- Tradeindia

- Engine, Engine Parts & Mounts

- Dry Cylinder Liner

Dry Cylinder Liner

(71 products)Line Drying Time Recorder - Six Samples Capacity, 50x30x15 cm | Simultaneous Testing at Four Speeds (6-12-24-48 hrs) with 110-240V Power Supply

Sample CapacitySix samples

Speed SettingsFour speeds

Drying Time Range6-48 hours

Power Supply110-240V

Dimensions50x30x15 cm

Weight10 kg

Caltech Engineering Services

Mumbai

Trusted Seller

Trusted Seller Premium Seller

Premium Seller21 Years

Metal Cylinder Liner Mercedes Om 422 Om 423 Om 424

Price Trend: 630.00 - 900.00 INR/Piece

MOQ10 Piece/Pieces

Parts NameOther

MaterialMetal

View More

Superior Grade Dry Cylinder Liners

Get Best Deal

DRY CYLINDER LINERS / SLEEVES

Get Best Deal

Cylinder Liners Application: Used In Automotive Engines

MOQ300 , Piece/Pieces

ApplicationUsed in Automotive Engines

Warranty1 Year

Cylinder Liner - Application: Automobile

Price: 600 INR/Piece

MOQ5 Piece/Pieces

Product TypeMotorcycle Engine Part

Parts NameEngine Mounts

MaterialAluminum, Iron, Steel, Metal

ApplicationAutomobile

Dry Cylinder Liner - Aluminum | Wear Resistant, Corrosion Resistant, Heat Resistant, Precision Engineered, Smooth Finish, Lightweight Design, Crack Resistant, Enhanced Durability

Price: 500 INR/Piece

MOQ2000 Piece/Pieces

Product TypeOther, Dry Cylinder Liner

MaterialAluminum

ApplicationIndustrial

Warranty2 Year

Cylinder Liner & Assembly

MaterialNA

DimensionsNA

AssemblyIncluded

PartsMultiple

CompatibilityAccel-Sabroe

ApplicationCompressor

440 V Automatic Multi Cylinder Drying Range Machine For Textile Industry Drop Earrings

MOQ1 Unit/Units

Product TypeTextile Machinery

MaterialSteel

Machinery TypeBleaching Machine

Voltage440 Volt (v)

ColorGrey

SIMPSON ALL SERIES - Cylinder Sleeve 005 | Gray, Polished Finish for Auto Industry Application

Price: 90 INR/Piece

MOQ100 Piece/Pieces

Product TypeCylinder Liner

Casting MaterialOther

ApplicationAuto Industry

Surface TreatmentPolished

ColorGray

102 Mm 71 Mm Round Stainless Steel Dry Cylinder Liner For Two Wheeler - Stainless Steel, 102 Mm Length, 71 Mm Stroke, Rounded Head, Smooth Lubricant Flow

Price: 120 INR/Piece

MOQ834 Piece/Pieces

Product TypeMotorcycle Engine Part

Parts NameEngine Mounts

MaterialSteel

ApplicationTwo Wheeler

Size102 mm

Stroke71 mm

17.4 x 11.4 inches Iron Engine Mount - OE Number 240-1002021, Designed for Diesel Power Applications with Head Gasket Lip

Price: 355 INR/Piece

MOQ300 Piece/Pieces

Product TypeDry Cylinder Liner, Other

Parts NameEngine Mounts

MaterialIron

ApplicationAutomotive

OE Number240-1002021

Size17.4 x 11.4 inch

Drying Cylinder Liner

MaterialSteel

DimensionsVariable

HeatingSteam

PressureVariable

FinishPainted

WeightVariable

PLC. Control Multi Cylinder Drying Range

Roller Face1600-3000mm

Cylinder Dia760mm

Design Pressure4-5 bar

Design Temperature150 C

Shell MaterialAISI SS304

Shell Thickness2.5mm

Top Rated Products

FAQs Related to Dry Cylinder Liner

Who are the top dry cylinder liner manufacturers in India?

- Caltech Engineering Services

- Aeco Engineering Co

Which cities have the largest number of dry cylinder liner suppliers?

- Delhi

- Mumbai

- Jaipur

- Rajkot

- Ahmedabad

- Bhavnagar

- Agra

- Gurugram

- Coimbatore

- Surat

- Vapi

- Dubai

What is the price range for dry cylinder liner offered by listed companies?

| Company Name | Currency | Product Name | Price |

|---|---|---|---|

| SUPER POWER INDUSTRIES | INR | Cylinder liner | 600 |

| R. R. Industries | INR | 17.4 x 11.4 inches Dry Cylinder Liner | 355 |

| PLAZA AUTO CAST | INR | 102 Mm 71 Mm Round Stainless Steel Dry Cylinder Liner For Two Wheeler | 120 |

| GANESH AUTO INDUSTRIES | INR | 7 Inches Round Head Metallic Dry Cylinder Liner For Automobile Industry | 480 |

| SNM ENGINEERING | INR | Dry Cylinder Liner | 150 |

| GLOBAL LINERS | INR | alusil cylinder liners | 200 |

How many trusted sellers are available for dry cylinder liner?

- CALTECH ENGINEERING SERVICES

What is the minimum order quantity for dry cylinder liner?

Do listed companies have registration & certifications?

- CALTECH ENGINEERING SERVICES

- AECO ENGINEERING CO

- GARIMA GLOBAL PVT. LTD.

- GUJARAT PRECISION

- Benchmark Liners

- Jay Metal

- GANESH AUTO INDUSTRIES

What is the get latest price feature?

What types of payment methods are accepted by the dry cylinder liner suppliers?

Dry Cylinder Liner

MaterialSteel

DimensionsVariable

FinishAs per requirement

SizeVehicle standard

ManufacturingIn-house

Minimum order1000pcs

Dry Cylinder Liners

MaterialCast Iron

DimensionsVaried

Bore FinishMultiple

Surface TreatmentMultiple

HardnessSpecific

ToleranceHigh Precision

Steel Dry Cylinder Liner For Automotive Industry, Hard Structure And 30 Mm Thickness

MOQ10 Piece/Pieces

Product TypeDry Cylinder Liner , Other

MaterialSteel

ApplicationAutomotive Industry

Size30 mm

Orange And Green Thin Wall Dry Liner

MaterialSteel

Wall thickness0.5-2mm

Diameter50-200mm

Height100-300mm

Surface finishRa 0.4µm

Manufacturing processCasting, Machining

Dry Cylinder Liner - Cast Iron, Various Bore Diameter, Customizable Length | High Dimensional Accuracy, Sturdy Design, Affordable for Internal Combustion Engines

MaterialCast Iron

DimensionsVaried

Surface FinishHoned

Bore DiameterCustomizable

Wall ThicknessVariable

HardnessHigh

Metallic Dry Cylinder Liner - Round Head, Various Sizes | Easy Replacement for Automobile Industry

Price: 480 INR/Piece

MOQ100 Piece/Pieces

Product TypeOther, Head Metallic Dry Cylinder

MaterialMetal

ApplicationFor Automobile Industry

OE NumberNo

SizeComes in various sizes

WarrantyNo

Hydraulic Pump - Cast Iron, 100mm Diameter x 200mm Length, 80mm Bore Diameter, 10mm Wall Thickness, Superior Performance & Quality Assurance

Price Trend: 70000.00 - 600000.00 INR/Unit

MOQ1 Piece/Pieces

Supply Ability100 Per Month

Delivery Time7 Days

Main Export Market(s)Western Europe, North America, Central America, Africa, Eastern Europe, Middle East, South America, Asia, Australia

Dry Cylinder Liners - Quality Raw Material Fabrication | Durable, Sturdy, Corrosion Resistant

MaterialRaw Material

DurabilityHigh

SturdinessHigh

ResistanceCorrosion

Vendor SourcedReliable

FabricationManufacturers

Dry Cylinder Liner - Aluminium Alloy, Compact Design with Easy Installation

MaterialAluminum Alloy

DimensionsVaried

Surface FinishSmooth

Manufacturing ProcessCasting

HardnessHigh

TolerancePrecise

Automotive Engine Dry Cylinder Liners

Product TypeOther, Dry Cylinder Liners

Parts NameOther, Engine Spare Parts

MaterialIron

ApplicationAutomobile Industry

Dry Cylinder Liner - Metal, Steel | Application: Engine, Designed for Heavy, Medium, and Light Applications with Expert Engineering Support

Price: 150 INR/Carton

MOQ1000 Carton/Cartons

Product TypeCar Engine Part

Parts NameEngine Mounts

MaterialSteel, Metal

ApplicationEngine

View More

Dry Cylinder Liner for Automobile

Price : 140 INR

Industrial Dry Cylinder Liner

Get Best Deal

Durable Dry Cylinder Liner No Assembly Required

Price : 160 INR

Top Grade Dry Cylinder Liner

Price : 120 INR

High Quality Dry Cylinder Liner

Price : 130 INR

Cylinder Liner

MaterialHardened Steel

DimensionsVary by model

Surface FinishRigid

ManufacturingPrecision Machined

CoatingPhosphated

ApplicationsDiesel Engines

Glazed Cylinder Liners

MaterialCast Iron

Diameter Range50-150mm

Length Range100-300mm

Surface FinishRa 0.4µm

Hardness550HV

UsageInternal combustion engines, various applications.

View More

Wet And Dry Cylinder Liner

Get Best Deal

Dry Cylinder Liners

Get Best Deal

View More

Dry Tractor Cylinder Liners

Get Best Deal

Latest from Dry Cylinder Liner

7 Inches Round Head Metallic Dry Cylinder Liner For Automobile Industry

480 INR

By:

Ganesh Auto Industries

Dry Cylinder Liner For Automotive Industry, Hard Structure And 30 Mm Thickness

By:

Sky Metal Industries

Dry Cylinder Liners In Hard Structure And Cylindrical Shape, Thickness 30 Mm

By:

Winner Auto India

Dry Cylinder Liner

By:

Garuda Impex

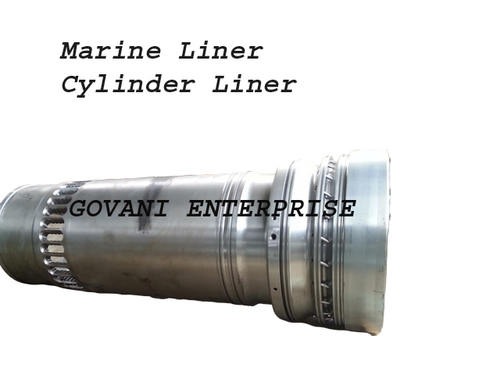

Dry cylinder liners are a cylindrical part fitted into an engine block to form a space in which the piston can reciprocate smoothly. Unlike wet liners, these do not come in direct contact with the engine's coolant. Generally these are made from cast iron or cast steel alloyed with chromium, copper or nickel.The aforementioned alloying elements help resist corrosion and also increase the wear resistance of the liners at higher temperatures.

Dry cylinder liners are manufactured separately from the cylinder block. This is necessitated due to the fact that since the liner needs to be comparatively more sturdy than the cylinder block, hence it's made from a comparatively superior quality material, that too with optimum precision. Since dry liners are used in a wide range of engines, these are manufactured in various specifications and dimensions, with the option of customization also available.

Types of Dry Cylinder Liners

Thin Walled Dry Cylinder Liners a Makes the engine lighter and more compact.

Loose-fit Dry Cylinder Liners a These are distinguished by the gap between the inner circumferential surface of the bore of the cylinder block and the outer circumferential surface of the liner.

Tight-fit Dry Cylinder Liners a These have no gaps between the aforementioned inner circumferential surface and the outer circumferential surface.

Advantages of Dry Cylinder Liners

These are very simple to install and service.

These ensure that there is no danger of water leakage either in to crankcase or the combustion chamber.

Due to the absence of heavy flanges at the top of these liners, cylinder centers can be reduced.

Their design ensures optimal cooling of their upper part.

Usage Preferences of Dry Cylinder Liners Amongst Manufacturers

Dry cylinder liners are preferred by Asian, African and North American manufacturers, most notable being general motors, Toyota etc. As for Europe, dry liners are still the second choice there. The reason for this dichotomy is just plain old usage habits of different manufacturers in different parts of the world.

However, it must also be noted that European manufacturers are gradually realizing the benefits of dry liners and thus have started to use these liners in their engine blocks. Although dry liners replacing wet liners altogether is still a far fetched idea, yet their usage is almost certain to increase in the coming years.

Dry Cylinder Liner Price List

This Data was Last Updated on 2025-11-10

Dry Cylinder Liner Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Caltech Engineering Services Mumbai, India | 21 Years |

Aeco Engineering Co Mumbai, India | 4 Years |

Upcoming Tradeshows

International Crop Science Conference and Exhibition 2026

Mon, 19 Jan, 2026 - Tue, 20 Jan, 2026

India Food Pack Expo 2026

Tue, 20 Jan, 2026 - Thu, 22 Jan, 2026

Asia Labex 2025

Thu, 13 Nov, 2025 - Sat, 15 Nov, 2025

Vyapaar Expo 2026

Fri, 30 Jan, 2026 - Sun, 01 Feb, 2026

The Harit Bharat Expo 2026

Fri, 16 Jan, 2026 - Sun, 18 Jan, 2026

Power On 2026

Fri, 23 Jan, 2026 - Sun, 25 Jan, 2026

SVUM 2026 INTERNATIONAL TRADE SHOW

Wed, 11 Feb, 2026 - Fri, 13 Feb, 2026

Automechanika Dubai 2025

Tue, 09 Dec, 2025 - Thu, 11 Dec, 2025

CIFF - China International Furniture Fair Guangzhou 2026

Wed, 18 Mar, 2026 - Sat, 21 Mar, 2026

ET TECH X 2025

Thu, 11 Dec, 2025 - Sat, 13 Dec, 2025

Popular Categories