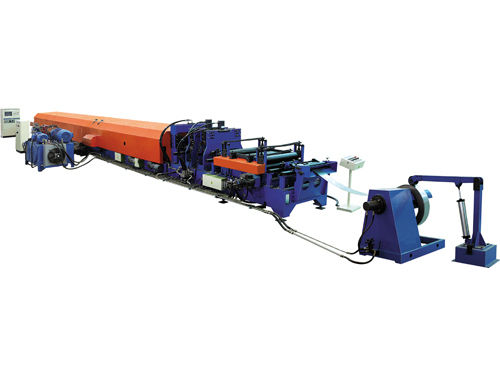

Z Purlin Forming Machine - Galvalume & Galvanized Steel, 1.5mm To 3.2mm Thickness | High Efficiency, Low Maintenance, Hassle-free Operation

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Galvalume Steel |

| Thickness | 1.5Mm To 3.2Mm |

| Motor Power | 15 Kw |

| Hydraulic Power | 5.5 Kw |

| Roll Forming Speed | 8-10 M/Minute |

| Cutting Tolerance | +/-2.5Mm To +/-3.0Mm |

| Weight | 7000Kg |

| Features | High Efficiency, Low Maintenance, Hassle-Free Operation, Excellent Performance, Accurate Dimensions, Durable Construction, Versatile Application, Easy Operation |

Product Overview

Key Features

Z Purlin Forming Machine

With firm commitment to quality, we are involved in manufacturing, exporting and supplying the wide range of Z Purlin Forming Machine. This machine is majorly used in steel industry for forming Z purlin with accurate dimensions. Offered machine is efficiently manufactured under the strict guidance of specialized professionals by make utilization of topnotch quality components and the latest techniques. Further, this Z Purlin Forming Machine can get from us in different specifications as per the varied needs of the clients.

Special Key Features:

- High efficiency

- Low maintenance

- Hassle-free operation

- Excellent performance

Main Technical Specifications:

| Material specification | galvalume, galvanized steel and carbon steel. |

| Thickness | 1.5mm to 3.2mm. |

| Main motor power | 15 kw. |

| Hydraulic station power | 5.5 kw. |

| Feeding width | changeable. |

| Cover width | changeable. |

| Yield stress | 235Mpa(33KSI) ~ 345Mpa (50KSI). |

| Roll forming Speed | 8 ~ 10 m/minute. |

| Cutting Tolerance | +/-2.5mm(length5000mm); +/-3.0mm(5000mm<length10000mm). |

| Manual Uncoiler | Max. Capacity: 3000kgs. |

| Coil inner diameter | 508mm. |

| Voltage | As per customers request. |

| Numbers of stands | 17 stands/stations/pairs. |

| Type of cutting | Roll-formed and length-set profile cutting. |

| Total weight | About 7000kg |

| Voltage | as customer's requirement |

Material of Main Equipment:

| Roller Material | GCr15 bearing steel, with quenching treatment. |

| Active Shaft Material | High grade No.45 carbon wrought steel,which can improve the integrated mechanic feature of the shaft. |

| Electric Elements | PLC control panel, transducer imported from Mitsubishi of Japan. Other elements are from famous suppliers of China. |

| Cutter blades | Cr12 mould steel with quenched treatment. |

Specifications:

| Forming Capacity | ||||

| H | A | B | C | t(mm) |

| 100 | 50 | 52 | 15 | 1.6~2.0 |

| 125 | 50 | 52 | 15 | 1.6~2.3 |

| 150 | 65 | 67 | 18 | 2.3~3.2 |

| 200 | 75 | 77 | 20 | 2.3~3.2 |

| 250 | 75 | 77 | 20 | 3.0~3.2 |

Company Details

Business Type

Exporter, Manufacturer, Distributor, Supplier, Trading Company

Establishment

2004

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Hangzhou, Zhejiang

Sales Manager

Ms Juliette

Members since

6 Years

Address

Room 2511, Taigu Plaza, Jingcheng Road, Xiaoshan District, Hangzhou, Zhejiang, 311202, China

purlin in Hangzhou

Report incorrect details