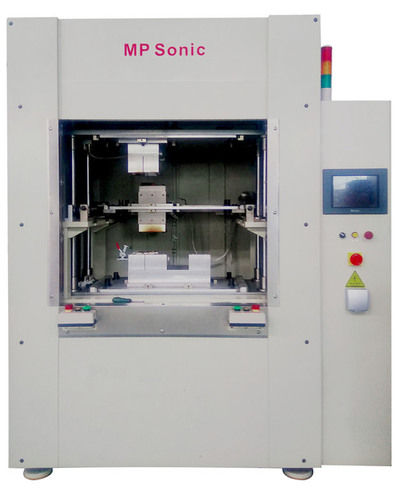

Vibration Welding Machine - 2800~8000 Kilograms, 160~650 Square Millimeter Welding Area | Advanced Plastic Joining, Automatic Resonance Tuning, Digital Process Control, Infrared Pre-heating Optional

Price Trend: 33000.00 - 32000.00 USD

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Power | 23~47K Watt (w) |

| Cooling Method | Air Cooling |

| Weight | 2800~8000 Kilograms (kg) |

| Type | Vertical |

| Frequency | 15~260 Hertz (HZ) |

| Condition | New |

| Input Current | 100~250 |

| Usage | Vibration thermoplastic joining |

| Voltage | 220/380 Volt (v) |

| Welding Area | 160~650 Square Millimeter (mm2) |

| Function | Plastic welding |

| FOB Port | Ningbo |

| Payment Terms | Telegraphic Transfer (T/T), Cash in Advance (CID), Cash Advance (CA) |

| Supply Ability | 50 Per Month |

| Delivery Time | 35~90 Days |

| Packaging Details | Wooden Case |

| Main Export Market(s) | Australia, South America, Eastern Europe, Western Europe, Middle East, Central America, Africa, Asia, North America |

| Main Domestic Market | All India |

| Certifications | CE & ISO * SGS |

Product Overview

Key Features

I. Advantages of vibration plastic welding:

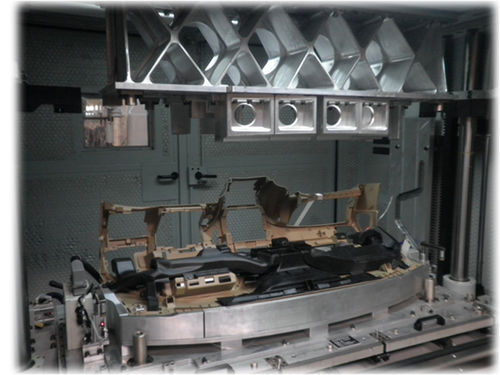

1. High welding ability: vibration welding is applied to finish the most challenging thermoplastic joining in large welding size, challenge material such as nylon, complex geometric shape design, etc;

2. Perfect welding result: strong welding strength, airtightness and no mark on the shown surface;

3. Effective plastic joining, vibration welding cycle time normally is 20~30Sec;

4. Low power consumption compared to hot platen welding, the power consumed by the vibration system only during vibration;

5. Clean welding, no smoke generated during vibration welding;

6. Can achieve welding process control and supervision digitally.

Zhenbo.MP-Sonic imported the linear vibration friction plastic joining technology from Korea. Before putting MP-Sonic vibration welding machine into the market, we were devoted into the improvement the vibration technique from Korean for two years to optimize the machine system design, and have our machines test by old customers to ensure its welding performance, running stability and duration. MP-SONIC doesn't only apply Korean vibration plastic vibration welding technology, but absolutely master the complete set of technique, from the raw material & elements to the whole system & machine, as well as the entire vibration plastic welding procedure, by which MP-SONIC can improve & optimize it constantly.

MP-SONIC vibration plastic welding machine applies critical parts and material from Europe, USA, Japan or Korea basing on condition, to ensure its perfect vibration plastic welding performance and the stable machine running, while MP-SONIC manufactures & assembles the complete machine in China to reduce machine cost which is under strict control to ensure machine quality.

Now MP-Sonic has standardized the vibration plastic welder specification from 15~200KG, include:

1. MSV-515LS: 15KG;

2. MSV-630LS: 30KG;

3. MSV-650LS: 40KG;

4. MSV-715LS: 55KG;

5. MSV-730LS: 70KG;

6. MSV-830LS: 150KG;

7. MSV-930LS: 200KG.

MP-Sonic MSV series vibration welder almost covers all the specification requirement in the market basing on qualified welding performance & operation stability as well as machine duration.

To achieve the perfect welding performance, we provide an infrared pre-heating system to our vibration welding machine as an optional feature basing on customer requirement.

Features of MP-SONIC Vibration Welder:

1. Automatic resonance tuning;

2. Welding process control, 8 stages welding set;

3. Welding controlled in time mode or Depth mode;

4. 80 sets of welding parameters storage;

5. Welding result judge for QC assistance;

6. Internet connection;

7. Printer connection.

Optional Features: Infrared module for pre-melting.

Welcomed to contact for welding analysis in free.

Company Details

Business Type

Exporter, Manufacturer, Supplier

Employee Count

50

Establishment

2012

Working Days

Monday To Sunday

Payment Mode

Cash Against Delivery (CAD)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Wenzhou, Zhejiang

Commercial Director

Mr Alex Lee

Address

No 289, Weiqi Road, Yueqing Economic Development Zone, Wenzhou, Zhejiang, 05963412, China

vibration welding machine in Wenzhou

Report incorrect details