- Tradeindia

- Road Construction Machinery

- Asphalt Paver

Asphalt Paver

(154 products)Asphalt Paver Finisher - Automatic Grade: Automatic

Price: 2450000 INR/Piece

MOQ1 Piece/Pieces

ColorOrange

General UseIndustrial

MaterialSteel

Automatic GradeAutomatic

ComputerizedNo

AutomaticYes

Lal's Exporters (india) Private Limited

Patna

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller2 Years

Orange Automatic Road Paver Finisher With 1 Year Warranty

Price: 2450000 INR/Piece

MOQ1 , Piece/Pieces

ColorOrange

TypePavers

Automatic GradeAutomatic

SizeStandard

Warranty1 Year

Speedcrafts Private Limited

Patna

Trusted Seller

Trusted Seller Super Seller

Super Seller5 Years

Aggregate Bitumen Chip Spreader Machine - Automatic Grade: Automatic

Price: 3650000.00 INR/Piece

MOQ1 Piece/Pieces

Colorwhite, Yellow

TypePavers

MaterialMild Steel

Capacity10 m3/hr

ComputerizedYes

Automatic GradeAutomatic

Aimax Equipment Private Limited

Ahmedabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller2 Years

Yellow And Black Super Asphalt Paver For Road Construction Work

Price: 5500000.00 INR/Unit

MOQ1 Unit/Units

ColorYellow and Black

TypePavers

Weight14000.00 Kilograms (kg)

View More

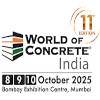

Mechanical Paver - Heavy-Duty Steel Frame, Versatile Usage in Asphalt and Concrete Paving

Price Trend : 4400000.00 - 4800000.00 INR

Automatic Mechanical Asphalt Paver Finisher Machine

Price Trend : 1800000.00 - 2200000.00 INR

Asphalt Road Paver

Price Trend : 4500000.00 - 6000000.00 INR

Asphalt Paver With Parabolic Screed

Price Trend : 4500000.00 - 5500000.00 INR

Mechanical Asphalt Paver Machine

Price Trend : 4500000.00 - 5500000.00 INR

Asphalt Hydrostatic Paver Finisher

Price Trend : 4500000.00 - 6000000.00 INR

Asphalt Paver Finisher - Durable High-Grade Steel, Versatile Size for Efficient Surface Application

Price Trend: 2000000.00 - 5000000.00 INR/Unit

MOQ1 Unit/Units

Supply Ability1 Per Month

Delivery Time1 Minutes

Main Domestic MarketAll India

Unipave Engineering Products

Ahmedabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller12 Years

View More

Semi-Automatic Asphalt Sensor Paver Finisher Machine

Get Best Deal

Automatic 5.5 Meter Asphalt Paver Finisher

Get Best Deal

Road Paver Finisher - Automatic Grade: Manual

Price: 2200000 INR/Unit

MOQ1 Unit/Units

ColorYellow

MaterialMild steel

ComputerizedNo

Automatic GradeManual

Dimension (L*W*H)2.5-4.5 W Meter (m)

WarrantyYes

Accel Infratech India Private Limited

Kolkata

Trusted Seller

Trusted Seller Premium Seller

Premium Seller2 Years

Asphalt Plant - Automatic Grade: Automatic

Price: 3400000 INR/Plant

MOQ1 Plant/Plants

ColorMulticolor

TypeAsphalt Plant

MaterialMild Steel

ComputerizedNo

Automatic GradeAutomatic

Drive TypeElectric

Semi-Automatic Road Asphalt Paver Capacity: 10/15 To 60/90 T/Hr

Price: 1750000 INR/Set

MOQ1 Set/Sets

MaterialMS

Capacity10/15 to 60/90 T/hr

Asphalt Road Paver Finisher Size: 4.5 Mtr

Price: 1850000 INR/Piece

MOQ01 Piece/Pieces

TypePavers

Size4.5 mtr

Weight10000 Kilograms (kg)

Warranty1 year

Sarvatman Road Equipments Private Limited

Visnagar

Trusted Seller

Trusted Seller7 Years

Durable Screed Heating Rod

Product DescriptionOur organization hold expertise in manufacturing and supplying superior grade Durable Screed Heating Rod in Ahmedabad, Gujarat, India. Our offered Screed Heating Rod is widely appreciated by our customers, which are situated all round the nation. Known for its best quality, clients can avail this Sc

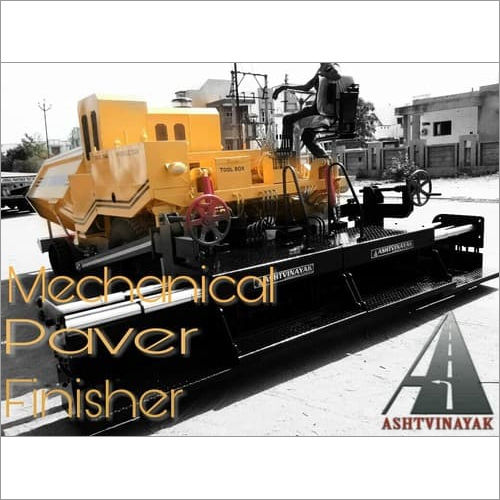

Semi-Automatic Asphalt Paving Machine

Price: 1950000 INR/Unit

MOQ1 Unit/Units

ColorYellow and Black

TypePavers

MaterialStainless Steel

Capacity300 T/hr

Automatic GradeSemi-Automatic

Weight1000 Kilograms (kg)

View More

Ashtvinayak Asphalt Paver Machines Capacity: 300 T/Hr

Price : 1950000 INR

Asphalt Hot Mix Paver Finisher Capacity: 150 To 200 T/Hr

Price : 1950000 INR

Asphalt Paver Machine Capacity: 150-200 T/Hr

Price : 1950000 INR

Mechanical Asphalt Road Paver Machine - Stainless Steel, 1000 Kilograms, Yellow and Black | 300 T/hr Capacity, High-Performance Design

Price : 1950000 INR

Automatic Asphalt Road Paver Finisher

Price : 1900000 INR

Semi-Automatic Asphalt Paver

Price: 2400000 INR/Unit

MOQ1 Kilograms/Kilograms

Colorparty required

TypePavers

Materialmechanical asphalt paver finisher

Capacity100 Ton/day

ComputerizedNo

Automatic GradeSemi-Automatic

Top Rated Products

Asphalt Paver Finisher - Durable High-Grade Steel, Versatile Size for Efficient Surface Application

Unipave Engineering Products

FAQs Related to Asphalt Paver

The most common asphalt pavement problems are mentioned below:

Alligator Cracking: It is a series of hairline breaks that intersect with one another in a frame-like formation. The best solution to this problem is to remove the damaged, localized part of the asphalt.

Longitudinal Cracking: The cracks are long fractures that go through the entire pavement length. This problem can be resolved by overhauling or repairing the whole surface.

Transverse Cracking: Transverse cracks are longitudinal crack formations that can be caused by low-quality construction as well as reflective cracks.

Edge Cracking: This cracking grows at the pavement corners or near the sides of the pavement. It can also affect the middle of the structure and result in a weak foundation or a lack of proper support. This crack can be filled or sealed with a hot or cold patch so that future cracking can be prevented.

Block Cracking: This crack is developed in large square or rectangular outlines and is known as block cracking.

Joint Reflection Cracking: It occurs because of thermal as well as moisture fluctuations in the asphalt pavement’s subbase and can result in the expansion of surface cracking. This problem can be solved by hiring professional asphalt crack repair services.

Slippage Cracking: Slippage cracks occur because of a lack of cohesion and improper compaction between the asphalt pavement layers. This problem can be dealt with by removing the asphalt in the affected area completely or partially.

Potholes: Potholes are one of the challenges faced by asphalt pavers, which can expand after they come into contact with various environmental factors.

In addition to these, there can also be problems that operators can face while operating asphalt pavers, such as uneven pavement, screed malfunction, insufficient compaction and material jamming.

Asphalt is bitumen of different grades that are used for the purpose of paving and levelling. They are the most versatile, hard-wearing, and resilient paving materials, with low maintenance and high cost-effectiveness. A variety of mixtures are used in the process, including:

- Asphalt Cement

- Cutback Asphalt

- Natural Asphalt

- Mastic Asphalt

- Residual Asphalt

- Asphalt Emulsion

Paver Finisher - 182Kw Power, 9921 lb Operating Weight, 5750x2950x2500 mm Dimensions | Adjustable Speed, Durable Design, Smooth Finish, Versatile Sizes

Model NumberPF

Power182kw

Operating Weight9921 lb

Max Paving Thickness300

Weight100000

Standard Paving Width1400-2600 mm

Asphalt Melano Paver Blocks - Cement, Concrete, Sand, 60mm Thickness | Multicolour, Interlocking Design, Solid Porosity, Rough Surface

Price: 14 INR/Unit

MOQ6000 Unit/Units

TypeInterlock Block

MethodAerated Autoclaved

ColorMulticolour

PorositySolid

Thickness60 Millimeter (mm)

MaterialCement, Sand, Concrete

Asphalt Pavers - Automatic Grade: Automatic

Price: 2250000 INR/Unit

MOQ1 Unit/Units

ColorYellow

TypeAsphalt Mixers

MaterialMetal

ComputerizedNo

Automatic GradeSemi-Automatic

SizeStandard

View More

Ashphalt Paver Finisher WAP 450 (HES)

Get Best Deal

200 Ton Asphalt Paver Finisher - Automatic Grade: Automatic

Price : 2800000 INR

Waken Asphalt Paver Finisher - Automatic Grade: Automatic

Price : 2250000 INR

Automation Multitech Asphalt Paver Finisher For Road Construction Work

Price : 2250000 INR

Asphalt Paver Finisher

Get Best Deal

Asphalt Mechanical Paver - 5680 mm Length, 2900 mm Width, 2680 mm Height | KIRLOSKAR 60 HP Engine, Paving Width 2.5 to 4 Mtrs, Paving Speed 9.4 to 28.2 Mtrs/Min, 10 to 200 mm Paving Thickness, Solid Rubber Front Tyres

Length5680 Mm

Width2900 Mm

Height2680 Mm

EngineKirloskar 4R-1040-44.2Kw

Hopper Capacity5 Cubic Meters

Paving Width2.5 To 4 Mtrs

View More

Industrial Asphalt Paver Machine

Get Best Deal

Asphalt Semi Hydro Paver

Get Best Deal

Solid Asphalt Paver Finisher

Get Best Deal

High Performance Asphalt Paver Machine - Premium Quality Components, Versatile Designs & Sizes, Smooth Operation

Get Best Deal

Asphalt Mechanical Paver Finisher

Get Best Deal

Asphalt Paver - Durable Engineered Design | Excellent Mobility, Superb Visibility, Comfortable Operations, Reliable Performance

EnginePowerful

MaterialSteel

DimensionsVariable

WeightHeavy

TracksRubber

CapacityHigh

Paver Finisher - Premium Quality Material, Advanced Technology | Ideal for Road, Highway, and Airport Paving Projects

Engine Power150 Hp

Paving WidthVariable

MaterialSteel

Weight10000 Kg

DimensionsLength 8M

Height3M

Asphalt Paver - Steel Construction, 7.5m L x 2.5m W x 3.0m H, 130 hp Engine Power | 12,000 kg Operating Weight, 200 L Fuel Tank Capacity, 2.5m Paving Width, 100mm Paving Thickness

EnginePowerful Diesel

MaterialHigh-Strength Steel

DimensionsLarge, Variable

WeightHeavy-Duty

CapacityHigh Asphalt

ScreedAdjustable Width

Automatic Pave Saw APS

MaterialsQuality Grade

Control UnitElectronic

DisplayTouch Screen

Operating SystemWindows Based

Cutting SpeedAdjustable

Specimen TypesVarious

Paver Finisher - Quality-Approved Material, Versatile Specifications for Diverse Applications

Weight10 Tons

Dimensions10X5X3 M

EngineDiesel

MaterialSteel

Capacity10 M3

Speed10 Kmph

Writgen Slip Form Paver Rental Service

Price: 1500000 INR/Unit

MOQ1 Unit/Units

Delivery Time3 Days

Barbagreen S131 Asphalt Paver - USED 1995 Model, 4.00 MT Paving Screed | Rugged Structure, Excellent Performance, Long Service Life

MakeBarbagreen

ModelS131

Year1995

Screed4.00M

Tyres60%

ConditionVery Good

View More

Used Asphalt Paver

Get Best Deal

Blaw Knox Bk75 Asphalt Paver

Get Best Deal

Marini P230 Asphalt Pavers

Get Best Deal

Asphalt Paver Dynapac 11011R

Get Best Deal

Barbagreen S131 Asphalt Paver - Steel, 3.80 MT Dimensions | Used with 70% Good Condition Tyres, 7,000 Working Hours

Get Best Deal

Asphalt Paver Bitelli BB50

Get Best Deal

Automatic Aspahlt Paver

Price: 1 USD ($)/Unit

MOQ1 Unit/Units

TypePavers

MaterialAsphalt

Capacity900Ton/Hr Kg/hr

ComputerizedYes

Automatic GradeAutomatic

Cooling SystemPLC Control

Asphalt Paver Machine - Steel, 7000X2500X3000Mm, 150T/H, 132Kw Engine | Durable Design, Easy Maintenance, High Efficiency, Precise Paving, Smooth Operation

EngineDeutz

Power132Kw

Weight18000Kg

Dimensions7000X2500X3000Mm

Screed Width2500Mm

MaterialSteel

View More

Manual Asphalt Sensor Paver Finisher

Price Trend : 20000.00 - 50000.00 INR

Automatic Heavy Duty Asphalt Paver Machine

TypeRoad Marking Machines

Automatic GradeAutomatic

ColorYellow

Asphalt Paver Drag Chain

Product DescriptionCondition : New Pattern : Plain Surface Treatment : Polished Corrosion Resistance : Yes Application : Automobile, Sugar Cane, Cement Industry Waste Water And Forest Industry

Asphalt Paver - Metal Material, Standard Size, Yellow Color | High Strength, Heavy-Duty, Easy to Operate

Price: 5000000 INR/Piece

MOQ1 Piece/Pieces

ColorYellow

Capacity406 tons/h T/hr

Product TypeAsphalt pavers

Test Range1.75 m - 3.42 m

Usageroadwork

MaterialMetal

Latest from Asphalt Paver

Mechanical Asphalt Paver Finisher

By:

Unipave Engineering Products

Asphalt Paver Finisher

By:

Himakshi Road Cons. Equipments Pvt. Ltd.

Asphalt Paver Finisher Machine In Delhi Sk Engineering

By:

S K Engineering

Introduction to Asphalt Pavers

Asphalt pavers are indispensable construction machines that are mainly utilised for laying asphalt. The mix of asphalt is loaded into the machine, which then lays and spreads out the asphalt for the further process of levelling and compaction. These construction machines are utilised to lay the asphalt in a convenient, safe, smooth, and consistent way. Also, these pavers allow for fast construction.

How do asphalt pavers work?

The main task of asphalt pavers is to dispense and compact the asphalt layers onto different surfaces so that roads, walkways, parking lots, and other areas can be paved. Most of these machines are self-driven through tracks or towed by a dump truck. The pavers are assembled with two major components: the screed and the tractor. The tractor is used to tow the screed, through which the shaping and levelling of the asphalt take place.

The pavers function with the help of a dump truck, which fills the paver’s hopper with asphalt. As the users begin to operate the gear and make a forward move, the feeder conveyors convey the material to the backside of the paver. The users can adjust the augers’ width so as to match all application needs. As the asphalt is pushed out, the screed afterward levels and compacts all layers of material. The asphalt screeds are incorporated with heated screed plates, which assist in adjusting the width hydraulically. The operation mechanism of the asphalt pavers requires less handwork.

Different Types of Asphalt Pavers

Apollo Paver Finishers

The construction equipment is helpful in laying Portland cement concrete and asphalt concrete on roads, parking lots, bridges, and other such places.

Wheeled Pavers For Large-scale Projects

The pavers are used to place both binding courses as well as surface lifts. The machine models are available with a standard paving thickness of 2.55 metres to 4.9 metres. The size and capacity of the models make them the ideal fit for larger road projects. It also has a specialised levelling system that can be attached to the control unit.

Tracked Asphalt Pavers

These particular pavers are utilised for paving assorted materials from base courses on varied terrains. They are applicable to both large and medium-scale projects. The latest models of these types have a smart power-saving mode.

Mini Asphalt Pavers For Small-sized Projects

The pavers are of modern technology and assist in repair work as well as in the smooth construction of sports grounds, cycle paths, parking lots, and footpaths. These pavers are used to fill trenches. Also, they can pave surfaces in underground parking decks and halls, completing many landscaping projects. Its repositioning function adds to its user-friendliness.

Key Components of Asphalt Pavers

Modern asphalt pavers are composed of different components, and the major ones are the engine, drive tracks, hopper, hydraulic drives, and controls, distribution augers, feeding conveyors, and screed. The screed of the pavers is included with levelling arms, end plates, burners, moldboard, slope sensors, and vibrators.

Benefits of Using Asphalt Pavers

Asphalt pavers offer several benefits, including cost efficiency, a reduction in noise pollution, and comfort. These are apt for road construction and maintenance, which add to the benefits for all road users and the environment.

The paver equipment has the capacity to cover up the potholes by resting a strong asphalt layer on them. Once the material—cement, concrete, clay, or any other material—is jam-packed in the equipment, it provides a flat, even, and smooth layer of asphalt. Other benefits are speed, precision, versatility, low material cost, safety, affordability, custom design flexibility, high strength, weather resistance, etc.

Client Testimonials & Reviews

RaviParekh

UNIVERSAL ENGINEERS

We would like to introduce our company as "Universal Engineers" manufacturer and exporters of Road Construction Machinery. Since last 3 years we had under taken services of "Tradeindia.com" and start getting immediate responses from prospective customers from India and Abroad. Your creative catalog hosting and allied services like call me free, sms and trust Stamp, banner, language converter for 10 different countries are proving exclusive to us and creates an elite image of our company as tech-savvy and customer friendly company. Moreover, keywords for inquiries of our products are prompting our buyers to directly attract to our catalogue / website and thus, creates an direct / indirect pull in to Internet World Market with respect to our products. We look forward to reap more benefits in coming time to enable us share you some more with association with TradeIndia.com.

Asphalt Paver Price List

Product Name | Expected Price |

|---|---|

| Asphalt Paver Finisher | 2800000 |

| Asphalt Pavers | 2250000 |

| Aggregate Bitumen Chip Spreader Machine | 3650000 |

| Road Paver Finisher | 2200000 |

| Asphalt Paver | 5000000 |

| Asphalt Paver Finisher | 2450000 |

| asphalt paver | 2400000 |

| Hydraulic Paver Machine | 2500000 |

| Semi-Automatic Road Asphalt Paver | 1750000 |

| Asphalt Road Paver Finisher | 1850000 |

This Data was Last Updated on 2025-07-31

Asphalt Paver Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Unipave Engineering Products Ahmedabad, India | 12 Years |

S K Engineering New Delhi, India | 7 Years |

Sarvatman Road Equipments Private Limited Visnagar, India | 7 Years |

Speedcrafts Private Limited Patna, India | 5 Years |

Jay Khodiyar Metal Industries Ahmedabad, India | 4 Years |

Hindustan Industries New Delhi, India | 4 Years |

Lal's Exporters (india) Private Limited Patna, India | 2 Years |

Aimax Equipment Private Limited Ahmedabad, India | 2 Years |

Accel Infratech India Private Limited Kolkata, India | 2 Years |

Upcoming Tradeshows

Autoserve 2025

Thu, 09 Oct, 2025 - Sat, 11 Oct, 2025

China (Guzhen) International Lighting Fair 2025

Wed, 22 Oct, 2025 - Sat, 25 Oct, 2025

Delhi Water Expo 2025

Thu, 21 Aug, 2025 - Sat, 23 Aug, 2025

INDUS-Tech Expo 2025

Fri, 19 Dec, 2025 - Mon, 22 Dec, 2025

Aesthetic Masterclass 2025

Thu, 28 Aug, 2025 - Fri, 29 Aug, 2025

Aquatech China 2025

Wed, 05 Nov, 2025 - Fri, 07 Nov, 2025

World Food India 2025

Thu, 25 Sep, 2025 - Sun, 28 Sep, 2025

WORLD OF CONCRETE INDIA 2025

Wed, 08 Oct, 2025 - Fri, 10 Oct, 2025

Water Expo Kochi 2025

Thu, 18 Sep, 2025 - Sat, 20 Sep, 2025

INTEXT Expo 2026

Fri, 16 Jan, 2026 - Mon, 19 Jan, 2026

Popular Categories