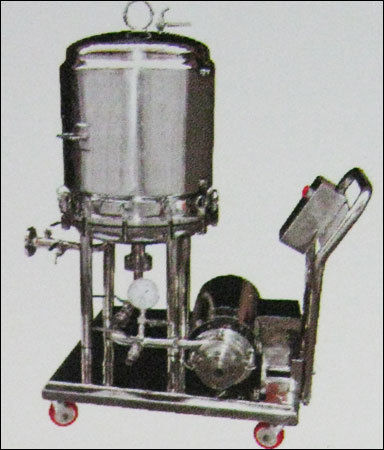

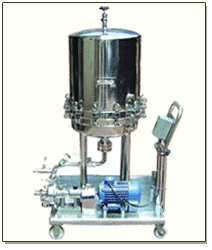

Zero Hold Filter Press By Pharma Equipments & Technologies

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Stainless steel |

| Pressure | 0.1-10 kg/cm2 |

| Type | Horizontal plate |

| Usage | Liquid-solid separation, clarification, and filtration of various materials |

| Cake drying | Air/Inert gas |

| Filtration media | Various types |

| Construction | SS304/SS316/SS316L |

| Features | Closed system, Full recovery, Easy cleaning, Low maintenance, High efficiency, Uniform cake, Reduced costs |

Product Overview

Key Features

- Our Zero Hold Filter Press is known for it's rust proof surface finish, unmatchable performance, reliability, longer working life, negligible maintenance cost and easy usage.

- This is accessible in a variety of promised sizes and specifications as per the needs of the clients.

Features:

- It has been actively involved in the manufacturing of various types of filter press for filtration systems for more than eight years viz. sparkler, spiral, bag, leaf, neutsche, etc.

- It now adds one more to its range by introducing a new generation of Zero Hold-up Horizontal Plate closed pressure filter, made first time in India for clarification and separation of solids from liquid.

- Our normal practice, the filter press is thoroughly tested in our factory & proved before releasing for marketing.

Salient Features:

- Central feeding of Unfiltered liquid ensures :

- Single pass clear filtration

- Full Batch recovery of the filtrate.

- No Scavenging of the filtrate.

- Complete Cake retains on the Plate.

- Uniform distribution of cake on each plate.

- Reduce the cost of treatment of Catalyst, Toxic Chemicals.

- Less Exposure to the operating person.

- No contamination of the internal surface of the Shell.

Closed System ensures:

- Filtration of Toxic, Hazardous/ Unit can be sterilised.

Equal thickness of the Cake on each plate ensures:

- Minimum amount of solvent required to wash the Active Material from the Cake

- Reduce the cost of expensive solvents.

- Cake can be thoroughly dried either by compressed air or by inert Gas.

- Uniform Filter - Aid Bed can be formed.

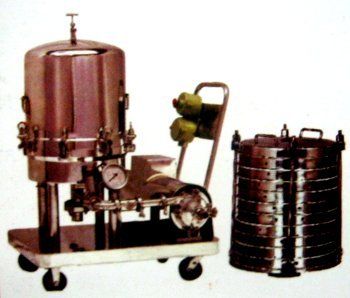

Plate pack arrangement ensures:

- Any type of filtering media singularly or in combination, can be used to achieve required micro efficiency. Easy removal and cleaning of the Cartridge Assembly.

Additional provision of External Tightening Arrangement ensures:

- Tightening of the Cartridge, Assembly during Filtration.

Working Pressure :

- Minimum 0.1 Kg / Cm2 & maximum 10 kg/cm2

Material of Construction :

- Stainless Steel : SS 304 / SS 316 / SS 316 L

WORKING :

- The Cartridge assembly consists of plates, perforated screens, spacers and fitter media. Interlocking spacers internally form single pipeline. The unfiltered liquid is centrally fed under pressure from bottom inlet. The liquids spreads out equally on each plate fitted with filter media. Solids remain on filter media and clear. filterate flows through precisely made holes on sides of plates and collects in the shell, which then comes out through the outlet. In this process, solids are evenly distributed on each plate. At the end of the cycle the cake can be dried by applying compressed air or inhert gas.

Company Details

Focusing on a customer-centric approach, PHARMA EQUIPMENTS & TECHNOLOGIES has a pan-India presence and caters to a huge consumer base throughout the country. Buy Pharmaceutical Machinery in bulk from PHARMA EQUIPMENTS & TECHNOLOGIES at Trade India quality-assured products.

Business Type

Manufacturer, Supplier

Employee Count

25

Establishment

2016

Working Days

Monday To Sunday

GST NO

27AVOPM2792C1ZB

Payment Mode

Online Payments (NEFT/RTGS/IMPS), Cheque/DD

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 27AVOPM2792C1ZB

Nalasopara, Maharashtra

Proprietor

Mr Vikas Ghare

Address

Gala no. 2/A, Krishna Industrial Estate, Avdhoot Ashram Road, Nallasopara Phata(E), Nalasopara, Maharashtra, 401208, India

Report incorrect details