Welding & Soldering Supplies

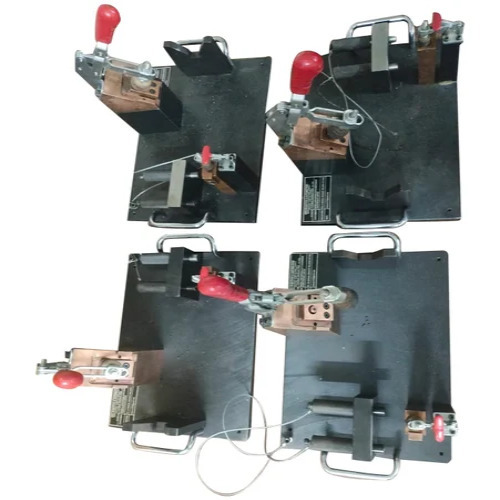

(2475 products)Handle Clamp

Price: 4550 INR/Piece

MOQ100 Piece/Pieces

Supply Ability100 Per Week

Delivery Time1 Week

Axis Electrical Components (i) P. Ltd.

Mumbai

Esab Welding Wire Roll Application: Industrial

Price: 3000 INR/Piece

Usagelow carbon alloy steel welding

ApplicationIndustrial

ColorAs Shown In Product Image

SizeAs Per Order Or Availability

Product TypeWelding Equipment

MaterialSS, MS, Aluminium/Aluminium Alloy, Copper/Copper Alloy, Other

Jayant Impex

Mumbai

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller4 Years

Rust Free High Strength Durable Mig Welding Wire

ApplicationFor Welding Purpose

UsageFor Industrial

Product TypeMig Welding Wire

Precise Alloys Pvt. Ltd.

Mumbai

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller18 Years

Rectangle Wire Mesh Gender: Unisex

ColorMetalic

Size(per inch) 50-100 , 100-150, 150-200, 0-10, 10-50

Product TypeExpanded Wire Mesh

MaterialSS316, Fine SS, Other

Indo German Wire Screen Co.

Mumbai

Trusted Seller

Trusted Seller Super Seller

Super Seller11 Years

Plastic Welding Rods For Fabrication Of Plastic Components Application: Soldering Works

Price: 212.00 INR/Piece

MOQ200 Piece/Pieces

ApplicationSoldering Works

UsageCommercial and Industrial Use

Sangir Plastics Pvt. Ltd.

Valsad

Trusted Seller

Trusted Seller Super Seller

Super Seller10 Years

Mig Wire - High-Quality Welding Wire | Durable, Precision Engineered for Optimal Performance

Price Trend: 50000.00 - 100000.00 INR/Ton

MOQ16 Ton/Tons

FOB Portkolkata

Payment TermsOthers, Cash in Advance (CID), Cash Advance (CA)

Supply Ability8000 Per Month

Nirmal Wires (p) Ltd.

Kolkata

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller Super Seller

Super Seller7 Years

Exothermic Welding Powder - Size: Comes In Various Sizes

Price: 2200 INR/Kilograms

MOQ10 Kilograms/Kilograms

ApplicationElectrical Grounding

Product TypeExothermic Welding Powder

UsageUsed in electrical grounding to create strong, permanent connections between conductors through a high-temperature chemical reaction.

Veraizen Earthing Pvt. Ltd.

Vasai

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller2 Years

Dross Ash Application: Industrial

Price: 1100 INR/Kilograms

MOQ300 Kilograms/Kilograms

ApplicationIndustrial

MaterialOther

Samir Enterprises

Vasai

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller Premium Seller

Premium Seller7 Years

Pvc Welding Curtain - Application: Cuirtan

Price: 1000 INR/Piece

MOQ1 Piece/Pieces

UsageCuirtan

Size6 X 6 Feet

ApplicationCuirtan

ColorBlack,Blue,Red

Product TypePVC Welding Curtain

MaterialOther, PVC

Gurukrupa Bellows Pvt Ltd

Pune

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller10 Years

MAXFIL- 40R Rutile Type Flux Core Welding Wire

Price Trend: 500.00 - 2000.00 INR/Piece

MOQ10 , Piece/Pieces

Supply Ability50 Per Week

Delivery Time1 Week

D & H Secheron Electrodes Private Limited

Indore

Trusted Seller

Trusted Seller Super Seller

Super Seller5 Years

Exothermic Welding Mould - Color: Black

Price: 4000 INR/Piece

MOQ2 , Piece/Pieces

Product TypeGraphite Mould for having Exothermic Welds

UsageIndustrial

ColorBlack

Ai Earthing

Vapi

Trusted Seller

Trusted Seller Super Seller

Super Seller9 Years

Exweld Mini F-C Welding Machine Application: Industrial

Price: 3800 INR/Unit

MOQ1 Unit/Units

Product TypeWelding Machine

ApplicationIndustrial

MaterialStainless Steel

Nay Enterprise

Ankleshwar

Trusted Seller

Trusted Seller Super Seller

Super Seller13 Years

PP ABS UHMWPE Nylon Rod - Industrial Grade Material, Black & Green | High Impact Resistance, Excellent Corrosion Resistance, Thermal & Electrical Insulation

Price: 275 INR/Kilograms

MOQ1 , Kilograms/Kilograms

ApplicationIndustrial

Product TypeNylon Rod

ColorBlack & Gray

MaterialOther

Isan Exim Plastotech Private Limited

Thane

Trusted Seller

Trusted Seller Super Seller

Super Seller13 Years

Ventilation Fume Exhaust Blower - Color: Blue Yellow

Price: 45000 INR/Piece

MOQ10 Piece/Pieces

Operating Voltage240 Volt (V)

ColorBlue Yellow

UsageIndustrial

SizeStandard

MaterialOther, Mild Steel

Laxmi Udyog

Mumbai

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller14 Years

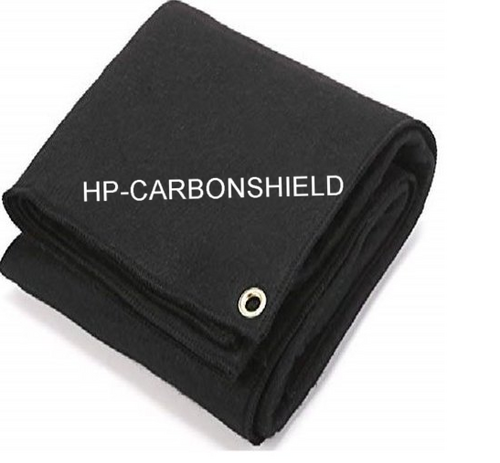

Carbon Fiber Fire Welding Blanket - Black | Commercial Use, Flame and Spark Protection

Price Trend: 900.00 - 1050.00 INR/Square Meter

MOQ1 Square Meter/Square Meters

ColorBlack

UsageCommercial

Hemnil Protection

Mumbai

Trusted Seller

Trusted Seller Super Seller

Super Seller13 Years

Multifunctional Rework Station Model - Sharang 609D

Product DescriptionMultifunctional Rework Station Model - Sharang 609D

Sharang Corporation

Pune

Trusted Seller

Trusted Seller Super Seller

Super Seller17 Years

Solder Wire - 60/40 Composition, 22 SWG Thickness | Ideal for Precision Electronics Applications

Price: 1600 INR/Piece

MOQ10 Piece/Pieces

Product DescriptionSolder Wire

Shweta Electronics

Mumbai

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller17 Years

Robust Rubbers Wire Mesh

Product DescriptionWith significantly better current practical knowledge, we have the potential to export, manufacture, distribute, supply and trade a wide range of Rubber Wire Mesh in Ahmedabad, Gujarat, India to our considered customers. The offered ranges is manufactured by our professionals applying ideal quality

Gaylord Enterprise

Ahmedabad

Trusted Seller

Trusted Seller Super Seller

Super Seller11 Years

Brown Vermiculite Coated Welding Blanket

Price Trend: 100.00 - 600.00 INR/Square Meter

MOQ30 Square Meter/Square Meters

Usagewelding, foundry works, aluminium and steel mills, boiler insulation and seal, exhaust systems, shipyards, refineries, power plants and chemical plants.

Product TypeWelding Blanket

Length30 0r 50 Meter (m)

ColorBrown

Weight1 Grams (g)

Width1 Meter (m)

Darshan Safety Zone

Ahmedabad

Trusted Seller

Trusted Seller Super Seller

Super Seller6 Years

Soldering Stations - High-Performance Electronic Workbench , Durable and Versatile for Various Applications

MOQ1 Piece/Pieces

Sample AvailableYes

Sample PolicyContact us for information regarding our sample policy

Main Export Market(s)Asia

Aroindia Electromech Pvt. Ltd.

New Delhi

Trusted Seller

Trusted Seller Super Seller

Super Seller8 Years

Speedglas Welding Shield

Product DescriptionWe are amongst one of the foremost organization engaged in manufacturing and supplying a superior range of Speedglas Welding Shield in Delhi, India.Our offered shield is highly demanded among the customers for protecting face from the welding sparks. The offered shield is developed with the help of

ESAB 308L Rutile Flux Cored MIG Wire For SS Welding - Stainless Steel, Ideal for SS MIG Welding | Optimal Performance, Versatile Use

Price: 490 INR/Kilograms

MOQ10 Kilograms/Kilograms

UsageSS MIG Welding

Product TypeMIG Wire For SS Welding

MaterialStainless Steel

Esab India Limited

Chennai

Trusted Seller

Trusted Seller Super Seller

Super Seller4 Years

Standardized Ultrasonic Plastic Welder

Product DescriptionWith the professional workforce of our organization, we manufacture, export and supply a huge array of Standardized Ultrasonic Plastic Welder in Ahmedabad, Gujarat, India. This range of Ultrasonic Plastic Welder is designed and manufactured employing quality assured and with the help of sophisticate

Sheetal Enterprises

Ahmedabad

Trusted Seller

Trusted Seller10 Years

Exothermic Welding - High-Strength Bonding Solution | Unmatched Quality, Expert Service

Product DescriptionOwing to our rich practice, we provide an exclusive range of Exothermic Welding to the clients in this industry. Our offered this product is the strong bond the welding provides is unmatched. In order to maintain the quality of this service, it is provided to clients by some of our highly experience

Soldering Iron 100 Watt - Application: Industrial

Price: 695 INR/Piece

MOQ100 Piece/Pieces

ApplicationIndustrial

Operating Temperature50 - 480 Celsius (oC)

Product TypeSoldering Iron 100 Watt

SizeAll size

Rishabh Overseas

Mumbai

Trusted Seller

Trusted Seller Premium Seller

Premium Seller2 Years

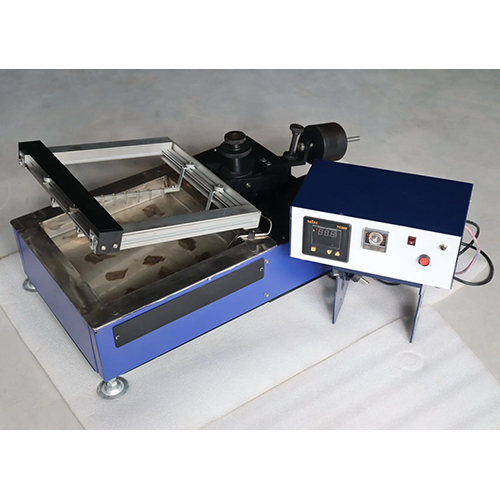

Automatic Dip Soldering Machine Dip 905 - Material: Stainless Steel

MOQ1 Unit/Units

Operating Voltage220 Volt (V)

SizeVarious Sizes Available

UsageIndustrial

MaterialStainless Steel

CoatingPolished

Yontro Mechatronic Systech

Gurugram

Trusted Seller

Trusted Seller Premium Seller

Premium Seller1 Years

Pipe Rotator - Automatic Grade: Automatic

Price: 300000.00 INR/Set

MOQ1 Set/Sets

TypePipe Rotator

Automatic GradeAutomatic

Admech Equipment (india) Pvt. Ltd.

Indore

Trusted Seller

Trusted Seller Super Seller

Super Seller9 Years

Stainless Steel Industrial Laser Cutting Head

Price: 195000 INR/Unit

MOQ10 Unit/Units

SizeCustomized

UsageIndustrial

Product TypeIndustrial Laser Cutting Head

Weight3 Kilograms (kg)

MaterialStainless Steel

Lavanya Enterprise

Ahmedabad

Trusted Seller

Trusted Seller Super Seller

Super Seller4 Years

Popular Welding & Soldering Supplies

Welding Equipment And Their Uses

Introduction

Welding is the method of joining two materials by applying heat and/or pressure to them in order to melt or solidify the bond between them. In either case, the resulting connection is referred to as a seam or weldment. Welding involves the use of concentrated, intense heat to melt the filler metal and the original metal together under the protection of a shielding arc made of gas unique to the type of welding machine being used.

- Protection gear including welding gloves, aprons, and helmets, as well as dust masks and fume extractors

- Tools like wire brushes and chisel hammers.

- Equipment for metal-arc welding (MIG/MAG) including gas nozzles and contact tips

- Welding electrodes made of tungsten used in TIG and GTAW processes

- Discs made of abrasive materials, used in angle grinders

- Spot welding resistance electrodes

What Is Welding Equipment For Beginners?

1. FCAW

My advice is to begin with a Flux-Cored Arc Welding (FCAW) system if you have no idea what you're doing. Gasless MIG is a common (and inaccurate) name for this welding technique. It's one of the least expensive and least time-consuming to master. Like aiming and shooting at targets.

2. TIG

My recommendation is a TIG welding machine for anyone looking to join aluminum or stainless steel. These need more effort to master and a larger financial investment, but they offer greater flexibility. Welding mild steel presents no difficulties either.

3. Multipurpose Machines

Most of the time, you'll get the most for your money by investing in a multifunctional machine that can plasma cut as well as weld steel and stainless.

Nowhere else can you have such a wide selection of features at such a low cost? Having two Welding Equipment functions in one convenient device is a reality thanks to its plasma cutting capability.

Depending on what you have on hand, you can switch the wiring to use either 110v or 220v. If you can, try to use 220 volts to achieve the best results.

4. Welding Gear

Having a welding helmet that automatically darkens is a huge time saver. Some of them can cost hundreds of dollars, which is completely unreasonable. They're great, but it's tough to make a case for them.

Different Types of Welding Equipment Kit

1. Welding Jackets

Welding requires us to wear jackets constructed from materials that can withstand high temperatures without catching fire. There are many options when it comes to jackets, but the best ones will last you for many years without needing to be replaced.

2. Welding Gloves

Heavy-duty tasks typically call for this. Spatter can seriously injure your hands, but these gloves will keep them safe. Try to find gloves with several layers of insulation. Silicone patches add an extra layer of protection against heat and splatter for some of the most robust MIG welding gloves.

3. Welding Helmets

When welding, it's important to wear a quality helmet to shield your face and neck from harmful particles in the air. Without the protective gear, the arc's strong radiation can quickly destroy your skin and eyes. Welding helmets with automatic opening mechanisms are often favored.

4. Cables

Cables are used to transmit electrical current. Copper or aluminum are used to create the cables, and they are flexible. Most cables consist of 900-2000 twisted wires.

5. Electrode Holders

The electrode holders are used to keep the electrodes at the correct angle during the procedure. Based on their current capacities, the electrode holders come in a variety of sizes. The amperage ratings range from half a hundred to five hundred.

Similarly, the electrode diameters determine the sizing requirements for the electrode holders. The larger electrode is needed to support the heavier current of the 300-Ampere machine, as opposed to the 100-Ampere machine. Because inadvertent short-circuiting can occur while using non-insulated holders, they should be avoided.

6. Welding Machine

In the welding world, both alternating current (A.C.) and direct current (D.C.) machines are equally at home. An inverter is built into the A.C. welding equipment.

This transformer functions as a step-down regulator, decreasing the 220 or 440 V input to either 80 or 100 V. The motor-generator set for the D.C. welding equipment is alternating current (A.C.).

In contrast to A.C. machines, which have a power factor of just 0.3–0.4, D.C. machines have a power factor of 0.6–0.7.

7. Welding Pliers

Many of us are familiar with pliers in general, but what do you know about welding pliers in particular? Forged steel is utilized in the construction of welding pliers, which are employed in a wide variety of welding procedures. With the help of a spring, you may effortlessly open and close them.

They've been subjected to various heat treatments to increase their durability.

Pliers designed specifically for welding are most commonly employed during the MIG welding process. You can use them to clean the nozzles, cut wire, and get rid of splatter.

8. Electrode

In a sense, the electrode is the beating heart of the welding process. The welding process involves the transfer of energy from the welder to the workpiece via the tool's tip. Electrode tips used in TIG welders are often made of tungsten, which is not a consumable material.

In contrast to other welding methods, TIG welding doesn't require electrode replacement.

9. Spot Welding machine

Spot welding, a type of resistance welding, involves applying pressure and heat to the weld region using electric current in order to join two or more metal sheets. These machines' benefits include efficient use of energy, a rapid production rate, easy automation, etc.

10. Thyristor MIG Welding Machine

Precision and hard ground parts of the highest quality are used in the production of these sorts of welding equipment. To mount or repair objects, this welding equipment is widely considered the best option. In particular, solid core and flux materials are ideal for these machines.

11. Shielded Metal ARC Welding Machine

Generally speaking, the heat generated by an electric arc is the driving force behind the operation of shielded metal arc welding devices. Stick welding refers to this method of joining metal together with a stick and an electric current (filler rod). Both alternating current (AC) and direct current (DC) can power SMAW machines.

12. Flux Core ARC Welding Machine

Most commonly, flux core welding equipment are used to join thick metals. Welding is accomplished by applying heat from an electric arc to the joint location to melt the base metal and permanently unite the two pieces.

13. Energy Beam Welding Machine

The machine employs a concentrated beam of fast-moving electrons, guided by magnetic fields, to combine the components. Energy beam welding equipment may join two different metals of different thicknesses together.

14. Atomic Hydrogen Welding Machine

The AHW device makes use of hydrogen gas from a cylinder and the arc created between two tungsten electrodes. Welding with atomic hydrogen is so called because the arc breaks the hydrogen atoms apart.

15. Safety TIps while using Welding Equipment

Welders should always follow these basic safety procedures, which are based on industry standards:

- Except in cases where exposure studies show that workers are not at risk of overexposure, all welders should wear a respirator that meets current regulations.

- I'm checking out the electrode holder and other welding gear before getting started.

- When using an electrode holder, welders should take care to avoid getting their skin or wet clothing in contact with the metal components.

- Workers should safeguard their eyes and head by donning protective gear such welding helmets and goggles when handling hot slag, sparks, bright light, or chemicals.

- To check for any smoldering flames, welders should stay in the work area for at least 30 minutes after they've finished their shift.

- Welding requires the use of gas cylinders, which are under tremendous pressure. Protect yourself and others from the intense heat by keeping a safe distance from any sparks or slag that may fly off.

- Avoid slips, trips, and falls by keeping your workplace clear of debris. Work in dry places and avoid confined spaces.

- Do not put on any synthetic fabrics.

- You should put on some goggles or safety glasses after taking off your welding helmet to keep slag out of your eyes.

- Welding on coated materials like galvanized or cadmium plated steel will emit harmful vapors and should be avoided. Keep away from chemicals when welding.

Conclusion

Machines or equipment for welding comes in a wide variety of forms and can be used to a wide variety of uses. When working with welding and cutting equipment, it's imperative that workers wear protective gear to ensure their own safety. Welding machine upkeep is a breeze with just a little forethought and organization.

FAQs: Welding Equipment

Q. What is the equipment required in welding?

Ans. Here are some common equipment for Welding:

- Welder

- Feeds

- Safety Gear

- Charged Electrode

- Wire

Q. Which is the best welding equipment for home use?

Ans. Millmermatic 252 is the best welding equipment for home use. In terms of output current, the Millermatic 252 can deliver up to 300A. This makes it possible to maintain a higher welding output for a longer period of time, which is useful for prolonged procedures.

Q. What are some of the best welding equipment brands?

Ans. Here are some top reputable welding equipment manufacturing brands in India:

- Electra

- Vulcan

- Panasonic

- Esab India

- Virdi

- Akira Engineers

- Arm Welders

Q. How does welding equipment work?

Ans. Welding equipment works where a metal workpiece is grounded to the welding machine and an electrode is hooked to the welding machine, creating a molten weld.

Manufacturers & Suppliers of Welding & Soldering Supplies

Company Name | Member Since |

|---|---|

Precise Alloys Pvt. Ltd. Mumbai, India | 18 Years |

Sharang Corporation Pune, India | 17 Years |

Shweta Electronics Mumbai, India | 17 Years |

Axis Electrical Components (I) P. Ltd. Mumbai, India | 15 Years |

Laxmi Udyog Mumbai, India | 14 Years |

Allied Power Solutions Delhi, India | 14 Years |

Nay Enterprise Ankleshwar, India | 13 Years |

Isan Exim Plastotech Private Limited Thane, India | 13 Years |

Hemnil Protection Mumbai, India | 13 Years |

Indo German Wire Screen Co. Mumbai, India | 11 Years |

Popular Products