with a roller.

Features and Components of Wet Mix Paver Finisher

The capacity to handle enormous amounts of material, which minimises the need for regular reloading, is one of the primary features of wet mix paver finisher. Additionally, it includes an adjustable screed that enables the operator to regulate the pavement's thickness and slope, guaranteeing that the finished surface satisfies all prerequisites. Additionally, the machine features augers that evenly disperse the mix across its breadth. By doing this, it is made sure that the pavement is even and devoid of flaws. The hopper, conveyor system, screed, augers, and operator's platform make up a wet mix paver finisher.

Applications of Wet Mix Paver Finisher

The operator can construct a solid foundation for the road surface with the aid of this equipment. A homogenous mixture can be made by mixing the concrete and aggregates in the proper ratio using the wet mix paver finisher. It then uses a vibrating screed to spread this mixture uniformly and level it, creating a flat surface. As it makes a strong and lasting base that can support huge loads, this equipment is very helpful for constructing high-traffic roads.

Advantages of Using Wet Mix Paver Finisher

There are multiple advantages of using a wet mix paver finisher. It initially offers great compression, producing a surface that is more resilient and long-lasting. Secondly, it permits an even distribution of the mix, resulting in fewer weak spots or regions vulnerable to breaking. The wet mix paver finisher is additionally very effective and can swiftly cover a big area, conserving time and money. An additional advantage is that because the concrete is created and laid in a closed system, there will be less dust and air pollution at the construction site.

What is the use of a wet mix paver finisher?

This machine's main function is to lay down a solid and long-lasting foundation for road surfaces. Concrete and aggregates can be combined by wet mix paver finishers in the ideal ratios to produce a homogenous mixture. In addition to this, high-traffic roads, highways, and airport runway construction all benefit greatly from the usage of wet mix paver finishers.

What are the different types of wet mix paver finishers available in the market?

a The mechanical wet mix paver finisher is one of the more well-liked types. It features a mechanical transmission system that powers the augers and the conveyor belts.

a The hydrostatic wet mix paver finisher is another type. It runs on a hydraulic system. This machine makes pavement operations easier and more exact, which makes it perfect for tasks that call for an elevated level of precision.

a Self-propelled wet mix paver finisher is another option. As it is able to move and pave at the same time, it is perfect for big projects.

a Mini wet mix paver finisher is another popular type that is lighter and is employed for modest-sized projects.

What safety measures should be taken when operating a wet mix paver finisher?

First and foremost, it is important to ensure that each operator on the job site wears the proper personal protection gear, such as helmets, safety goggles, earplugs, and high-visibility clothes. Keeping an appropriate distance from the machine's moving components, like the augers and conveyor belts, is additionally crucial. To make sure the machine is in outstanding operating order, regular checks for maintenance must be performed, and any issues must be fixed right away. Operators have to inspect the area for barriers and debris before operating the machine in order to make sure the paving operation won't be affected. It is essential for keeping the machine running at an appropriate pace and to prevent overloading it.

Client Testimonials & Reviews

PrashantChougule

FORCE ENGINEERING

The service provided by TradeIndia is prompt. They proactively resolve your issues and help us grow business faster.

MahendraSaini

Om Shree Engineering Works

Tradeindia is providing us with good services. Promotion is good and we got genuine inquiries.

AmitPanchal

GAYATRI ENGIMECH PVT. LTD.

Our company has been a member of tradeindia from 2013. We are happy with the service provided by tradeindia to promote our products to our clients all over the world. It has helped us to increase our visibility. The team tradeindia are also constantly interacting with us to help and improve our online marketing.

AjaySavaliya

BALAJI CONSTRUCTION MACHINERY

We are glad to receive prompt and effective timely services from you. We appreciate the effort of your executive Mr. Ankit Tilva, he is dynamic and every enthusiastic. He helped us to promote our business on tradeindia. His wide expertise and knowledge on internet marketing, had boost our sales up to few percentage. We hope for continuous and effective service from company as today, Mr. Ankit is providing. Thank you for your cooperation.

BhushanDaftari

BUILDQUICK MACHINERY COMPANY

We really appreciate the service of tradeindia and shall continue using for the next 3 years due to great relationship building by Tradeindia Regional Manager.

SasidharanGovindan

SABIN ENTERPRISES

We are with tradeindia for more than 15 years and tradeindia services are very good and we get inquiries also. but we need only overseas inquiries and shall much appreciate to receive good inquiries for a long time to come. we are happy with their servicesA

Wet Mix Paver Finisher Price List

Product Name | Expected Price |

|---|---|

| Asphalt Cum Wet Mix Paver Finisher | 2300000 |

| Cum Wet Mix Paver Finisher | 2300000 |

| 300 Tons/Hour Capacity Portable Wet Mix Paver Finisher | 2350000 |

| Wet Mix Paver Finisher | 2301000 |

| Wet Mix Paver Machine For Road Construction | 2500000 |

This Data was Last Updated on 2024-12-15

Wet Mix Paver Finisher Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Himalaya Engineering Co. Mehsana, India | 19 Years |

Kaushik Engineering Works Ahmedabad, India | 17 Years |

Kesar Road Equipments ( India ) Pvt. Ltd. Mehsana, India | 13 Years |

Unipave Engineering Products Ahmedabad, India | 11 Years |

Aadesh Industries Mehsana, India | 7 Years |

Quality Engineers Ahmedabad, India | 6 Years |

S K Engineering New Delhi, India | 6 Years |

Speedcrafts Private Limited Patna, India | 4 Years |

Rudra Engineers Ahmedabad, India | 4 Years |

Jay Khodiyar Metal Industries Ahmedabad, India | 3 Years |

Upcoming Tradeshows

Gulfood 2025

Mon, 17 Feb, 2025 - Fri, 21 Feb, 2025

National Expo Raipur 2025

Sun, 19 Jan, 2025 - Wed, 22 Jan, 2025

International Crop Science Conference and Exhibition 2025

Tue, 21 Jan, 2025 - Wed, 22 Jan, 2025

LogiMAT India 2025

Thu, 13 Feb, 2025 - Sat, 15 Feb, 2025

WATER EXPO VIJAYAWADA 2025

Wed, 29 Jan, 2025 - Fri, 31 Jan, 2025

Printing South China 2025

Tue, 04 Mar, 2025 - Thu, 06 Mar, 2025

CHINA INTERNATIONAL FURNITURE FAIR 2025

Tue, 18 Mar, 2025 - Fri, 21 Mar, 2025

INDIA ART FESTIVAL 2024

Thu, 19 Dec, 2024 - Sun, 22 Dec, 2024

MachAuto 2025

Fri, 23 May, 2025 - Mon, 26 May, 2025

10th IMTOS-India Machine Tools Show 2025

Thu, 15 May, 2025 - Sun, 18 May, 2025

Popular Categories