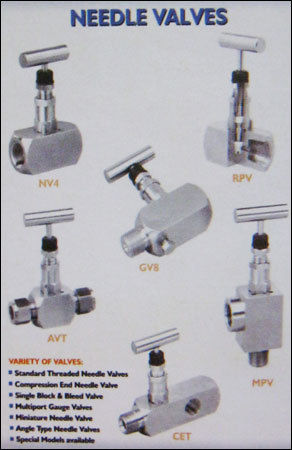

Needle Valves

(1167 products)Hydraulic Needle Valves - Corrosion-Resistant, 1/4 to 1 Inch BSP Size, Galvanized Finish | Long Functional Life, Chemical Resistance, High Performance

Price: 200 INR/Piece

MOQ1 Piece/Pieces

Product TypeHydraulic Needle Valves

UsagePipelines

Size1/4 to 1 1/4

StructureNeedle

MaterialOther

Surface TreatmentGalvanized

Jacktech Hydraulics

Ahmedabad

Trusted Seller

Trusted Seller Super Premium

Super Premium13 Years

Super Premium

Super PremiumStainless Steel Plug Valves - Screwed Bonnet Design Double Ferrule

Price Trend: 200.00 - 2000.00 INR/Piece

MOQ100 Piece/Pieces

StructurePlug

MaterialStainless Steel

A Saluji Engineering Works

Mumbai

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller12 Years

SS Needle Valve - Stainless Steel, Galvanized Silver Finish | Industrial Application, Control Flow Rates of Clean Gasses and Fluids

Price: 5000 INR/Piece

MOQ1 Piece/Pieces

Product TypeSS Needle Valve

UsageControl Flow Rates Of Clean Gasses, Fluids

ColorSilver

ApplicationIndustrial

StructureNeedle

MaterialStainless Steel

Aditya Engineering Works

Vadodara

Trusted Seller

Trusted Seller Premium Seller

Premium Seller7 Years

Corrosion Resistant High Strength Brass Needle Valve

MOQ100000

ApplicationFor Commercial

Product TypeBrass Needle Valve

UsageFor Commercial

ColorGolden

MaterialBrass

Surface TreatmentPolishing

Bhargav Brass Industries

Jamnagar

Trusted Seller

Trusted Seller Premium Seller

Premium Seller14 Years

Heavy Duty Needle Valves - Stainless Steel 304 & 202, 1/2 & 3/8 Size, Manufactured with Advanced Technology

Payment TermsOthers, Cash Against Delivery (CAD)

Main Domestic MarketAll India

Motexo Industries Llp

Rajkot

Trusted Seller

Trusted Seller Super Seller

Super Seller7 Years

Industrial Needle Valves - Stainless Steel, 1/8-1' Size | Ideal for Liquid and Gas Flow Control, Medium Pressure Use, Galvanized Finish

Price: 1200 INR/Piece

MOQ20 Piece/Pieces

ConnectionOther

Product TypeIndustrial Needle Valves

ColorGray

UsageIndustrial

ApplicationIndustrial

StructureNeedle

Bhagyalaxmi Engineering Works

Ahmedabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller9 Years

Rigid Needle Valve

Product DescriptionADVANTAGES :\015\012Pioneer Needle valves have metal to metal seats with fine threaded screw down. This enables positive sealing up to the capacity of the valve.\015\012Pioneer valves are made from forged brass body with SS304 spindle and PTFE washer which gives extended service life. All valves are

Pioneer Industries

Mumbai

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller18 Years

SS Needle Valve - Stainless Steel, Multiple Sizes, Grey | Easy Installation, Precise Flow Control, Corrosion-Resistant, Leak-Proof Design

Price: 300 INR/Piece

MOQ1000 Piece/Pieces

UsageIndustrial Use

SizeMultiple

ConnectionThread

ColorGrey

Product TypeSs Needle Valve

StructureNeedle

Mahi Exporters

Mumbai

Trusted Seller

Trusted Seller Premium Seller

Premium Seller3 Years

Stainless Steel Needle Valve - Color: Metallic Grey

Price: 250 INR/Piece

MOQ100 Piece/Pieces

UsageIndustrial

ColorMetallic Grey

MaterialStainless Steel

Surface TreatmentPolishing

MediaWater

Jirawala Pipe & Tube

Mumbai

Trusted Seller

Trusted Seller Premium Seller

Premium Seller2 Years

Handmade Flowjet Needle Valves

Product DescriptionBacked by rich industry experience, we are engaged in exporting, manufacturing and supplying of Needle Valves in Ahmedabad, Gujarat, India. These offered products are manufactured using supreme grade quality components that is sourced from reliable vendors of the market keeping in mind set industry

Flowjet Valves Pvt.ltd

Ahmedabad

Trusted Seller

Trusted Seller Super Seller

Super Seller4 Years

1/2" BSP Brass Needle Valve - Multi-Purpose Application, High/Low/Medium Pressure | Brass Material, Needle Structure, Polished Surface Treatment

Price: 500 INR/Piece

MOQ10 Piece/Pieces

Product TypeBrass Needle Valve

StructureNeedle

MaterialBrass

Surface TreatmentPolishing

PressureOther

PowerOther

Super Hydro Pneumatic

Navi Mumbai

Trusted Seller

Trusted Seller Premium Seller

Premium Seller6 Years

Industrial Needle Valve - Stainless Steel, 80x35x70mm, Silver | High-Pressure Water Control, Metal Seat, Up to 15000 Psi, -54°C to +538°C

Price: 900.0 INR/Piece

MOQ5 Piece/Pieces

Temperature of Media500 Celsius (oC)

SizeStandard

ColorSilver

ApplicationWater, oil, acid, nuclear waste, other

ConnectionThread

Width35 Millimeter (mm)

Pressure Valves Private Limited

Ahmedabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller1 Years

Unitech Systems

Ahmedabad

Trusted Seller

Trusted Seller Super Seller

Super Seller14 Years

S.S. Needle Valve Screwed End And Flanged End

Product DescriptionOur organization have been actively engaged in manufacturing, exporting, distributing, trading and supplying a premium quality S.S. Needle Valve Screwed End and Flanged End in Ahmedabad, Gujarat, India. The offered valve is manufactured using rich grade raw material and advanced manufacturing techni

Universal Engineering

Ahmedabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller19 Years

Hign Pressure Needle Control Valves - Color: Silver

Price: 1250 INR/Piece

MOQ20 Piece/Pieces

ColorSilver

UsageIndustrial

ConnectionOther, Screw End

MaterialOther, Mild Steel

Surface TreatmentPowder Coated

MediaGas

Techno Engineering And Solutions

Pune

Trusted Seller

Trusted Seller Premium Seller

Premium Seller1 Years

1 Inch Bspf Line Female Valve Application: Industrial

Price: 10500 INR/Unit

MOQ5 Unit/Units

ColorGolden

SizeDifferent Size

Product Type1 Inch BSPF Line Female Valve

ApplicationIndustrial

UsageIndustrial

StructureNeedle

Maharashtra Multi Distributors Ltd.

Pune

Trusted Seller

Trusted Seller Premium Seller

Premium Seller3 Years

Needle Valve - Precision Engineered, Manual and Self-Adjustable Flow Control for Plumbing and Commercial Applications

Product DescriptionBeing a clients centric organization, we are engaged in manufacturing, trading, wholesaling and supplying a precisely designed range of Needle Valve that are made by our by us using superior quality raw material. Most of our valves have to be manually operated except in some cases where self adjustm

Kamal Metal Industries

Mumbai

Premium Seller

Premium Seller1 Years

DPL Needle Valves

Product DescriptionNeedle Valves\015\012Product Description :\015\012Two stage shut off, fine regulation and combination of different material and end connection available. Sizes range from 1/8" to 2".\015\012\015\012Application :\015\0121. Chemical, Petrochemical, Fertilizer and food processing industries.\015\0122

Dpl Valves & Systems Pvt. Ltd.

Mumbai

Trusted Seller

Trusted Seller Super Seller

Super Seller15 Years

Needle Valve Manufacturer In Surat - Color: Silver

Price: 2000 INR/Unit

MOQ1 Number

SizeStandard Sizes

Product TypeSs Needle Valve

UsageIndustrial

ColorSilver

StructureControl

Flowbiz Exports Private Limited

Ahmedabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller3 Years

SS Needle Valve - Stainless Steel, 1/4 inch Size, Silver Color - Precise Flow Control, Corrosion Resistance, Durable, Versatile for Chemicals and Beverages

Price: 245 INR/Piece

MOQ50 Number

Product TypeSS Needle Valve

Size1/4"

UsageIndustrial

ColorSilver

MaterialStainless Steel

Chamunda Engineering Solutions

Ahmedabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller5 Years

Silver Heavy Duty Ss Needle Valves

Price: 150.00 INR/Piece

MOQ1 Piece/Pieces

Product TypeSS Needle Valves

UsageUsed for Pipe Fitting

ColorSilver

MaterialStainless Steel

PressureHigh Pressure PSI

Kitex Piping Solutions

Mumbai

Trusted Seller

Trusted Seller Super Seller

Super Seller7 Years

Stainless Steel Needle Valve - 6000psi Pressure, 500F Temperature Resistance | Safe Union-Bonnet Design, Panel Mountable, 100% Factory Tested

Product DescriptionWe are the standout organization which has gained name and fame in distributing and supplying a top quality range of Stainless Steel Needle Valve in Vadodara, Gujarat, India. The durable construction values of these valves allow them to successfully handle working pressure up to 6000psi as well as

Shivani Traders

Vadodara

Trusted Seller

Trusted Seller10 Years

Silver High Pressure Neddle Valve

Price: 550 INR/Unit

MOQ1 , Unit/Units

UsageIndustrial

ColorSilver

Product TypeNeedle Valve

SizeDifferent Available

MaterialOther

Surface TreatmentPolishing

Ivm Engineering

Ahmedabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller4 Years

Portable And Durable Stainless Steel Ferrul Needle Valve

ApplicationIndustrial

UsageIndustrial

Product TypeFerrul Needle Valve

ColorSilver

MaterialStainless Steel

Surface TreatmentPolishing

S. S. Equipment

Delhi

Trusted Seller

Trusted Seller Premium Seller

Premium Seller8 Years

HINDUSTAN Needle Valves - Stainless Steel, Threaded Connection, 1000 psi | Corrosion Resistant, Durable, Versatile Flow Rate

Product DescriptionObtainable from us is a exclusive assortment of Needle Valves. We fabricate these valves by implementing sophisticated machines and technologies as per the global quality standards superior quality material assuring reliable and sleek functioning. These Needle Valves are broadly required to be used

SS Needle Valve - Brass 2 Inch , Silver Industrial Needle Valve with Precise Flow Control

Price: 300 INR/Piece

MOQ100 Piece/Pieces

Size2 inch

Product TypeSS Needle Valve

ColorSilver

UsageIndustrial

MaterialBrass

B. S. Hydro Pneumatics Private Limited

Mumbai

Trusted Seller

Trusted Seller7 Years

Needle Valves

Price: 250 INR/Piece

MOQ100 Piece/Pieces

UsagePrecise flow control in fluid systems

Product TypeFlow Control Valve

ColorSilver

ApplicationChemical, Petrochemical, Water treatment, Hydraulic, and Laboratory systems

MaterialStainless Steel

MediaWater

SS Needle Valve

Price: 200 INR/Piece

MOQ10 Piece/Pieces

Payment TermsCash in Advance (CID), Cheque

Supply Ability100 Per Week

Delivery Time2-7 Days

Kastur Industries

Mumbai

Trusted Seller

Trusted Seller Super Seller

Super Seller11 Years

Latest From Needle Valves

Integral Bonnet Screwed Ends Needle Valves

By:

Gautam Steel Center

Forged Body Needle Valves

By:

Dhaval Enterprise

Popular Needle Valves

Needle Valves Types, Working & Uses

Introduction

Needle valves are a type of valve used to control the flow of fluids like gas or water in many applications. The little plunger, which resembles a needle, is the item's defining characteristic. The valve may be turned with ease and precision using the handwheel-like grip on the plunger.

The extended end of the valve is designed to precisely fit into the seat, located on the device being controlled. Turning the valve, however, creates a gap between the needle and the seat, allowing only a trace quantity of substance to escape.

Roles of Needle Valves

-

1. Air Regulation

-

2. Turbine by-Pass

-

3. Flow Control

-

4. Pressure Regulation

-

5. Reservoir Inlet

-

6. Flow Discharge

-

7. In Pump Start

Needle Valves Types

The needle valve is utilized in situations when a highly accurate flow measurement is required. Needle valves are more resistant to differential pressure than diaphragm valves. Needless to say, needle valves are not used with slurries or other viscous media since the small aperture is rapidly clogged by thick material or particles.

There are two primary varieties of needle valves, both of which are discussed here.

a) - Inline Needle Valve

The ports for inflow and outflow on these valves are aligned in a straight line. In most cases, a straight line flow system is the best option for installing these valves.

b) - Angle Needle Valve

The inlet and output of these valves are at an angle. The inlet and the outlet are often set at right angles to one another for seamless integration into the system. This valve is installed at a 90-degree turn in the pipe system.

Parts of a Needle Valve

1. Handle

A valve's manual operation is performed via a handle located outside the valve body. In most cases, automatic valves don't have handles, although a stop-check valve, for example, might provide a way to override the system.

2. Set Screw

When mounting a pulley or gear to a shaft, for example, a set screw is used to tighten the component against the shaft by pressure and/or friction. To distinguish it from a bolt, a set screw is often used without a nut and is threaded into a hole bored into just one of the two items being fastened. Set screws are sometimes known as grub screws or blind screws since their entire length is threaded rather than just the tip.

3. Stem

The power screw on the stem converts the rotational motion of the hand wheel into a vertical motion, which is then sent to the plug, where it is used to seat the disc in its seat and seal off the flow opening.

In order to connect the stem of the valve to the hand wheel, there are four flat edges at the top that thread into the power screw and are then locked in place with a nut.

The disc stem nut is used to connect the plug into the stem at the bottom. The stem will experience torsional forces generated by the power screw.

4. Body

Valve bodies, often called shells, are the primary component of needle valves. The body is the primary part of a valve assembly since it is the structure that holds everything in place. The body, or initial pressure barrier, of a valve is what holds back the pressure of flowing fluid in the pipes that are connected to it.

5. Gland

The packing gland is a component of the valve that is put into the bonnet to keep the stem packing in place. The top of the packing gland is used in conjunction with the bottom bearing set of the stem adapter to ensure the Needle Valves operate smoothly.

6. Bonnet

The opening of the valve is closed by the bonnet. The valve's body serves as the service load bearing element of the device, supporting the full pressure of the fluid being routed through the valve. It is secured using a threaded stud and nuts.

The gland is supported by the bonnet, which in this case is composed of bronze because that is the same material used for the valve body.

7. Other Parts

Packing, Stem, Nut, Handle Screw, O Ring and others are some main parts of Needle Valve

Needle Valves Working

To stop or start the flow of liquid or gas via a tube, a needle valve relies on the idea of restricting or allowing the movement of the needle section of the valve. Let's analyze the steps involved. While there are many moving parts within a needle valve, the needle and the seat are the most crucial for the valve to function. The needle is the conical plunger that can be retracted from the channel or pushed into it to regulate the flow. The point at which a needle enters a pipe carrying fluid or air is called its "seat." The seat is the depression into which the needle fits. Both the needle and the seat are made to be precise fits in their respective locations.

When the needle is in place and pressed all the way down, there will be no spaces through which gas or liquid can escape. It was on purpose that they came out to be just the right size. The needle valve's exterior features a handle that the user can hold and attach to the valve's stem. This handle can take the form of a bar handle or a rounded handle. The needle is threaded like a screw and inserts into the seat from the inside. The needle valve is activated by turning the stem, which is done by grasping the handle in a manner that allows for effortless rotation. The threaded sides turn as the needle spins, allowing you to raise or lower the needle from its seat.

Needle depth changes are disguised by the threading, so they are barely perceptible at each turn. With this, the needle's position may be adjusted to within a few hundredths of a degree, allowing for the greatest possible precision. Once the flow is stopped, the observant mind may immediately recognize the possible danger of the entire component becoming over-pressurized and being unable to withstand the resulting pressure. However, the reality remains that the item's compact size is what allows it to function. As the aperture is relatively small in relation to the rest of the body, high pressure is not an issue. On the other hand, the restricted flow rate is usually not a good fit for the small opening.

Needle Valve Uses

They excel in small channel applications requiring precision flow regulation and accurate calibration. Many different types of businesses rely on needle valves for fluid control. The following are just a few of the many uses for a needle valve:

-

(i) - In order to regulate the flow of liquid, a needle valve is built into all analog field instruments.

-

(ii) -When a controlled, steady reduction in flow rate is required, needle valves come in handy.

-

(iii) -The needle valve functions as both an on/off switch and a control for the flow rate.

-

(iv) -Steam, air, gas, oil, and water are just few of the fluids for which this can be used as a meter.

-

(v) -When only a small amount of flow is needed at a sample point in the pipe, a needle valve comes in handy.

-

(vi) -The gas bleeder lines can use this valve.

-

(vii) -When precise flow management is necessary, automated combustion control systems use needle valves.

-

(viii) -Combined with a constant pressure pump governor, it smoothes out the flow from the pump and minimizes fluctuations.

Many different needle valves can be used to control the flow rate through a pipe or other opening; this is a function shared by all valves. However, each kind has its own set of pros that may make it better suited to some jobs than others. Needle valves have their own unique benefits; yet, this does not make them the greatest valve available. Rather, it is more appropriate to say that the needle valve is the optimum valve when extreme precision and accuracy are required, such as in the scenarios we discussed.

FAQs: Needle Valves

Q. What is a needle valve?

Ans. The needle valve is a specific kind of valve characterized by an extremely constrained port and a plunger in the shape of a needle that can move up and down in the valve's opening. It gets its name because it looks like a needle inside a syringe.

Q. What is the advantage of needle valve?

Ans. Here are the advantages:

-

(i) -This valve allows for precise control of flow at low rates.

-

(ii) -Tiny needle valves are used. Since this system does not require a lot of room to set up, it can be easily installed in almost any environment.

-

(iii) -This valve enables throttling with a reduced fluid volume.

-

(iv) -A fine degree of control is available over the flow rates.

-

(v) -The system can be used with less effort.

Q. What are needle valves used for

Ans. Chemical processing, Low-pressure hydraulic systems, and other gas and liquid services frequently employ needle valves. Due to the materials used, these valves can be used in environments with high temperatures and oxygen.

Q. What is difference between needle valve and ball valve?

Ans. A ball valve's sole purpose is to open and close. If possible, keep your engine from being slowed for too long while Needle valves' versatile designs allow for on/off, throttling, and precision metering operation, giving you a wide range of control over the flow of fluid.

Manufacturers & Suppliers of Needle Valves

Company Name | Member Since |

|---|---|

Universal Engineering Ahmedabad, India | 19 Years |

Pioneer Industries Mumbai, India | 18 Years |

Hindustan Hydraulics & Pneumatics Chennai, India | 18 Years |

Dpl Valves & Systems Pvt. Ltd. Mumbai, India | 15 Years |

Bhargav Brass Industries Jamnagar, India | 14 Years |

Unitech Systems Ahmedabad, India | 14 Years |

Jacktech Hydraulics Ahmedabad, India | 13 Years |

A Saluji Engineering Works Mumbai, India | 12 Years |

Priti Enterprises Mumbai, India | 12 Years |

Kastur Industries Mumbai, India | 11 Years |

Popular Products