- Tradeindia

- Road Construction Machinery

- Wet Mix Paver

Wet Mix Paver

(52 products)Semi-Automatic Wet Mix Paver Finisher

Price: 2200000 INR/Set

MOQ1 Set/Sets

ColorYellow

TypePavers

Capacity150 to 200 tons/hour Ton/day

ComputerizedNo

Automatic GradeSemi-Automatic

Power105 Horsepower (HP)

Kesar Road Equipments ( India ) Pvt. Ltd.

Mehsana

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller14 Years

View More

Semi-Automatic Wm-6 Wet Mix Paver

Price : 2500000 INR

Semi-Automatic Wet Mix Macadam Paver Finisher

Price : 25000000 INR

Semi-Automatic Apollo Wet Mixing Paver

Price : 2200000 INR

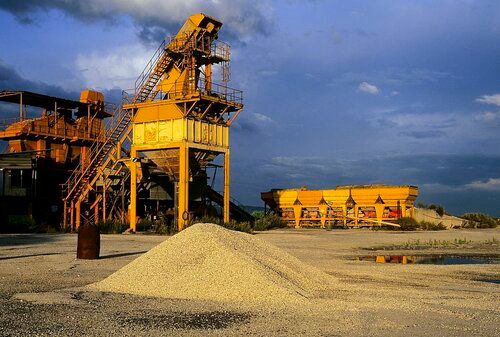

Wet Mix Macadam Plant - Automatic Grade: Semi-Automatic

Price: 2000000 INR/Piece

MOQ1 Piece/Pieces

ColorYellow

General UseIndustrial

MaterialStainless Steel

Automatic GradeSemi-Automatic

Cooling SystemPLC Control

ComputerizedNo

Lal's Exporters (india) Private Limited

Patna

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller2 Years

Wet Mix Paver - Steel, 2.5 to 4.5 Mtrs Width | High-Efficiency Mixing, User-Friendly Design, Precision Controls

Price: 2500000 INR/Unit

MOQ1 Unit/Units

Product TypeWet Mix Paver

General UseRoad Construction

MaterialSteel

Weight (kg)10 Tonne

AutomaticYes

Voltage110-240 Volt (v)

Jay Khodiyar Metal Industries

Ahmedabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller4 Years

View More

Wet Mix Mechanical Paver Finisher

Price Trend : 4500000.00 - 6000000.00 INR

Metal Wet Mix Paver Finisher Machine

Price Trend : 2000000.00 - 2500000.00 INR

Automatic Wet Mix Asphalt Paver Machine

Price Trend : 1800000.00 - 4500000.00 INR

Automatic Sensor Paver

Price: 2000000.00 INR/Unit

MOQ1 Unit/Units

ColorYellow

MaterialMS

ComputerizedNo

Automatic GradeAutomatic

Cooling SystemHuman Machine Interface

Warranty1 Year

Unipave Engineering Products

Ahmedabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller12 Years

View More

Automatic Mechanical Wet Mix Paver

Price : 2000000.00 INR

Automatic Wet Mix Sensor Paver Finisher

Get Best Deal

Yellow Wet Mix Paver

Product Typewet mix paver machine

General UseConstruction of Road

MaterialOther

Weight (kg)90000 Kilograms (kg)

ComputerizedNo

AutomaticNo

Asphalt Cum Wet Mix Paver Finisher - Stainless Steel, 900 kg Weight, Yellow and Black Color | Semi-Automatic, 150-200 T/hr Capacity, Air Break System

Price: 1950000 INR/Unit

MOQ1 Unit/Units

ColorYellow and Black

TypeAsphalt Mixers

MaterialStainless Steel

Capacity150 to 200 T/hr

Automatic GradeSemi-Automatic

Weight900 Kilograms (kg)

Semi Hydro Wet Mix Paver

EnginePowerful Engine

DimensionsCompact Size

WeightHeavy-Duty

MaterialSteel Construction

CapacityHigh Output

SpeedVariable Speed

View More

Asphalt Cum Wet Mix Paver Finisher - Mild Steel, 5560x3100x3000 mm, Yellow and Black | Semi-Automatic, Computerized, User-Friendly Design, Rustproof Surface

Price : 250000-3000000 INR

Semi-Automatic Wet Mix Asphalt Paver Finisher

Price : 250000.00-3000000.00 INR

Automatic Wet Mix Paver Finisher

Price : 250000-3000000 INR

Wet Mix Paver Finisher Machine

Get Best Deal

Semi Hydro Wet Mix Paver

Get Best Deal

Wet Mix Paver Finisher Machine

Get Best Deal

Wet Mix Paver Finisher - Steel Body, 100-250 TPH Capacity | Diesel Engine, Hydraulic Transmission, Low Maintenance Design, Enhanced Stability

EnginePowerful Diesel

MaterialHigh-Strength Steel

DimensionsVariable By Model

WeightModel Dependent

Capacity100-250 Tph

PowerHydraulic System

Wet Mix Paver

EngineKirloskar Bs-Iii

Engine Output78 Kw

Length5600 Mm

Operating Width3190 Mm

Weight10 Tons

Hopper Capacity4.25 Cubic Meters

View More

Asphalt Paver Finisher

Get Best Deal

Asphalt Cum Wet Mix Paver Finisher

Get Best Deal

Wet Mix Paver Finisher

Get Best Deal

Wet Mix Paver

Engine Power150 Hp

MaterialSteel

Dimensions10X5X3 M

Weight15000 Kg

Capacity5000 L

Fuel TypeDiesel

Mechanical Wet Mix Paver

Product TypeRoad Paver

Primary ColorRed

MaterialSteel

Power SourceEngine

DimensionsVariable

Weight1000kg

Wet Mix Paver - Mild Steel, 200 mm Laying Thickness, 300 mm Operating Height, 5 HP Engine Output, Capacity 120 to 150 ton/hr, Weatherproof & Low Noise Operation

Price Trend: 38.00 - 90.00 INR/Piece

MOQ1 Piece/Pieces

MaterialMild Steel

Top Rated Products

Wet Mix Paver - Steel, 2.5 to 4.5 Mtrs Width | High-Efficiency Mixing, User-Friendly Design, Precision Controls

Jay Khodiyar Metal Industries

FAQs Related to Wet Mix Paver

Specifications like engine output, operating height and width, paving speed, travel speed, hopper capacity, and a fuel tank capacity of wet mix pavers vary from model to model. It is, therefore, necessary to choose the right version of wet mix paver as per the budget and size of the paving project.

To extend the longevity of the wet mix paver, its hardware -parts, and components should go through regular checking procedures. One should verify whether its hydraulic system, screed, and vibratory compactor are functioning properly or not. Importance needs to be given to checking the hydraulic fluid storage level of this equipment. In case there is a blockage in its internal parts, immediate action needs to be taken to handle the situation. Operating speed and paving direction are the other two factors that one should consider while doing maintenance checking procedures.

Wet mix paver spreads dry-lean concrete by combining higher aggregate and lower cement content to attain a specific texture of the granular sub-base layer. Spreading of graded, crushed and granular aggregate-based macadam is another task that it performs with utmost precision. The thickness of the spread concrete layer depends on the slope specifications of a particular surface. The vibratory compactor of the wet mix paver plays a significant role in attaining the perfection of the finished surface.

Wet mix paver handles wet cast concrete that has a liquid-based texture. Due to its high slump rate, one can pour wet mix concrete directly from the truck or the hopper or mixer. A dry mix paver is suitable for handling dry cast concrete with slump-free content for the presence of a minimal amount of water in it. Wet mix pavers and dry mix pavers have applications in residential projects. But for large-scale commercial projects, a dry mix paver is suitable for its higher strength and better load capacity than a wet mix paver.

Wet Mix Paver - Economical Wet Mix Macadam & Dry Lean Concrete Laying Solution | Versatile, Reliable, Compliant with M.O.S.T. Specifications

Product DescriptionThe Wet Mix Paver is the most economical and efficient solution for laying Wet Mix Macadam and Dry lean concrete in line with M.O.S.T. specifications Simple in Construction Versatile and reliable W.M.M. Paver is the most popular paver

Try Pae Mix

Product TypeBio-pesticide

FormulationLiquid

Active IngredientsTrichoderma, Paecilomyces

CFU10^8

Packaging250ml bottle

StorageCool, dry place

Wet Mix Paver Rental Service

Product DescriptionBeing a customers centric organization, we are involve in providing Wet Mix Paver Rental Service in Kolkata, West Bengal, India. These paver are made using quality checked components and latest technological standards. Our Wet Mix Paver are used in the construction of roads. To get full customers sa

Sana Diamond Engi-mech Llp

Ahmedabad

Deals in:

Rudra Engineers

Ahmedabad

Deals in:

A.K Engineering

New Delhi

Deals in:

Js Brand

Delhi

Deals in:

Hitech Road Equipments

Mehsana

Deals in:

S K Engineering

New Delhi

Deals in:

Universal Engineers

Ahmedabad

Deals in:

Himalaya Engineering Co.

Mehsana

Deals in:

Kishan Industries

Ahmedabad

Deals in:

Aadesh Industries

Mehsana

Deals in:

Gajjar Equipments Pvt Ltd

Ahmedabad

Deals in:

Cheharkrupa Engineers

Ahmedabad

Deals in:

Latest from Wet Mix Paver

Wet Mix Paver Finisher

By:

Unipave Engineering Products

Wet Mix Paver Finisher In Delhi Sk Engineering

By:

S K Engineering

Wet Mix Paver Finisher Machine With Power Steering 4 Cubic Meter Hopper Capacity

1900000 INR

By:

Vishwas Equipment

Semi Hydro Wet Mix Paver

By:

Moris Industries

Wet Mix Paver

By:

Maan Industries

Wet Mix Paver

By:

D. M. Overseas

Wet Mix Paver: An Overview

A wet mix paver is a road construction equipment that plays a crucial role in creating and maintaining plain and smooth surfaces of highways, airport runways, and other concrete surfaces. This road construction equipment is useful for applying layers of dry-lean concrete ( it combines aggregate and cement in a 14:1 ratio) for preparing the GSB surface. It is also instrumental in laying wet mix macadam (graded, crushed, and granular aggregate which is mixed with water in specific proportion to attain a dense texture). The mixture is laid and spread on the granular sub-base layer (GSB) one or multiple times to achieve the desired surface of roads. The design and mechanism of a wet mix paver conform to MoRTH (Ministry of Road Transport & Highways, Government of India).

How does a wet mix paver work?

Automatic or semi-automatic wet mix paver consists of several units and each of these units has a significant role in its smooth running. To understand its operating process, one should have a clear understanding about its standard components and their roles.

1. Based on the project requirement, this road construction equipment is available in diesel-fueled or water-cooled engines of specific horsepower along with an electrical starting system.

2. Its hydraulic hopper is useful for the transportation of asphalt concrete to its conveyor.

3. Its twin bar conveyors are instrumental in feeding the material to its augers from the hopper.

4. Power steering of this road construction equipment simplifies its controlling procedures. All the parameters of this equipment are controllable from its single dashboard for the convenience of the operator.

5. Hydraulic telescopic screed of wet mix paver helps to maintain the specific thickness of asphalt -concrete -layer by precisely removing excess material.

6. Chassis of this road construction equipment strengthens its structure and improves its stability.

Usually, for spreading the first layer of asphalt concrete, a motor grader is the ideal choice. Its hydraulic blade is capable of adjusting the thickness of the wet mix macadam layer as per the slope of a specific surface. Its design includes loading hoppers, a material distribution unit, and a compaction-controlling section to attain flawless texture of the finished surface.

The wet mix paver starts its compaction process by using a vibratory compactor immediately after the completion of lying layers of wet mix macadam. Width-by-width movement of the vibratory compactor is maintained from the lower edge to the upper edge of the applied WMM layer. The second layer of wet mix macadam is spread only after checking the quality of the first WMM layer. The final compaction of the WMM surface takes around 24 hours to dry.

Types of Wet Mix Pavers

Wet mix pavers are available in different models with various specifications. Parameters like travel speed, screed design, operating width, fuel tank capacity, and other attributes of these road construction machines vary as per their design. These include:

1. Semi-automatic Wet Mix Paver Finisher

This road construction equipment features noiseless operation. Its advanced features include-

a. Hydraulically controlled telescopic screed for precise removal of excess WMM material to maintain the required thickness of the spread layer

b. Power steering and air brake-based design

c. Single dashboard-based operation controlling arrangement

2. Semi-automatic Asphalt Cum Wet Mix Paver Finisher

This version of the wet mix paver is suitable for WMM and bitumen-spreading purposes. It uses LPG fuel or an oil-based burner as the source of heat of its screed for maintaining homogeneity and a standard thickness of the applied layer.

3. Semi Hydro Wet Mix Paver

This version of wet mix paver operates semi-hydraulically to precisely control the paving process.

Applications of Wet Mix Pavers

Wet mix pavers have a broad scope of applications. These road construction equipment are suitable for constructing roads, highways, driveways, walkways, and sidewalks. The specialty of wet mix pavers is that these equipment maintain high precision while preparing wet mix macadam. Specific proportion is maintained while blending water, graded and crushed aggregates, and cement to attain desired texture of the spread layer post-compaction. The aesthetics of developed roads and driveways is another important factor that wet mix pavers help to achieve and maintain.

Advantages of Using A Wet Mix Paver

Wet mix paver is effective in constructing roads, commercial parking areas, residential parking spaces, airport runways, warehouse floors, factory floors, and highways with improved surfaces. There are several advantages to this road construction equipment. These are mentioned below:

1. Its user-friendly mechanism not only boosts its productivity but also upgrades the standard of construction.

2. This road construction equipment maintains high accuracy in maintaining the proportion of raw materials and their mixing to achieve the desired result.

3. It can be relocated to different construction sites.

4. High output of wet mix paver ensures higher return in any construction project at minimal investment.

5. Hardware -parts of this equipment are made as per global manufacturing norms.

6. Lubricated components of this equipment help to minimise their downtime rate.

Client Testimonials & Reviews

RaviParekh

UNIVERSAL ENGINEERS

We would like to introduce our company as "Universal Engineers" manufacturer and exporters of Road Construction Machinery. Since last 3 years we had under taken services of "Tradeindia.com" and start getting immediate responses from prospective customers from India and Abroad. Your creative catalog hosting and allied services like call me free, sms and trust Stamp, banner, language converter for 10 different countries are proving exclusive to us and creates an elite image of our company as tech-savvy and customer friendly company. Moreover, keywords for inquiries of our products are prompting our buyers to directly attract to our catalogue / website and thus, creates an direct / indirect pull in to Internet World Market with respect to our products. We look forward to reap more benefits in coming time to enable us share you some more with association with TradeIndia.com.

Wet Mix Paver Price List

Product Name | Expected Price |

|---|---|

| Wet Mix Macadam Plant | 2000000 |

| Wet Mix Paver | 2500000 |

| Apollo Wet Mixing Paver | 2200000 |

| WM-6 Wet Mix Paver | 2500000 |

| Crawler Mounted Sensor Paver Finisher | 2000000 |

| Asphalt cum Wet Mix Paver Finisher | 1950000 |

| Sensor Paver | 2000000 |

| Mechanical Wet Mix Paver | 2000000 |

| Wet Mix Paver Finisher | 2200000 |

This Data was Last Updated on 2025-08-31

Wet Mix Paver Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Himalaya Engineering Co. Mehsana, India | 20 Years |

Kesar Road Equipments ( India ) Pvt. Ltd. Mehsana, India | 14 Years |

Universal Engineers Ahmedabad, India | 13 Years |

Unipave Engineering Products Ahmedabad, India | 12 Years |

S K Engineering New Delhi, India | 7 Years |

Rudra Engineers Ahmedabad, India | 5 Years |

A.k Engineering New Delhi, India | 5 Years |

Jay Khodiyar Metal Industries Ahmedabad, India | 4 Years |

Sana Diamond Engi-mech Llp Ahmedabad, India | 4 Years |

Lal's Exporters (india) Private Limited Patna, India | 2 Years |

Upcoming Tradeshows

ENGIMACH 2025

Wed, 03 Dec, 2025 - Sun, 07 Dec, 2025

China (Guzhen) International Lighting Fair 2025

Wed, 22 Oct, 2025 - Sat, 25 Oct, 2025

India Med Expo Hyderabad 2025

Fri, 05 Dec, 2025 - Sun, 07 Dec, 2025

YARNEX - Mumbai 2025

Thu, 27 Nov, 2025 - Sat, 29 Nov, 2025

Spectra Expo 2026

Thu, 05 Feb, 2026 - Sat, 07 Feb, 2026

INDIA GREEN ENERGY EXPO 2026

Wed, 29 Jul, 2026 - Fri, 31 Jul, 2026

Dairy Expo 2025

Thu, 11 Dec, 2025 - Sat, 13 Dec, 2025

Dahej Industrial Expo 2025

Wed, 12 Nov, 2025 - Fri, 14 Nov, 2025

Paper India Expo 2026

Mon, 13 Apr, 2026 - Wed, 15 Apr, 2026

WOOD ASIA 2026

Fri, 16 Jan, 2026 - Mon, 19 Jan, 2026

Popular Categories