- Tradeindia

- Packaging Machine

- Automatic Punching Machine

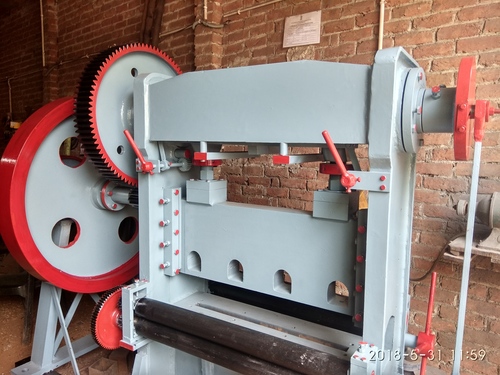

Automatic Punching Machine

(325 products)Hydraulic Punching Machine Mx340 - Body Material: Steel

Price: 990922 INR/Piece

MOQ1 Number

ColorRed

Usagepunching & Shearing

Body MaterialSteel

Size700 X 800

TypeOther

StructureFixed

Ga-mor Machine Tools Pvt. Ltd.

Bengaluru

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller Premium Seller

Premium Seller12 Years

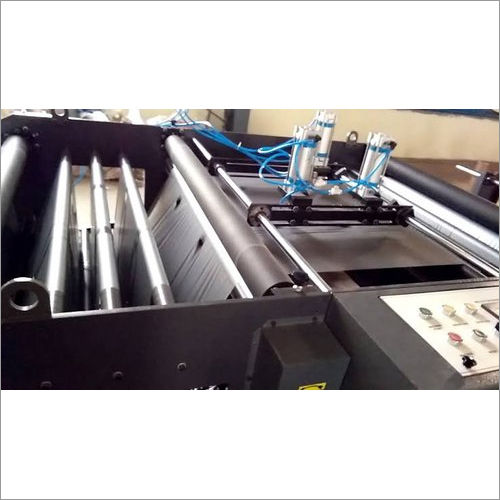

Industrial Mulch Film Punching Machine - Automatic Grade: Automatic

Price: 1650000 INR/Unit

MOQ5 Unit/Units

UsageIndustrial

Product TypeIndustrial Mulch Film Punching Machine

MaterialMetal

ComputerizedNo

Automatic GradeAutomatic

Control SystemPLC Control

Dnd Machinery Private Limited

Ahmedabad

Trusted Seller

Trusted Seller Super Premium

Super Premium Super Seller

Super Seller4 Years

View More

Mulching Hole Making Machine - Automatic Grade: Automatic

Price : 1500000.0 INR

Automatic Hole Punching Machine - Color: Black

Price : 550000 INR

Agricultural Mulch Film Punching Machine - Automatic Grade: Automatic

Price : 951000 INR

Automatic Mulch Film Punching Machine - Feature: Less Power Consumable

Price : 4500000.0 INR

Electric Mulch Film Punching Machine - Automatic Grade: Automatic

Price : 2351000.00 INR

Mulch Film Hole Punching Machine - Automatic Grade: Automatic

Price : 1851000 INR

D - Cut Punching Machine Capacity: 15 Pcs/Min

Price: 80000 INR/Unit

MOQ1 Unit/Units

TypePunching Machine

MaterialKraft paper bag

Capacity15 Pcs/min

ComputerizedNo

Control SystemFrequency Speed Control

Cutting Size3

Unique Fluid Controls

Coimbatore

Trusted Seller

Trusted Seller Super Premium

Super Premium Premium Seller

Premium Seller8 Years

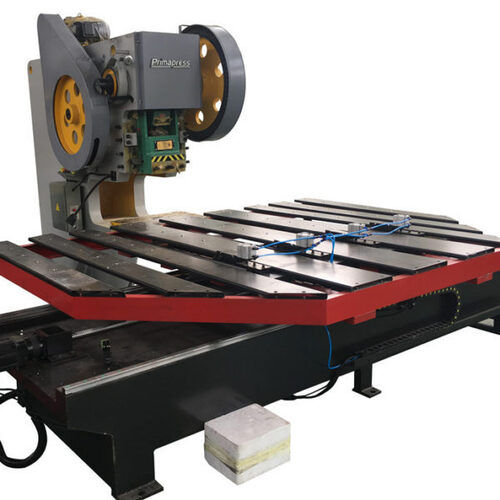

Power Press Automatic Punching Line Power Source: Diesel

MOQ1 Unit/Units

Power SourceDiesel

Operating TypeAutomatic

Surface TreatmentPainted

WarrantyYes

Usage & ApplicationsIndustrial

Nanjing Prima Cnc Machinery Co., Ltd.

Nanjing

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller4 Years

Sheet Metal Punching Machine With Automatic Feeder

Product TypeOther, Sheet metal Punching machine

Operating TypeAutomatic

ColorOff white

Usage & ApplicationsIndustrial

Maanshan Prima Cnc Machinery Co Ltd.

Maanshan

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller7 Years

View More

Automatic Punching Line Power Press Punching Machine

Price Trend : 600.00 - 6000.00 USD ($)

Heavy Duty Pneumatic Automatic Punching Machines

Get Best Deal

Automatic CNC Steel Metal Punching Machine

Get Best Deal

5 mm Coil Sheet Press Automatic Feeding Line with Uncoiler 160 Ton Punching Machine

Price Trend : 600.00 - 6000.00 USD ($)

Automatic Punching Machine - Electric, 1440 RPM | Blue-White Coated, Automatic Operation, 1 Year Warranty, Industrial Usage

Price: 75000 INR/Piece

MOQ1 Piece/Pieces

ColorBlue-White

Power SourceElectricity

Operating TypeAutomatic

Surface TreatmentCoated

Warranty1 Years

Usage & ApplicationsIndustrial

Disposable Machinery

Kolkata

Trusted Seller

Trusted Seller Super Seller

Super Seller11 Years

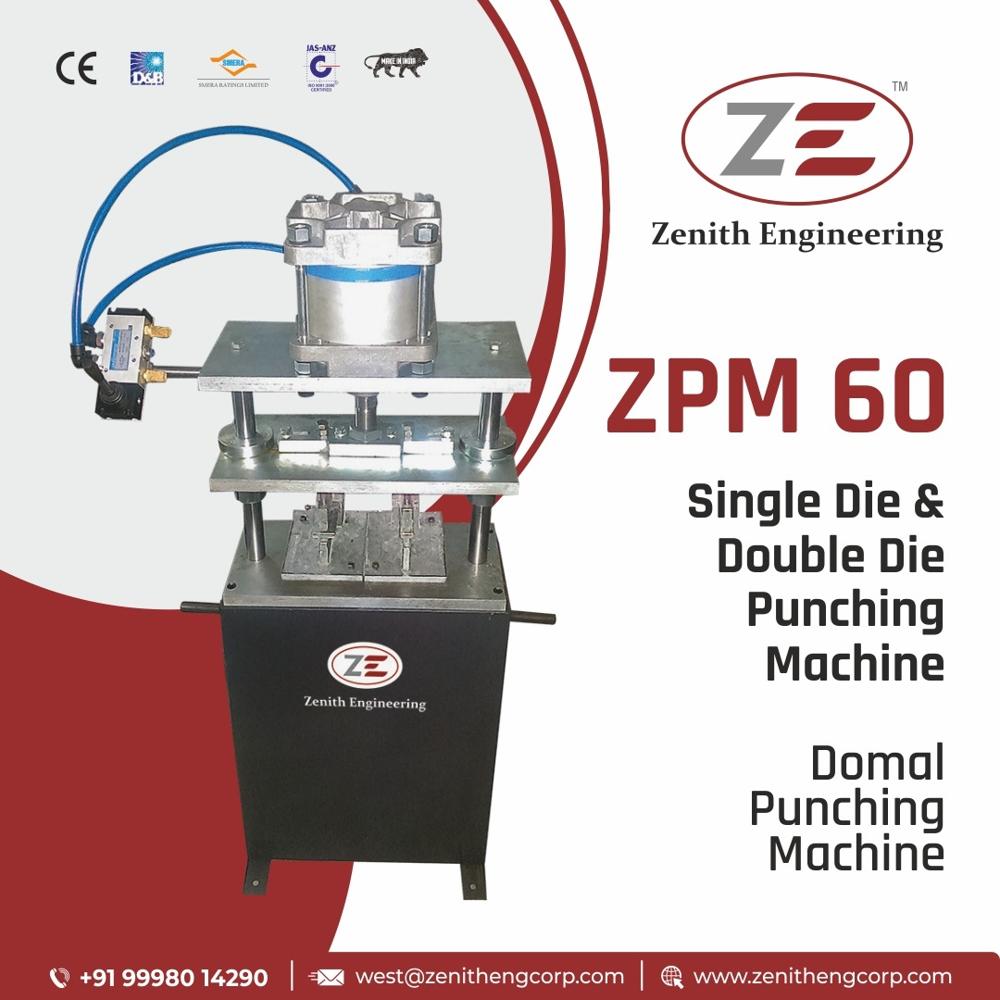

Semi-Automatic Corner Joints Punch Machine

Price: 95000 INR/Piece

MOQ1 Piece/Pieces

ColorBlack

Product TypeCorner Joints Punch Machine

MaterialMild Steel

ComputerizedNo

Automatic GradeSemi-Automatic

Voltage220 Volt (v)

Zenith Engineering And Equipments Private Limited

Vadodara

Trusted Seller

Trusted Seller Premium Seller

Premium Seller11 Years

View More

Semi-Automatic Domal Aluminium Punching Machine

Price : 95000 INR

Semi-Automatic Domal Punching Machine

Price : 95000.0 INR

Semi-Automatic Aluminium Pneumatic Punching Machine

Price Trend : 50000.00 - 300000.00 INR

Semi-Automatic Window Punching Machine

Price : 95000 INR

Semi-Automatic Pneumatic Punching Machine

Price : 85000 INR

White Automatic Cotton Filter Punching Machine

Price: 555000 INR/Piece

MOQ1 Piece/Pieces

ColorWhite

Product TypeTextile Machinery

MaterialMetal

Voltage220-380 Volt (v)

Power4.5 Watt (w)

Dimension (L*W*H)3000x900x1900 Millimeter (mm)

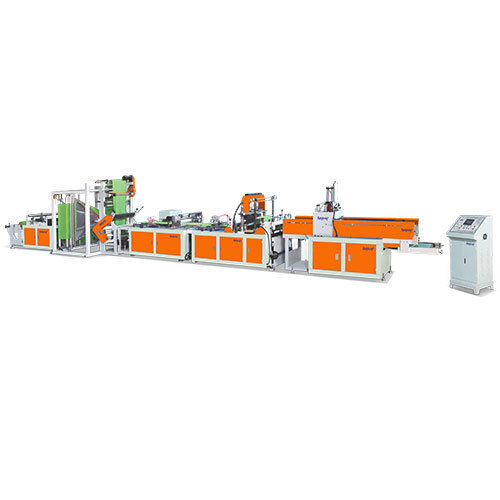

Automatic T-Shirt Bag Mouth Punching Machine - General Use: Industrial

MOQ1 Unit/Units

Product TypeAutomatic Punching Machine

General UseIndustrial

Automatic GradeAutomatic

Voltage220-240 Volt (v)

Warranty1 Year

Kamtronics Technology Private Limited

New Delhi

Trusted Seller

Trusted Seller11 Years

Black Industrial File Punching Machine

Price: 75000 INR/Unit

MOQ1 Unit/Units

ColorBlack

Power SourceElectricity

Operating TypeAutomatic

Surface TreatmentCoated

WarrantyYes

Usage & ApplicationsIndustrial

Vinpat Machinery (opc) Private Limited

Lucknow

Trusted Seller

Trusted Seller Premium Seller

Premium Seller5 Years

Aluminium Cleat Punching Machine - 370x370x1320 mm, Blue | 1.4 Ton Pneumatic Punching Force, 4 Position Profile Capability, Foot Paddle Operation

Price: 125000.0 INR/Piece

MOQ1 Piece/Pieces

ColorBlue

Product TypeAluminium Cleat Cutting Machine

General UseIndustrial

MaterialAluminum

TypeVertical

Weight (kg)110 Kilograms (kg)

Taalin Machinery & Robotics Pvt. Ltd.

Greater Noida

Trusted Seller

Trusted Seller Premium Seller

Premium Seller5 Years

Bullet Punching Machine

MaterialSteel

DimensionsVariable

PowerElectric

WeightHeavy

CapacityHigh

Warranty1 Year

FAQs Related to Automatic Punching Machine

A sensor is a

device that receives and responds to a signal when the machine is on. The

signal indicates how much the output of sensor changes if the input quantity

changes. In this machine, sensor plays a crucial role in automation completing

certain characteristics such as flexibility, rationalization, cost reduction,

and environmental protection.

In the manual

method of punching, the disadvantages include angular misalignment of the

sheet, higher material handling time, manufacturing time, and reduced safety

for the workers.

The automatic

punching machine works like doing hole in punching paper. The punch tends to

press the paper against the support of the hole and then into a round opening.

The scrap from the punching is gathered in the container.

A high-performance

automatic punching machine tends to process and work on high-strength stainless

steel to produce quality products.

The basic frame of

the automatic punching machine is a high-strength die-cast part that tends to

absorb resonances and vibrations. It is also transfer resonances and vibrations

into the foundation.

Auto Punching Machine - Color: Black

Price: 750000 INR/Unit

MOQ1 Unit/Units

ColorBlack

UsageIndustrial

Power SourceHydraulic

ConditionNew

SizeDifferent Size

Voltage220-240 Volt (v)

Automatic U And W Cut Offline Punching Machine

MOQ1 Piece/Pieces

Product TypeU and W Cut Offline Punching Machine

General UseIndustrial

Automatic GradeAutomatic

Drive TypeElectric

ColorBlue/Gray

U Cut Carry Bag Punching Machine - Automatic Grade: Fully Automatic

Price: 100000 INR/Unit

MOQ1 Unit/Units

ColorBlue White

Product TypeU Cut Punching Machine

General UseIndustrial

Automatic GradeFully Automatic

Drive TypeElectric

ComputerizedNo

Hydraulic Punching Machine - Automatic Grade: Automatic

Price: 195000.0 INR/Unit

MOQ1 Unit/Units

ColorRed

Product TypeHydraulic Punching Machine

MaterialMild Steel

Automatic GradeAutomatic

Control SystemFrequency Speed Control

Voltage220 Volt (v)

Semi-Automatic Paper Punching Machines

Motor3 Phase 1.5 HP

Punching Speed700-800 strokes/hour

Sheet Capacity1/8" (3mm)

Working Length25"

OperationFoot Pedal

MaterialSteel

View More

Use Efficient Semi-Automatic Paper Punching Machines for

Price : 350000 INR

Industrial Automatic Punching Machine

MaterialSteel

DimensionsCustomizable

Power220V

SpeedVariable

CapacityHigh

WeightHeavy

Agarwal Trafin Private Limited

Kolkata

Trusted Seller

Trusted Seller Premium Seller

Premium Seller6 Years

View More

Automatic Punching And Die Cutting Machine

Get Best Deal

Flat Bed Punching Machine

MOQ1 Unit/Units

Auxiliary Packaging Machine TypeCleaner

ComputerizedYes

Automatic GradeSemi-Automatic

Control SystemHuman Machine Interface

Drive TypeElectric

Power200 Watt (w)

Mano Industrial Machine Tools

Chennai

Trusted Seller

Trusted Seller Premium Seller

Premium Seller9 Years

View More

Manual Paper Cutting Machine - 26" & 32" Sizes | Motorized with Dual Knives, All Standard Accessories

Get Best Deal

Electric Binding Machine - Metal, Binding Capacity: 250-500 Sheets, Punching Speed: 12-15 Sec/Time | Semi-Automatic, Electric Punching Form, Back Space Adjust, 12 Month Warranty

Price Trend : 55000.00 - 190000.00 INR

Automatic Corrugated Die Punching Machine

Get Best Deal

Silver Semi Automatic Heavy Duty Die Punching Machine

Price : 840000 INR

Automatic Heavy Duty Die Punching Machine

Price Trend : 500000.00 - 4000000.00 INR

Industrial Cable Tray Punching Machine - Color: Blue

Price: 600000.0 INR/Unit

MOQ1 Set/Sets

ColorBlue

Power SourceElectricity

Operating TypeSemi Automatic

Surface TreatmentPainted

Warranty1 year

Usage & ApplicationsIndustrial

View More

Speaker Jali Punching Machine - Automatic Grade: Manual

Price : 550000 INR

Metal Sheet Punching Machine - Stainless Steel, 220-240 Volt | Semi-Automatic, Human Machine Interface, Eco-Friendly, Precision Punched Holes

Price : 700000 INR

Cable Tray Sheet Punching Machine - Operating Type: Automatic

Price : 400000 INR

Ceiling Panel Punching Machine - Automatic Grade: Semi-Automatic

Price : 300000 INR

Hydraulic Punching Machine - Mild Steel, 220 Volt Operational Efficiency | Industrial Use, Precision Engineering, Heavy Duty Design

Price: 250000.00 INR/Unit

MOQ1 Unit/Units

Product TypeHydraulic Punching Machine

General UseIndustrial

MaterialOther, Mild steel

ComputerizedNo

Voltage220 Volt (v)

Koneet Industries Private Limited

Hyderabad

Trusted Seller

Trusted Seller3 Years

Automatic Metal Sheet Punching Machine Warranty: Yes

Price: 948000 INR/Unit

MOQ1 Unit/Units

Product TypeAutomatic Metal Sheet Punching Machine

MaterialMetal

Automatic GradeAutomatic

Control SystemHuman Machine Interface

WarrantyYes

Giriraj Press Tech Automation

Rajkot

Trusted Seller

Trusted Seller Premium Seller

Premium Seller3 Years

Carton Punching Machine - Automatic Operation, Electric Drive Type | Ideal for Industrial Applications, Brand New

Price: 900000 INR/Unit

MOQ1 Unit/Units

TypeOther, Carton Punching Machine

FeatureOther

Automatic GradeAutomatic

Drive TypeElectric

View More

Carton Punching Machine - Feature: Automatic Circulation

Price : 5000000 INR

White And Purple Cup Stock Roll Punching Machine

Price: 2800000 INR/Piece

MOQ1 Unit/Units

ColorWhite and Purple

MaterialStailness Steel

ComputerizedYes

Voltage220 Volt (v)

Weight (kg)150 Kilograms (kg)

Warranty1 year

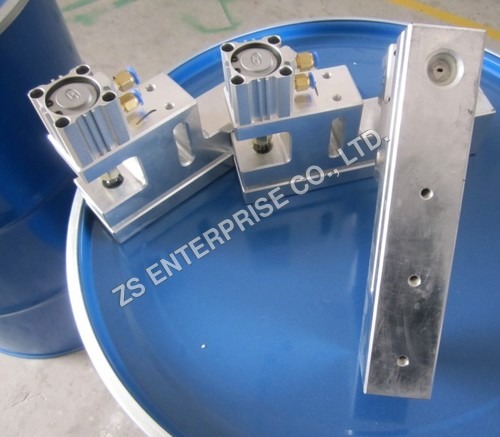

Aluminium Pneumatic D Punch Machine - Automatic Grade: Semi-Automatic

Price: 45000 INR/Piece

MOQ1 Piece/Pieces

ColorSilver

MaterialStainless Steel

FeatureDurable, Rust Proof

ComputerizedNo

Automatic GradeSemi-Automatic

Control SystemFrequency Speed Control

View More

W Cut Cary Bag Punching Machine - Automatic Grade: Semi-Automatic

Price : 65000 INR

D Cut Punching Machine - Automatic Grade: Semi-Automatic

Price : 65000 INR

Pneumatic V Notch Punch Machine

Price Trend: 120.00 - 300.00 USD ($)/Piece

MOQ1 Piece/Pieces

Machine TypeNotch Punching Machine

Operating Temperature5AdegC aEUR" 45AdegC

Lubricating SystemManual Lubrication (if required)

Cooling SystemAir Cooled

Frame TypeHeavy Duty Steel Frame

Model NoV-NOTCH-01

Pneumatic Carry Bag Punching Machine

MaterialSteel

DimensionsNA

Power1.1kw

MotorThree Phase

ControlPush Button

SwitchFoot Control

View More

Automatic D Cut Non Woven Bag Punching Machine

Price : 47000 INR

Automatic Woven Sack Bag Punching Machine

Price : 52000 INR

Carry Bag Punching Machine - Metal, 220-240V | Automatic Operation, Heavy Duty, Human Machine Interface

Price : 47000 INR

Carry Bag Punching Machine - Metal Construction | Automatic, Heavy Duty, Human Machine Interface, 220-440 Power, Warranty Included

Price : 47000 INR

Fully Automatic Carry Bag Punching Machine - Warranty: Standard

Price : 48000 INR

Heavy Duty Platen Punching Machine 1800 Sheets-Hr - Automatic Grade: Automatic

Price: 625000 INR/Piece

MOQ1 Piece/Pieces

MaterialMild Steel

Capacity8000 Sheets/hr Pcs/hr

Automatic GradeAutomatic

Control SystemPLC Control

Power5 kW Watt (w)

Warranty1 Year

Popular Automatic Punching Machine

Automation is thetechnology that involves the application of electronic, mechanical, and

computer-based systems that generate operation and control production

Automation of operation results self-generated functioning of the machine that

reduces time and human effort. Automatic Punching Machine works on the

principle of the sheet metal operations punching or pressing operation, which

takes place in the process sequence. This machine does the self-generated

punching operation. For the operation, programming is done on a PC or laptop,

which is equipped with proper software that is actually the part of the

machine. Through a graphic and menu-driven user interface the machine is set

for functioning and all the punches in a single operation are shown on the

screen.

The Automatic

Punching Machine works on the principle of press, which is designed to punch

blank sheet by applying mechanical force or pressure. The press or pressure is

exclusively applied for mass production. This is the most efficient and the

fastest way to transfigure or form a metal into a finished punched product.

This machine is meant for punching and embossing flat sheet materials to

produce featured structure or the intended design of the final product. It is

equipped with a linear die carrier and quick change tools. When the programming

is intended for the work pieces to enter length of bars, it controls them

automatically and calculates the intended number of pieces to be punched. For

example, if we intend to produce 22 pieces of a bar of 6000 mm, we have to put

this length of metal into the machine.

Working

Methodology:

The working

methodology is sequential. It begins with Start button when the machine opens,

which is followed by cylinder mounted sensor input. Then the loading cylinder

operation occurs, which is followed by loading cylinder mounted sensor input.

Next functioning is unloading cylinder operation followed by proximity sensor

and punching cylinder operation. The last option is STOP.

Buyers looking

forward to buy advanced technology Automatic Punching Machine are requested to

examine the details of different designs available at Tradeindia. With plenty

of choices available, buyers will no more have to look beyond Indiaa s leading

B2B portal for purchasing the machines. Shortlist your products and send your

requirements to us. We will be pleased to serve you with the best business

deals here.

Client Testimonials & Reviews

HarinderKumar

STAR PACKAGING SYSTEMS

We have been associated with tradeindia.com from last 7 years. A genuine company which actually provides the services they offer through a helpful staff. Highly recommended to anyone looking to start or expand business joint with tradeindia. It is a very good platform to export ourselves. Thanks tradeindia.com.

Kalpesh

PURUSHARTH PACKAGING

We are associated with tradeindia since last 7 years. We are much satisfied with the service and response from tradeindia. We are having many client through online marketing. We wishes best future for tradeindia

SureshSisodiya

DURGA PACKAGING MACHINE

We are the member of tradeindia.com. We are getting very good inquiry/responses through tradeindia.com, We are satisfied with the support of CRM department. We looking forward the same kind of support and relationship from tradeindia and wishing them best for their future.

AshishJoshi

ASHUTOSH ENTERPRISE

We are the member of the tradeindia.com for the last six years. We have good inquiries through tradeindia.com, we are satisfied by the services and inquiry received by tradeindia.com. We are looking forward the same kind of support and relationship from tradeindia.com. We wish all the best for the tradeindia.com for the future.

BhaveshMehta

MONARCH APPLIANCES PRIVATE LIMITED

We are leading manufacturer of Packaging Machinery. We are associated with tradeindia since 11 years. We are very satisfied with the response getting through tradeindia. We would really like to appreciate the working of tradeindia.com and their team members. We would like to continue with them in the ensuring years. We wish you all Good Luck in their future endeavors.

VinayJain

APROTECH ENGINEERS PVT. LTD.

We are associated with tradeindia for past twenty years. During this period, we are regularly getting enquiries and hence renewing our contract continuously. Tradeindia are competitive in the field.

SanjaySabharwal

UFLEX LIMITED (ENGINEERING DIVISION)

We are the manufacturer and exporters of Packaging and converting machinery based at Noida, India. We are regular Advertiser of tradeindia.com and getting relevant inquiry. We are satisfied from the service provided by tradeindia.com. We Wish all the very best to tradeindia family for an excellent future.

Ch. UmaRao

PRESTO PACK SYSTEMS PVT. LTD.

We have been associated with tradeindia since more than 10 years and we feel happy to say that their services have been excellent during our courtship and has become our effective marketing tool to explore Domestic and International Market. We wish to continue with their improving services in years to come. We would like tradeindia to keep this good work and promote the Indian Market more. All the Best for tradeindia team.

K.Srinivas

CANFLEX ENGINEERING PVT. LTD.

We, M/S Canflex Engineering (manufacturers of Packaging Machinery) are proud to be associated with M/S Infocom Network Ltd, Since 10 years. We are having good business relationship till date and in hope to continue the same in near future too. We, wish that your company continues to contribute more to promote our products in Domestic as well as International markets.

Fakharuddin

SARA UDYOG

We are Manufacturer and Exporter of Auger filler machines, Automatic filling and packing machine, Automatic pneumatic packing machine, Band sealer, coding pan, Collar type machine, Drum roster, Liquid mixer machine, Manual padal sealing, Pouch packing machine with Auger filler, Packaging Machine, Snax food scooder machine, Collar type filler, Line packaging machine, Masala packaging machine, Chips Plant, Gutaka plant, Kurkure machine plant, Namkeen plant, Food processing machine, Tea packaging machine. We are working on enquiry on daily basis, we are satisfied with tradeindia services this is one of the good B2B portal. We are getting relevant enquiry. We wish all the very best to tradeindia family for their excellent future.

Automatic Punching Machine Price List

This Data was Last Updated on 2025-12-21

Automatic Punching Machine Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Polygraf General Industries Mumbai, India | 17 Years |

Fair Deal Engineers Faridabad, India | 13 Years |

Ga-mor Machine Tools Pvt. Ltd. Bengaluru, India | 12 Years |

Zs Enterprise Co., Ltd. Dongguan, China | 12 Years |

Disposable Machinery Kolkata, India | 11 Years |

Zenith Engineering And Equipments Private Limited Vadodara, India | 11 Years |

Kamtronics Technology Private Limited New Delhi, India | 11 Years |

Vishwakarma Engineering Works Surat, India | 11 Years |

Sheetal Enterprises Ahmedabad, India | 10 Years |

Care Polypack Pune, India | 10 Years |

Upcoming Tradeshows

CWIEME Shanghai 2026

Wed, 24 Jun, 2026 - Fri, 26 Jun, 2026

INDOMACH Jamshedpur 2026

Thu, 05 Feb, 2026 - Sun, 08 Feb, 2026

Asia Photonics Expo (APE 2026)

Wed, 04 Feb, 2026 - Fri, 06 Feb, 2026

IFF - India Fashion Forum 2026

Wed, 28 Jan, 2026 - Thu, 29 Jan, 2026

Plastic Packaging Printing Expo (P3) 2026

Fri, 10 Apr, 2026 - Mon, 13 Apr, 2026

STEEL CONSTRUCTION EXPO 2026

Thu, 26 Feb, 2026 - Sat, 28 Feb, 2026

Panacea - Natural Products Expo India 2026

Fri, 06 Mar, 2026 - Sun, 08 Mar, 2026

India Boat & Marine Show 2026

Thu, 29 Jan, 2026 - Sat, 31 Jan, 2026

Spectra Expo 2026

Wed, 06 May, 2026 - Fri, 08 May, 2026

Odisha Mining & Infrastructure International Expo 2026

Thu, 08 Jan, 2026 - Sun, 11 Jan, 2026

Popular Categories