- Tradeindia

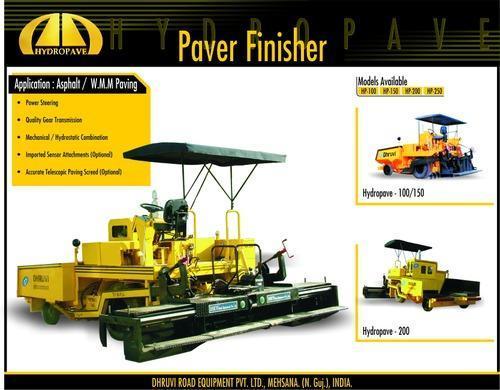

- Road Construction Machinery

- Sensor Paver Finisher

Sensor Paver Finisher

(48 products)Automatic Sensor Paver Finisher

Price: 4800000 INR/Set

MOQ1 Set/Sets

ColorYellow

MaterialSteel

Capacity120 to 150 tons/hour Ton/day

ComputerizedYes

Automatic GradeAutomatic

SizeWidth 2.5 meter to 4.5 meters

Kesar Road Equipments ( India ) Pvt. Ltd.

Mehsana

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller14 Years

Asphalt Paver Finisher (Mechanical And Sensor) - Automatic Grade: Semi-Automatic

Price: 2400000.0 INR/Unit

MOQ1 Unit/Units

ColorYellow

MaterialStainless Steel

ComputerizedNo

Automatic GradeSemi-Automatic

Cooling SystemFrequency Speed Control

WarrantyYes

Lal's Exporters (india) Private Limited

Patna

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller2 Years

Sensor Paver Machine - Color: Yellow

Price: 2000000 INR/Unit

MOQ10 Unit/Units

ColorYellow

Product TypeSensor Paver Machine

General UseIndustrial

MaterialSteel

ComputerizedNo

AutomaticYes

Shivam Construction Company And Earth Movers

Rohtak

Trusted Seller

Trusted Seller Super Seller

Super Seller3 Years

Semi-Automatic Sensor Concrete Paver Machine

Price: 800000 INR/Unit

MOQ1 Unit/Units

MaterialStainless Steel

ComputerizedNo

Automatic GradeSemi-Automatic

Cooling SystemFrequency Speed Control

Asphalt Sensor Paver Machine - Automatic Grade: Semi-Automatic

Price: 2150000.00 INR/Unit

MOQ1 Piece/Pieces

ColorYellow, Black Paint Coated

TypePavers

MaterialMS

Capacity10 Ton

ComputerizedYes

Automatic GradeSemi-Automatic

Aimax Equipment Private Limited

Ahmedabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller2 Years

Yellow And Black Sensor Paver Finisher For Road Construction Industry

Price: 5500000.00 INR/Unit

MOQ1 Unit/Units

ColorYellow and Black

TypePavers

Weight14000.00 Kilograms (kg)

Jay Khodiyar Metal Industries

Ahmedabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller4 Years

View More

Asphalt Sensor Paver Finisher Machine - Color: Yellow And Black

Price : 5500000 INR

Asphalt Sensor Paver Finisher

Price Trend : 4400000.00 - 4800000.00 INR

Black And Yellow Electronic Sensor Dual Purpose Paver Finisher

Price : 5500000.00 INR

Sensor Paver Finisher - Heavy Duty Steel, Customizable Dimensions, Yellow Color | Automatic Hydraulic Control, Adjustable Lifting Height, Sensor Operated

Price Trend : 4400000.00 - 4800000.00 INR

Hydrostatic Sensor Paver Finisher Machine - Metal, Automatic | 200 Capacity, High Operational Reliability, Precision Hydraulic Components

Price Trend : 1800000.00 - 4500000.00 INR

Automatic Esp-05 Sensor Paver Finisher

MOQ1 Unit/Units

MaterialMS

Capacity300 TPH T/hr

ComputerizedNo

Automatic GradeAutomatic

Cooling SystemHuman Machine Interface

ColorYellow

Unipave Engineering Products

Ahmedabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller12 Years

View More

Sensor Paver Finisher - Mild Steel, Standard Size | Automatic Operation, 400 Capacity, Yellow Color, Dual Warranty

Get Best Deal

Automatic Road Sensor Paver Finisher Machine

Get Best Deal

Automatic Crawler Mounted Sensor Paver Finisher

Price : 2000000.00 INR

Automatic Sensor Paver Finisher Capacity: 300 T/Hr

Get Best Deal

Automatic 4.5 Meter Sensor Paver Finishers

Get Best Deal

Semi-Automatic Wheel Mounted Sensor Paver Finisher

Price : 1000000.00 INR

Road Paver Finisher - Automatic Grade: Manual

Price: 2200000 INR/Unit

MOQ1 Unit/Units

ColorYellow

MaterialMild steel

ComputerizedNo

Automatic GradeManual

Dimension (L*W*H)2.5-4.5 W Meter (m)

WarrantyYes

Accel Infratech India Private Limited

Kolkata

Trusted Seller

Trusted Seller Premium Seller

Premium Seller2 Years

Semi Sensor Paver Finisher In Delhi Sk Engineering, Usage/Application: Road Construction Work

Product DescriptionSemi Sensor Paver Finisher In Delhi Sk Engineering

Asphalt Hot Mix Paver Finisher Capacity: 150 To 200 T/Hr

Price: 1950000 INR/Unit

MOQ1 Unit/Units

ColorGreen and Black

TypeAsphalt Mixers

MaterialStainless Steel

Capacity150 to 200 T/hr

Weight1000 Kilograms (kg)

View More

Automatic Hydrostatic Sensor Paver Finisher

Price Trend : 195000.00 - 210000.00 INR

Sensor Paver Finisher Capacity: 300 T/Hr

Price : 1950000 INR

Hydrostatic Sensor Paver Finisher Capacity: 300 T/Hr

Price : 1950000 INR

Sensor Paver Finisher - Mild Steel, 5680 x 3230 x 2930 mm, Yellow | Semi-Automatic, Human Machine Interface, 8500 kg Weight

Price Trend: 250000-3000000 INR/Unit

MOQ1 , Unit/Units

TypePavers

MaterialM.S.

ComputerizedYes

Automatic GradeSemi-Automatic

Cooling SystemHuman Machine Interface

ColorYELLOW

View More

Road Paver Finisher Drop Earrings

Get Best Deal

Automatic Asphalt Sensor Paver Finisher

Price: 4800000 INR/Unit

MOQ1 Unit/Units

ColorYellow

TypePavers

MaterialMS

Automatic GradeAutomatic

View More

Automatic Hydrostatic Sensor Paver Finisher

Price : 4800000 INR

Top Rated Products

Asphalt Paver Finisher (Mechanical And Sensor) - Automatic Grade: Semi-Automatic

Lal's Exporters (india) Private Limited

FAQs Related to Sensor Paver Finisher

Here are some of the primary benefits of using a fully automatic paver:

-Sensor paver finishers measure the thickness of the material being laid, which guarantees that the pavement thickness remains uniform throughout the project, minimising variances and eliminating over- or under-paving.

Paver Finisher Construction By Pandit Enterprise

Price: 90000 INR/Unit

MOQAny Order , Unit/Units

Product TypePaver Finisher

General UseConstruction

Warranty1 Year

Semi Sensor Paver Finisher - Automatic Grade: Manual

Price: 2350000 INR/Milliampere

MOQ1 Unit/Units

ColorYellow

TypePavers

MaterialMetal

ComputerizedNo

Automatic GradeManual

SizeStandard

View More

Semi-Automatic Semi Sensor Mechanical Paver Finisher

Price : 19 lakh INR

Metal Hydrostatic Sensor Paver Finisher

Price : 3900000 INR

Sensor Paver Finisher - Metal, 6.61m Length x 3.14m Width x 3.43m Height | Hydraulic, Diesel Power, 300 TPH Laying Capacity, Automatic Grade Control

Price : 3900000 INR

Waken Yellow Hydrostatic Sensor Paver Finisher

Price : 40 Lakh INR

Sensor Paver

MaterialSteel

DimensionsVariable

PowerHydraulic

Paving width3-16m

Paving capacity180sqm/hr

FeaturesHigh precision, Durable design, Easy operation, Time saving, Cost effective, Reliable performance, High efficiency

View More

Sensor Paver Finisher

Get Best Deal

Asphalt Sensor Paver Finisher

Dimensions10M X 4M X 3M

Weight20000 Kg

Engine300 Hp

MaterialSteel

Wheels8

SensorsMultiple

View More

Hydrostatic Sensor Paver Finisher -SIL-550-HS

Get Best Deal

Hydrostatic Sensor Paver Finisher

Get Best Deal

Hydrostatic Sensor Paver Finisher -SIL-550-HS

Get Best Deal

Sensor Paver Finisher - High Grade Material, Durable Design | Exceptional Quality, Nationwide Appreciation

Get Best Deal

Hydrostatic Sensor Paver Finisher -SIL-550-HSW

Get Best Deal

Tracked Hydrostatic Sensor Paver Finisher - Steel, Variable Dimensions, Powerful Engine | Cost Effective, Durable Build, Easy Operation, High Efficiency, Hydrostatic Drive, Precision Paving, Multiple Sensors, Heavy-Duty Tracks

MaterialSteel

DimensionsVariable

EnginePowerful

TracksDurable

SensorsMultiple

WeightHeavy

Sensor Mechanical Paver

Sample AvailableYes

Sample PolicyContact us for information regarding our sample policy

Hydrostatic Sensor Paver Finisher - Customized with Grade and Slope Sensors | High-Quality Performance for Precision Paving

Main ComponentsSmc, Keyence, Omron, Panasonic, Siemens, Nuodajia, Shanghai Jianping

Rotor Diameter25-40Mm

Rotor Weight<0.5Kg

Iron Core Length20-60Mm

Balancing Speed1000-3000Rpm

PowerAc380V

View More

Hydrostatic Sensor Paver Finisher Machine

Get Best Deal

Hydrostatic Sensor Paver Finisher Machinery

Get Best Deal

Semi Sensor Paver Finisher

Get Best Deal

Hydrostatic Sensor Paver Finisher - High Grade Raw Materials | Customizable with Grade and Slope Sensor

Get Best Deal

Hydrostatic Sensor Paver Finisher for Wet Mix

Get Best Deal

Mechanical Wet Mix Paver

Product TypeRoad Paver

Primary ColorRed

MaterialSteel

Power SourceEngine

DimensionsVariable

Weight1000kg

Automatic Aspahlt Paver

Price: 1 USD ($)/Unit

MOQ1 Unit/Units

TypePavers

MaterialAsphalt

Capacity900Ton/Hr Kg/hr

ComputerizedYes

Automatic GradeAutomatic

Cooling SystemPLC Control

Manual Asphalt Sensor Paver Finisher

Price Trend: 20000.00 - 50000.00 INR/Unit

MOQ1 Unit/Units

TypePavers

MaterialMetals and metal alloys

ComputerizedNo

Automatic GradeManual

Size2.5mm

WarrantyYes

View More

Sensor Paver Finisher - Steel, 2.5 m Width x 6.5 m Length x 2.5 m Height, 100 hp Diesel Engine, 5000 kg Weight

Get Best Deal

Semi-Automatic Mechanical Sensor Paver Finisher

Price Trend : 2200000.00 - 2500000.00 INR

Hydro Static Sensor Paver Finisher

Get Best Deal

Sensor Paver Finisher - Advanced Range with Imported Components | Energy Efficient for Highways, Airports, Motorways, and Rural Roads

MaterialSteel

DimensionsVariable

SensorsMultiple

WeightHeavy

CapacityHigh

FeaturesSensor Accuracy, Precise Paving, Energy Efficient, Cost Savings, Durable Design, Easy Operation, High Output

Sensor Paver Finisher - Solid Rubber Coated & Pneumatic Tires, 12mm to 200mm Thickness Laying Capacity, Hydraulically Driven Screed

EngineKiloskar diesel

TiresSolid & pneumatic

ScreedHydraulically driven

Thickness12mm-200mm

Width2.5m-4.0m

MaterialSteel, rubber

Sensor Paver Finisher - Fully Hydrostatic and Infinitely Variable Traction Drive | Top Quality Materials, Advanced Feeder & Auger Drives

EnginePowerful Engine

WeightHeavy Duty

DimensionsLarge Size

MaterialSteel Body

CapacityHigh Capacity

DriveHydrostatic Drive

Industrial Paver Machine Rental Service

Payment TermsOthers

Sample PolicyContact us for information regarding our sample policy

Main Domestic MarketAll India

Hydrostatic Sensor Paver Finisher - Premium Quality Material | High Performance and Reliable Operation

MaterialSteel

DimensionsVariable

EnginePowerful

WeightHeavy-Duty

CapacityLarge

SensorsMultiple

A.K Engineering

New Delhi

Deals in:

Latest from Sensor Paver Finisher

WMM Hydrostatic Sensor Paver Finisher

By:

Unipave Engineering Products

Semi Sensor Paver Finisher In Delhi Sk Engineering

By:

S K Engineering

Tracked Hydrostatic Sensor Paver Finisher

By:

Jay Khodiyar Metal Industries

Hydrostatic Sensor Paver Finisher

By:

Ashtvinayak Industries

Sensor Paver Finisher

By:

Hi Tech India

Hydrostatic Sensor Paver Finisher

By:

Hindustan Road Equipments

Popular Sensor Paver Finisher

What is a sensor paver finisher?

A sensor paver finisher is a piece of heavy machine used in road and paving constructions. It is specially intended to lay asphalt or concrete precisely and uniformly, resulting in a smooth and even surface for roads, highways, airport runways, and other paved surfaces. The integrated sensing and control system is the defining feature of a sensor paver finisher. It is outfitted with different sensors and equipment that measure and monitor the paving process, enabling real-time modifications to reach the appropriate pavement thickness, slope, and smoothness.

In this Sensor paver finisher, there are some sensors. Let’s have a look:

-Grade sensors are those sensors that are used for detecting the existing surface levels and sending them back to the control system. This process helps the machine maintain the required grade and slope.

-To find out the thickness of the deposited material, sonic sensors are widely used.

-To check that the pavement's longitudinal and transverse slopes are accurate, slope sensors are being used.

-Auger sensors track the flow of asphalt or concrete from the hopper to the screed.

-This is critical for attaining exact and uniform paving outcomes, as well as improving the longevity and smoothness of roads and other paved areas.

How does Sensor Paver Finisher work?

A sensor paver finisher ensures correct and homogeneous paving of asphalt or concrete surfaces by integrating modern sensing technologies with precise control systems. Here's a quick rundown of how a sensor paver finisher works:

-Prior to paving, the road or area to be paved is usually prepared by removing any existing pavement, grading the surface, and ensuring good drainage.

-The sensor paver finisher has a hopper that contains the asphalt or concrete mixture. Trucks or conveyor systems are used to load the material into the hopper.

-The material is then carried from the hopper to the machine's back, where it is uniformly distributed throughout the width of the paver by a series of augers and distribution mechanisms.

-The material is compacted by the tamper bar, and the surface is levelled and finished by the screed plate.

-The sensor paver finisher is outfitted with a variety of sensors strategically placed at important spots.

-After this, when the sensor data is transmitted to the paver’s control system, the system analyses it and makes the modifications to the machine’s operations.

-According to the data provided, the control system automatically adjusts the screed’s angle, height, and other settings too.

-To have a smooth and even surface, the screed compacts and levels the material, and then the sensor paver finisher moves forward.

-Once the material has been laid, other additional operations are conducted to increase the density and stability of the pavement.

Features of Sensor Paver Finisher:

Sensor paver finishers include a variety of characteristics that allow for precise and efficient paving operations.

-These sensors collect real-time data on existing surface levels, material thickness, slope, and material flow, enabling precise modifications during the paving process.

-The control system guarantees that the pavement is placed as per the specifications, ensuring consistency and precision.

-It continuously monitors and optimises the paving process. This feature reduces human mistakes while maintaining uniform quality.

-Tamper bars, vibratory devices, and heating components may be included in the screed design to aid in compaction, smoothing, and surface finishing.

-For accurate paving, the material handling system maintains a proper flow of material.

-Sensor paver finishers are self-propelled and steerable, allowing them to travel smoothly along the paving course.

-These finishers include an operator interface that allows the operator to monitor and adjust the machine's activities.

-Apart from this, the sensor paver finisher may come with optional attachments or features, depending on the model and application.

Applications of Sensor Paver Finisher:

Sensor paver finishers are versatile machines that can be used in a variety of road-building and paving jobs. These are commonly used in the following applications:

-Sensor paver finishers are commonly used in the construction of new roads and highways.

-They can correctly pave extra lanes or widen the current road surface, ensuring perfect connection with the pre-existing pavement.

-Pavers are critical in the building and maintenance of airport runways.

-These finishers are widely employed in the construction of parking lots, both commercial and residential.

-They are utilised in industrial settings to build or repair roads and driveways, providing durable and dependable surfaces for heavy gear and vehicles.

-These finishers are used in the construction of recreational areas like sports fields, jogging tracks, and cycling routes.

-They are utilised in residential construction projects to pave roads, sidewalks, and pathways within housing developments.

-They are also used in the restoration and maintenance of existing roads and pavements.

-Sensor paver finishers are critical in delivering precise and high-quality paving results in a variety of applications.

Advantages of Sensor Paver Finisher:

Sensor paver finishers with their advanced sensing technology and accurate control systems provide various advantages over traditional paving processes. Here are some of the primary benefits of employing sensor paver finishers:

-These finishers ensure a high level of paving quality, in comparison to manual or conventional procedures.

-This finisher’s inclusion of sensors and control systems, improves accuracy and precision throughout the paving process.

-During road construction operations, they help in reducing the time and money required to a great extent.

-This paving machine makes the paving process more efficient and productive.

-This finisher ensures that the paved surface is consistent and uniform too.

-Using this machine helps in reducing the environmental impact of paving operations.

-These finishers are built with the operator in mind.

Overall, their modern technology and automation help to accelerate project completion, reduce environmental impact, and improve operator comfort and safety. Because of these benefits, sensor paver finishes are a popular choice for road building and paving operations.

Client Testimonials & Reviews

RaviParekh

UNIVERSAL ENGINEERS

We would like to introduce our company as "Universal Engineers" manufacturer and exporters of Road Construction Machinery. Since last 3 years we had under taken services of "Tradeindia.com" and start getting immediate responses from prospective customers from India and Abroad. Your creative catalog hosting and allied services like call me free, sms and trust Stamp, banner, language converter for 10 different countries are proving exclusive to us and creates an elite image of our company as tech-savvy and customer friendly company. Moreover, keywords for inquiries of our products are prompting our buyers to directly attract to our catalogue / website and thus, creates an direct / indirect pull in to Internet World Market with respect to our products. We look forward to reap more benefits in coming time to enable us share you some more with association with TradeIndia.com.

Sensor Paver Finisher Price List

Product Name | Expected Price |

|---|---|

| Semi Sensor Paver Finisher | 2350000 |

| Road Paver Finisher | 2200000 |

| Asphalt Sensor Paver Machine | 2150000 |

| Asphalt Paver Finisher (Mechanical and Sensor) | 2400000 |

| Sensor Concrete Paver Machine | 800000 |

| Asphalt Sensor Paver Finisher | 4800000 |

| Hydrostatic Sensor Paver Finisher | 4800000 |

| Sensor Paver Finisher | 3900000 |

| Asphalt Hot Mix Paver Finisher | 1950000 |

| Apollo paver finisher | 1950000 |

This Data was Last Updated on 2025-09-01

Sensor Paver Finisher Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Kesar Road Equipments ( India ) Pvt. Ltd. Mehsana, India | 14 Years |

Unipave Engineering Products Ahmedabad, India | 12 Years |

S K Engineering New Delhi, India | 7 Years |

A.k Engineering New Delhi, India | 5 Years |

Sana Diamond Engi-mech Llp Ahmedabad, India | 4 Years |

Jay Khodiyar Metal Industries Ahmedabad, India | 4 Years |

Shivam Construction Company And Earth Movers Rohtak, India | 3 Years |

Lal's Exporters (india) Private Limited Patna, India | 2 Years |

Aimax Equipment Private Limited Ahmedabad, India | 2 Years |

Accel Infratech India Private Limited Kolkata, India | 2 Years |

Upcoming Tradeshows

ENGIMACH 2025

Wed, 03 Dec, 2025 - Sun, 07 Dec, 2025

China (Guzhen) International Lighting Fair 2025

Wed, 22 Oct, 2025 - Sat, 25 Oct, 2025

India Med Expo Hyderabad 2025

Fri, 05 Dec, 2025 - Sun, 07 Dec, 2025

YARNEX - Mumbai 2025

Thu, 27 Nov, 2025 - Sat, 29 Nov, 2025

Spectra Expo 2026

Thu, 05 Feb, 2026 - Sat, 07 Feb, 2026

INDIA GREEN ENERGY EXPO 2026

Wed, 29 Jul, 2026 - Fri, 31 Jul, 2026

Dairy Expo 2025

Thu, 11 Dec, 2025 - Sat, 13 Dec, 2025

Dahej Industrial Expo 2025

Wed, 12 Nov, 2025 - Fri, 14 Nov, 2025

Paper India Expo 2026

Mon, 13 Apr, 2026 - Wed, 15 Apr, 2026

WOOD ASIA 2026

Fri, 16 Jan, 2026 - Mon, 19 Jan, 2026

Popular Categories